Nuestra máquina de formación de cuchillas en espiral está diseñada para procesar láminas de metal (acero al carbono, acero inoxidable, etc.) en cuchillas en forma de espiral (de 8 a 30 mm de grosor) para transportadores, utilizada en maquinaria agrícola, maquinaria de protección ambiental, maquinaria minera, industria química, medicina y otras industrias. Puede adaptarse a diferentes tamaños y especificaciones, con un grosor de lámina de 2 a 30 mm.

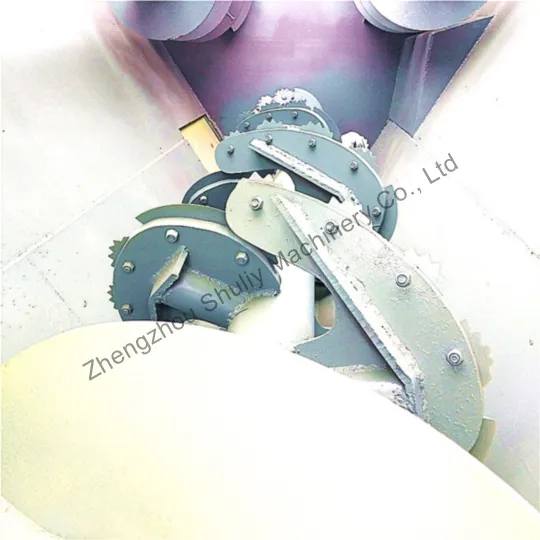

Through continuous pressing and rotational forming, this auger screw forming machine transforms flat metal materials into spiral blades with specific pitch and diameter, enabling functions like conveying, propulsion, and mixing. Interested? Below is a detailed introduction to this auger spiral screw blade making machine. Please continue reading for more information.

Two types of spiral blade forming machines for sale

Shuliy Machinery, as a professional manufacturer of auger flight cold rolling machines, offers two types of equipment: single-piece spiral blade forming machine and continuous cold-rolling spiral blade machine. Both types can be customized according to customer requirements for processing blades of varying thicknesses, diameters, and materials.

Type 1: Sectional spiral blades forming machine

This type is ideal for thicker metal materials and requires manual assistance during operation. It is widely used in agricultural machinery, mining equipment, chemical mixing apparatus, and related industries.

- Processable thickness: 8-30mm

- Processable blade diameter: 200×2 inner diameter to 700×2 inner diameter(mm)

- Applicable materials: Carbon steel, stainless steel, wear-resistant plate, etc.

- Features: High forming precision, adapting to materials of varying hardness, suitable for producing large or heavy-duty equipment components.

Technical parameters of auger screw forming machine

| Modelo | 250—12 | 350—16 | 350—25 | 500—16 | 800—25 |

| Processing diameter(mm) | 200*2 inner shaft dia. | 300*2 inner shaft dia. | 300*2 inner shaft dia. | 400*2 inner shaft dia. | 700*2 inner shaft dia. |

| Processing pitch(mm) | 100—500 | 100—700 | 100—700 | 100—1000 | 200—1500 |

| Maximum sheet thickness(mm) | Carbon steel 12 Stainless steel 10 Wear-resistant plate 6 | Carbon steel 16 Stainless steel 12 Wear-resistant plate 8 | Carbon steel 25 Stainless steel 20 Wear-resistant plate 16 | Carbon steel 16 Stainless steel 12 Wear-resistant plate 8 | Carbon steel 25 Stainless steel 16 Wear-resistant plate 16 |

| Mold height(mm) | 260 | 355 | 355 | 500 | 850 |

| Power(KW) | 4 | 5.5 | 7.5 | 7.5 | 11 |

| Source | 380V, 50Hz | 380V, 50Hz | 380V, 50Hz | 380V, 50Hz | 380V, 50Hz |

| Appearance size(mm) | 2200x500x1200 | 2700x550x1200 | 2700x550x1200 | 2900x650x1350 | 2900x650x1350 |

How does this auger spiral screw blade making machine work?

The screw flight blade cold rolling machine uses hydraulic pressure to insert metal sheets into molds for pressing and shaping. Manual operation is required during the pressing process. Through rotational pressing, the machine achieves a spiral structure, ensuring uniform blade thickness and consistent pitch. The formed blades can be directly welded onto the conveyor shaft, saving time and enhancing efficiency.

Type 2: Continuous screw flight cold rolling machine

This continuous spiral blade forming machine is suitable for mass production of continuous long spiral blades, such as those required for screw conveyors, drilling machines, and auger equipment. It uses cold-rolling forming technology, ensuring consistent pitch and smooth surfaces without requiring post-processing.

- Thickness range: 2-6mm

- Processable sheet diameter: 15-150mm

- Applicable materials: Carbon steel strip, stainless steel, manganese steel, etc.

- Features: High production efficiency, ideal for batch manufacturing. Used for continuous blade production in conveyors, augers, and similar equipment.

Technical data of screw flight forming machine

| Modelo | LX120-5 | LX40-5 | LX150-5 |

| Plate material | SPHC | SPHC, SPHD, SPHE | SPHC, SPCC |

| Voltaje | 380V | 380V | 380V |

| Host power | 15kw*2 | 15kw*2 | 15kw*2 |

| Single side width | 20-120mm | 15-40mm | 20-150mm |

| Sheet thickness | 2-6mm | 2-4mm | 2-6mm |

| Rolling blade inner hole error | ≤±3mm | ≤±3mm | ≤±3mm |

| Rolling blade inner diameter | / | / | 20-600mm |

| Rolling blade outer diameter | 60-750mm | 40-300mm | 80-800mm |

| Rolling blade outer diameter error | ≤±5mm | ≤±5mm | ≤±5mm |

| Rolling blade pitch | 50-800mm | 50-800mm | 50-800mm |

| Rolling blade pitch error | ±5mm | ±5mm | ±5mm |

| Total equipment weight | 4T | 4T | 5.5T |

| Total equipment power | 26KW | 15kW | / |

| Tamaño de la máquina | / | / | 2900*1500*1500mm |

Working principle of continuous cold-rolled spiral blade machine

This auger screw forming machine operates fully automatically throughout the entire process, working with a feed mechanism (feed rack) and a discharge hopper (discharge conveyor platform).

Raw materials enter the rolling die via the feeding system, where they are formed into a continuous spiral shape by two sets of rollers. The entire process employs cold rolling forming, which does not compromise metal strength while delivering high forming speed, low noise levels, and high production efficiency.

Advantages of Shuliy spiral blade forming machine

- Wide processing range: Suitable for metal materials of varying thicknesses and diameters.

- Compatible with multiple materials: Capable of processing carbon steel, stainless steel, wear-resistant plates, and more.

- High precision and efficiency: Automated forming, precise control of pitch, thickness, and diameter, guaranteeing blade consistency with minimal error.

- Labor cost savings: Automatic feeding and pressing minimize manual intervention.

- Customizable design: Tailor molds and blade specifications according to customers’ industry applications, material and size requirements.

Applications of spiral blade cold rolling machine

Spiral blades are widely used in various material conveying and processing equipment, thus this machine has important applications in many industries, including:

- Agricultural machinery: Grain conveyor, mixer, and feed processor

- Mining machinery: Drilling rig, and mineral processing screw conveyor

- Environmental equipment: Sludge conveyor, and waste material conveyor

- Chemical industry: Powder and granular material conveying and mixing equipment

- Pharmaceutical and food industries: Material conveying and mixing system

With its outstanding forming precision and processing capabilities, Shuliy’s screw spiral blade forming machine is the ideal choice for enhancing production efficiency and product quality across these industries.

What’s the spiral blades forming machine price?

The price of a spiral blade cold rolling machine primarily depends on factors such as model, processing thickness range, material, and whether it is customized. Generally, continuous cold rolling mills are suitable for small to medium-sized production lines with lower costs, while single-piece hydraulic forming machines are better suited for large factories or wear-resistant material processing, requiring a slightly higher investment.

Shuliy Machinery can recommend the most cost-effective solution based on the customer’s budget and production capacity requirements.

Why choose Shuliy auger screw forming machine?

Compared to similar equipment on the market, Shuliy boasts over 15 years of manufacturing experience, with equipment exported to more than 80 countries. We provide comprehensive after-sales service and customization support.

Beyond standard models, we design and produce the spiral blade forming machine based on customer drawings or samples. Additionally, Shuliy offers installation guidance, operational training, and technical consultation to ensure stable and efficient operation after equipment commissioning.

Caso de éxito: máquina formadora de hélice vendida a Chile

A client from Chile, engaged in environmental machinery manufacturing, required spiral blades for sludge conveyors. Based on the client’s specifications, Shuliy recommended a cold-rolled spiral blade making machine. After installation and commissioning, the blades delivered precise dimensions and smooth surfaces, earning the client’s full satisfaction. They expressed intent to procure additional units later to expand their production line.

¿Está interesado en esta máquina formadora de espiral de cuchillas? Si es así, ¡bienvenido a contactarnos en cualquier momento! ¡Proporcionaremos la solución más adecuada para beneficiar su negocio! Además, tenemos otras máquinas de reciclaje de metal en venta, como:

¡Contáctenos ahora para obtener un presupuesto!