La máquina de corte de anillos de neumáticos Shuliy se utiliza principalmente para separar la banda de rodadura, el flanco y el talón (incluyendo el talón de alambre de acero) de neumáticos de nylon y neumáticos de alambre de acero con un diámetro entre 650 mm y 1250 mm. Es el primer proceso para el reciclaje de neumáticos usados, manejando 40 piezas de neumáticos por hora.

Este cortador de flancos de neumáticos es un equipo de descomposición preliminar con fácil operación y alta eficiencia. Es uno de los equipos de apoyo clave de la línea de procesamiento de neumáticos usados. Si estás interesado en el reciclaje de neumáticos de goma, ¡te invitamos a contactarnos para más detalles!

Ventajas de la máquina de corte de anillos de neumáticos usados

- Puede corta 40 neumáticos por hora, completando uno en 3 minutos.

- Nuestro cortador de pan de neumáticos es adecuado para neumáticos de nylon y alambre de acero, rango de diámetro aplicable de 650-1250 mm.

- La máquina de desmontaje de neumáticos adopta dispositivos de bloqueo superior e inferior, fijando efectivamente los neumáticos y haciendo que el proceso de corte sea más seguro.

- Su la cabeza cortadora está hecha de material de aleación de alta resistencia, con una larga vida útil y un bajo costo de mantenimiento.

Parámetros técnicos de la máquina cortadora de neumáticos de goma

Los siguientes son los parámetros técnicos detallados de la máquina de ranurado de neumáticos Shuliy, adecuada para configuraciones de plantas de reciclaje de neumáticos pequeñas y medianas.

| Nombre | Máquina cortadora de pared lateral de neumáticos |

| Potencia del motor | 4 KW+0.75KW |

| Capacidad | 40pcs/h |

| Rango de trabajo | ∮650-1250 mm |

| L*W*H | 1.8m*1.3m*1.6m |

| Peso | 650 kg |

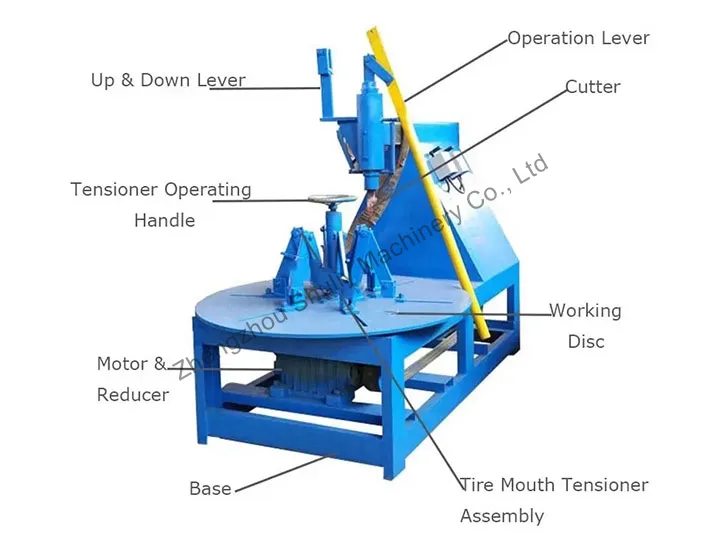

Estructura de la máquina de corte de anillos de neumáticos

Nuestro cortador de bead de neumático está compuesto por palancas (palanca de operación, palanca de arriba y abajo), cortador, mango de operación del tensador, conjunto de tensador de boca de neumático, disco de trabajo, motor y reductor, y base.

¿Cómo funciona la cortadora de anillos de pared lateral de neumáticos?

La estructura de la máquina cortadora de anillos de neumáticos está razonablemente diseñada y tiene un módulo claro, y el proceso de trabajo es:

- Colocar el neumático desechado horizontalmente sobre la mesa de trabajo.

- Asegurar firmemente el neumático con los dispositivos de sujeción superior e inferior para evitar deslizamientos durante el corte.

- Ajustar la posición del cortador de aleación para alinearlo con el borde del neumático (es decir, la posición que contiene el anillo de alambre de acero).

- Al iniciar el motor principal, el cortador comienza a girar y cortar el borde del neumático.

- Después de completar el corte, se saca el neumático, y su borde y carcasa se separan suavemente, lo que facilita el ingreso al siguiente proceso.

Todo el proceso está altamente mecanizado, y la operación manual es simple y puede ser realizada por una sola persona.

¿Cuál es el precio de la máquina cortadora de anillos de neumáticos Shuliy?

Como fabricante profesional de equipos de reciclaje de neumáticos usados, Shuliy ofrece diferentes modelos y configuraciones de la máquina cortadora de anillos de flanco de neumáticos. El precio varía según el modelo seleccionado, la configuración del motor y los requisitos de personalización. Si el cliente necesita combinar la línea completa de procesamiento de neumáticos usados (incluyendo cortadora, cortadora de tiras de neumáticos, máquina de polvo de goma), el precio se calculará por separado de acuerdo con el plan de toda la línea.

Para la última cotización, lista de configuración, tiempo de entrega y estimación de flete, por favor contáctenos para una cotización personalizada.

¡Póngase en contacto con nosotros para más detalles!

¿Interesado en el reciclaje de neumáticos de goma? Si es así, contáctenos ahora, díganos sus requisitos, como productos finales, capacidad, presupuesto, etc. ¡Ofreceremos la mejor solución para ayudar a su negocio de reciclaje de neumáticos!