オーストラリアは年間約5600万本の廃タイヤを排出しています。埋立制限政策と循環型経済の目標の進展により、タイヤリサイクルは地域の環境保護産業の重要な要素となっています。

ニューサウスウェールズ州(NSW)や西オーストラリア州(WA)などの地域では、大規模なタイヤリサイクル事業者が、オーストラリアでの高自動化タイヤリサイクル機械を導入し、大規模で規制遵守の処理ニーズに応え続けています。

市場は「単純な切断と処理」から「資源集約型の深いリサイクル」へと進化しており、その核心目的は廃タイヤをクラムゴム、鉄線、繊維、TDF(タイヤ由来燃料)に変換することです。

シュリータイヤリサイクル機のオーストラリア導入

オーストラリアのタイヤリサイクル機械に関して、現在の市場は主に次の機器の組み合わせを採用しています:

タイヤシュレッダー

- 二軸構成

- タイヤを50〜150mmのピースにシュレッド

- スクリーンとコンベヤーベルトとの併用

- 大規模な連続運用に適しています

タイヤグラニュレーター&ゴムミル

- ゴムを10〜40メッシュのゴム粒またはゴム粉にさらに処理

- 道路用ゴムやスポーツ用表面のコア設備

鉄線&繊維用セパレーター

- 高効率磁気分離+空気分類システム

- ゴムの純度を向上させ、オーストラリアの適用基準を満たす

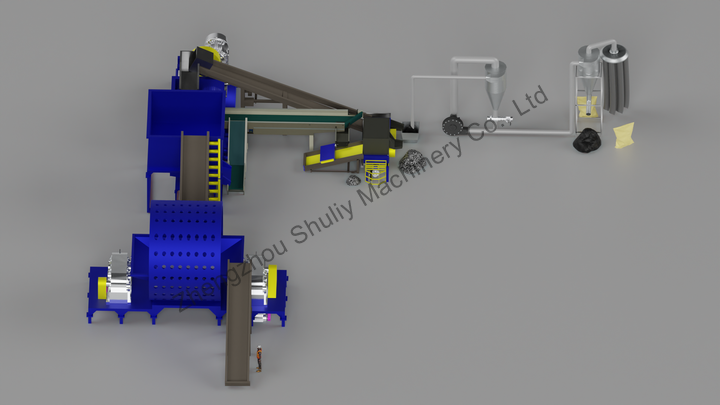

統合自動タイヤリサイクルライン

- タイヤリサイクルプロセス:シュレッディング → 保管 → ミリング → 分別 → 収集

- 労働コストを大幅に削減し、運用の安定性を向上させる

オーストラリア市場におけるシュリーの自動タイヤリサイクルプラントの利点

さまざまなブランドを評価した結果、中規模から大規模のタイヤリサイクル業者の間でコスト効果の高いワンストップソリューションへの関心が高まっています。シュリーは、オーストラリア市場向けに2つの実証済み構成を提供しています:

- ソリューション1:シュレッディング+ゴム粉ライン(セミ自動)

- 鉄線引き出し機 → タイヤカッター → シュレッダー → 自動コンベヤー → 材料保管システム → ゴム粉機 → ナイロンエアセパレーター → 完成品収集

- ソリューション2:高効率フロントエンド前処理ライン(完全自動)

- 統合ビードカッター&リングカッター → タイヤビードセパレーター → シュレッダー → 自動搬送 → ゴム粉研削&選別ユニット → 空気分離

主な利点は:

- 高い自動化レベルで、オーストラリアの高い労働コスト環境に適しています

- 乗用車タイヤとトラックタイヤの両方に対応

- 高純度のゴム粉と広範な適用範囲

- 海外の豊富なプロジェクト経験を活かしたフルラインのカスタマイズをサポート

オーストラリアにおけるゴム粉およびTDF(タイヤ由来燃料)用途の展望

オーストラリアのタイヤリサイクル機械で処理された製品は、広く以下に応用されています:

- 道路用ゴム改質アスファルト

- 子供の遊び場やスポーツフィールド

- ゴムタイルとクッションマット

- TDF代替燃料

政府の調達とグリーンインフラへの投資増加に伴い、リサイクルゴム材料の需要は引き続き拡大しています。

オーストラリアのタイヤリサイクルの解決策を入手!

オーストラリアのタイヤリサイクル産業は、自動化、大規模運営、資源回収への移行を加速させています。オーストラリアで適切なタイヤリサイクル機械を選択することは、環境規制の遵守だけでなく、プロジェクトの回収期間にも直接影響します。

シュリーは、オーストラリア市場で注目の機器ソリューションプロバイダーとして台頭しています

- その実証済みの完全自動タイヤリサイクルライン

- 柔軟な構成ソリューション

- 専門知識ソリューション

📩 お問い合わせいただくと、次の情報を受け取れます:

- オーストラリア向けの適用可能な設定オプション

- 機器見積もりとROI計算

- 実運用動画とケーススタディ