Kartonmolen is meganiese toerusting wat gebruik word vir die versnippering van karton in kleiner stukke of poeier of makliker daaropvolgende verwerking, herwinning of wegdoening. Tipies gebruik in die kartonherwinning, afvalpapierverwerking en papiervervaardigingsindustrieë, help hierdie tipe brekermasjien om die grootte van afval te verminder, papierherwinningsyfers te verhoog en hulpbronvermorsing te verminder. Die hamermeulbreker is gewild vir sy doeltreffendheid, betroubaarheid en geskiktheid vir verskillende groottes en tipes karton, en is een van die onontbeerlike masjiene in die papierbedryf.

Werkende video van papier karton slypmasjien

Beskikbare kartonbreker te koop

Ons bied ’n wye verskeidenheid kartondoosmeulmodelle aan om aan jou verskillende behoeftes te voldoen. Of dit nou vir grootskaalse industriële gebruik of ’n klein kantooromgewing is, ons het die regte meelmeulermodel vir jou. Bly asseblief deur die verskillende modelle hieronder te blaai om die beste een vir jou te vind:

| Model | SL-60 | SL-70 | SL-80 | SL-90 | SL-1000 | SL-1300 |

| Kapasiteit (kg/h) | 800-1000 | 1000-1500 | 1500-2000 | 2000-3000 | 3000-4000 | 4000-5000 |

| Motor (kw) | 22 | 30 | 50 | 55 | 75 | 90 |

| Hamer (st.) | 30 | 40 | 37 | 50 | 105 | 105 |

Ongeag die grootte van jou behoeftes, ons het die regte kartondoosbreker vir jou kartonherwinningsbehoeftes. Voel asseblief vry om ons te kontak vir meer gedetailleerde inligting en hulp om die mees geskikte model vir jou te kies.

Hoe om karton doeltreffend te slyp?

Kartondruk word verkry deur die gebruik van ons kartonmeul, hier is hoe die kartonmaalwiel werk:

Voeding

Die eerste stap is om die karton wat versnipper moet word in die voeropening van die kartonversnipperaar te plaas. Hierdie karton kan weggegooide kartonne, papier of ander papierprodukte wees.

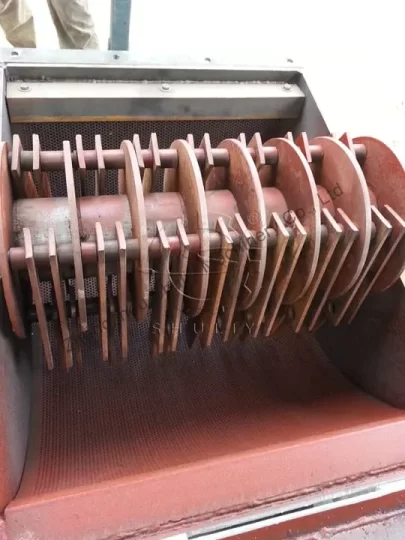

Sny en versnippering

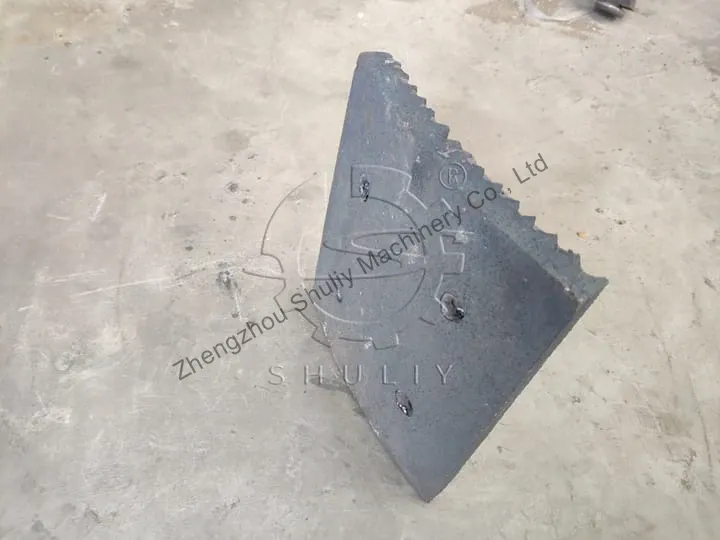

Sodra die karton die masjien binnegaan, word dit aan hoëspoed-roterende snylemme onderwerp. Hierdie lemme, gewoonlik in die vorm van hamers of skeermeslemmetjies, draai en sny die karton in klein stukkies of velle.

Sifting

Die gesnyde karton word in 'n skerm ingevoer, gewoonlik 'n geperforeerde metaalgaas of sif. Die doel van hierdie skerm is om die grootte van die gebreekte deeltjies te beheer. Kleiner gate sal fyn gesnipperde stukke karton produseer, terwyl groter gate groter bonkige stukke sal produseer.

Versameling

Voltooide kartonstukke val deur die skerm in 'n houer of sak vir gesentraliseerde versameling. Hierdie fragmente kan gebruik word vir pulpherwinning, verpakkingsvul of ander hergebruikmetodes.

Voordele van karton grinder

- Grootte verkleining: Kartonslypermasjien kan groot stukke karton vinnig in kleiner stukke of fragmente sny, wat die grootte van karton aansienlik verminder en berging en vervoer vergemaklik.

- Hulpbronherwinning: Gebreekte karton kan herwin word om nuwe papierprodukte te vervaardig, wat help om hulpbronne te bespaar en die las op die omgewing te verminder.

- Veelsydigheid: Hierdie soort kartondoosbreker is geskik vir verskillende soorte karton, insluitend kartonne, papier, verpakkingsmateriaal, ens., en het 'n wye reeks toepassings.

- Betroubaarheid en duursaamheid: Hoë kwaliteit karton slypmasjien het gewoonlik hoë duursaamheid en kan lank stabiel werk, wat instandhoudingskoste verminder.

- Pasmaak: As professionele vervaardigers kan ons pasgemaakte kartonversnippers voorsien om aan klantspesifieke verwerkingsbehoeftes te voldoen.

Ander papierherwinningstoerusting te koop

Ons het 'n reeks papierherwinningsmasjinerie te koop, soos masjien, hidrouliese papierpulper, ens. Besonderhede is soos volg:

Hoe kry u die beste prys vir kartonbrekermasjiene?

Om die beste kartonmeulpryse te kry, moet u betroubare verskaffers en vervaardigers kontak vir kwotasies. Shuliy, as die betroubare vervaardiger en verskaffer van herwinningsmasjiene, kom kontak jy ons en maak dan spesifieke vereistes uit om akkurate pryse te kry.