Die herwinning en hergebruik van polistreinskwimsel (Styrofoam) het ’n belangrike kwessie geword in die konteks van groeiende omgewingsbewustheid. Shuliy Styrofoam densifier bied ’n doeltreffende oplossing vir maatskappye om gebruikers te help om vulling / foam effektief saam te druk en transport- en bergingskoste te verminder.

Hierdie artikel sal fokus op kostedoeltreffendheid, toerustingprestasie en ekonomiese opbrengste oor tyd, en beskryf hoe Shuliy-toerusting waarde vir kliënte skep.

Styrofoam verdikter koste en opbrengs analise

Wanneer 'n skuimkouepers gekoop word, is die eerste ding wat kliënte oorweeg, die aanvanklike beleggingskoste van die toerusting.

Alhoewel die voorafbelegging in 'n skuimkouepers hoog is, verminder dit op die lang termyn aansienlik skuimvervoer- en bergingskoste. Deur die volume tot 1/90 van sy oorspronklike grootte te verminder, kan maatskappye vervoerkoste aansienlik verminder. Veral vir kliënte wat groot hoeveelhede Styrofoam moet hanteer, en die toerusting kan vinnig vir homself betaal.

Boonop verminder die verminderde stoorplekvereistes bedryfskoste en verbeter algehele winsgewendheid.

Kompressiedoeltreffendheid en toerustingprestasie

Nog 'n sleutelfokus vir ons kliënte is kompressie-doeltreffendheid en gemak van werking van die toerusting.

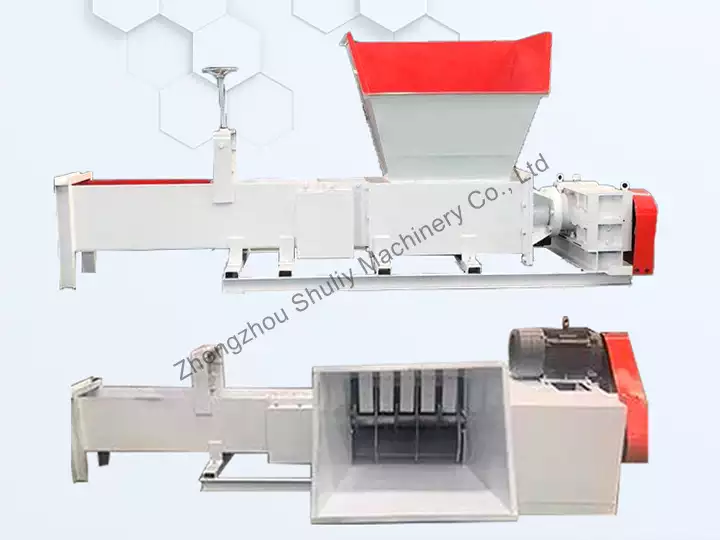

Shuliy Styrofoam compactor is bekend vir sy hoë kompresse-effektiwiteit wat dit toelaat om groot kitchen- / foamvoorsienings in ’n kort tydperk te verwerk. Terselfdertyd is die masjien ontwerp om maklik en veilig te bedryf te word, wat dit geskik maak vir maatskappye van alle groottes.

U hoef nie bekommerd te wees oor tegniese kompleksiteit nie, aangesien ons omvattende installasie- en bedryfsopleidingsdienste verskaf om die gladde werking van die toerusting te verseker.

Onderhoud en na-verkope diens

Baie kliënte is ook bekommerd oor instandhoudingskoste en na-verkope ondersteuning.

Ons skuimkoueperse is robuust gebou en ontwerp vir duursaamheid, wat die behoefte aan gereelde herstelwerk verminder. Daarbenewens bied Shuliy omvattende na-verkope diens en tegniese ondersteuning. Enige probleme wat klante ondervind tydens die gebruik van die toerusting kan dadelik opgelos word. Hierdie moeitevrye na-verkope diens is ook een van die belangrikste redes waarom klante Shuliy-toerusting kies.

Omgewingsvoordele en markvraag

Soos die wêreld meer en meer bekommerd raak oor die omgewing, is kliënte ook bekommerd oor of die toerusting sal help om omgewingsdoelwitte te bereik of nie.

Die skuimkouepers help klante nie net om afvalskuim doeltreffend weg te gooi en stortingsterreinafval te verminder nie, maar bevorder ook die gebruik van herwonne materiaal, wat in lyn is met groenbeleide. Hierdie omgewingsvoordeel stel die kliënt in staat om meer mededingend in die mark te wees en voldoen aan die volhoubare tendense van die toekoms.

Gevolgtrekking

Shuliy se Styrofoam Cold Press bied ’n een-stop oplossing met hoogs doeltreffende kompressievermoë, lae onderhoudsvereistes en uitmuntende after-sales diens. Dit help die kliënt om kostebesparings en marktekskompetisie te realiseer. Is jy op soek na foam-hermeynitingtoerusting? Kontak ons nou om jou foam herwiningsbesigheid te bevoordeel!