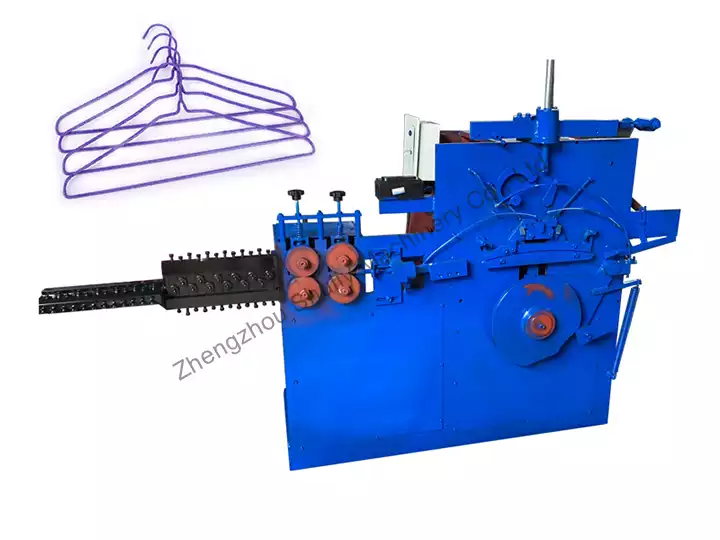

Bu askı üretim hattı, dakikada 30-52 adet giysi askısı kapasitesiyle, plastik kaplamalı çeşitli askı türlerini üretmek üzere tasarlanmıştır.

Tel askı üretim hattı, PVC kaplı askılar yapmak için genellikle hammadde olarak 1,8-3 mm galvanizli teller kullanır. Bu hat yüksek verimlilik, mükemmel otomasyon ve özelleştirme özelliklerine sahiptir.

Ayrıca, askı makinemiz yüksek kaliteli ve çeşitli askılar için küresel pazar talebini karşılayabilir. Bu nedenle, Suudi Arabistan, Kuveyt, Bahreyn, Hindistan, BAE ve diğerleri gibi dünyanın dört bir yanına yaygın olarak satılmaktadır. İlgileniyorsanız, daha fazla ayrıntı için bizimle iletişime geçebilirsiniz!

Tel askı yapma makinesi hattının gücü

- Dakikada 30-52 adet elbise askısı. Makinemiz otomasyon ve sürekli üretim gerçekleştirerek dakikada 30-52 adet askı üretimi yapmaktadır. Oldukça verimlidir.

- Kavisli kanca tipi, sıradan tip, kelebek tipi ve diğer şekillerde elbise askıları üretin. Pazarın farklı taleplerine göre çeşitli elbise askıları üretebilmekteyiz.

- İşçilik maliyetlerini azaltın. Yüksek derecede otomasyon, manuel emeğe olan bağımlılığı azaltır, böylece işçilik maliyetlerini azaltır.

- Özelleştirilebilir voltaj, güç, askı şekilleri vb.. Bunları iş ihtiyaçlarınızı karşılayacak şekilde özelleştirebiliriz.

Elbise askısı yapmak için hammaddeler

Elbise askısı yapımında kullanılan hammaddeler galvanizli tel ve plastik tellerdir. Bu askı üretim hattı için galvanizli teller en uygun olanıdır.

Elbise askısı üretim süreci

Hammaddeyi öğrendikten sonra elbise askısı üretim sürecini ve her adımda kullanılan ekipmanları tanıtacağız.

Adım 1: kalıplama

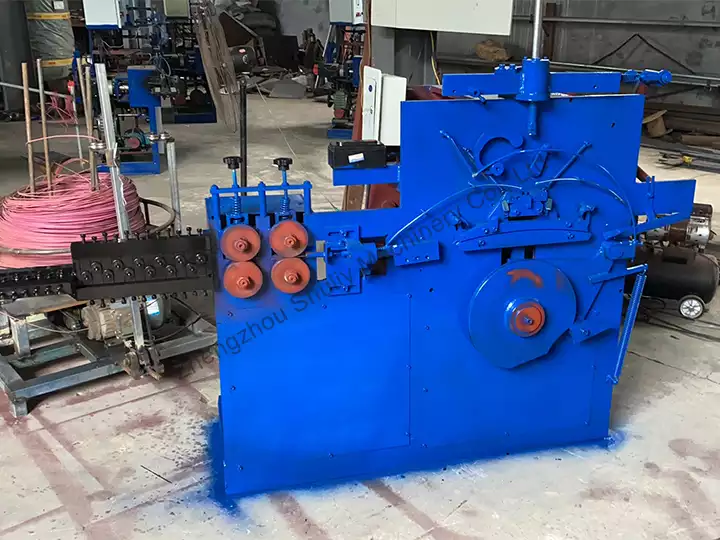

İlk olarak, galvanizli telleri bir askı yapım makinesine besleyin.

Bu makine telleri gerekli şekillerde büker.

| Makine adı | Özellikler |

| Askı makinesi | Kapasite: 30-52 adet/dak Askı boyutu: 11-19 inç |

Adım 2: toz püskürtme ve toplama

Daha sonra galvanizli tel askıların üzerine plastik toz sıkarak askının dayanıklılığını ve görünümünü arttırmalısınız.

Püskürtme işlemi sırasında toz tamamen kullanılmaz ve bir miktar kalıntı kalır. Şu anda toz toplama makinesine ihtiyaç duyulmaktadır.

Bu nedenle genellikle toz püskürtme ekipmanlarımız ve geri dönüşüm ekipmanlarımız şekilde görüldüğü gibi birlikte kullanılmaktadır.

| Makine adı | Özellikler |

| Püskürtme makinesi | Modeli: DMT-23580 Ağırlık: 25kg |

| Toz geri dönüşüm makinası | Modeli: PRM-4 Güç: 3kw Boyut: 1.5*1.1*2 m |

Adım 3: Kurutma

Son olarak püskürtmeli askıları kurutma odasına koyun.

Yüksek sıcaklıklarda toz hızla sertleşir. Güçlü bir yüzey kaplaması oluşturarak askının şeklini ve kalitesini de garanti eder.

| Makine adı | Özellikler |

| Fırın makinesi | Modeli: DMSL-300 Makine boyutu: 3*2.0*1.8m Pişirme sıcaklığı: 180 derece Pişirme süresi: 15-20 dak/saat |

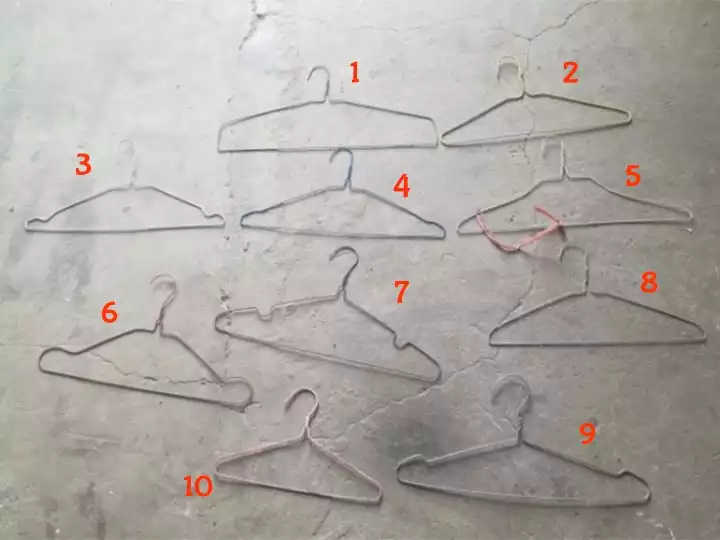

Yapılabilecek elbise askısı çeşitleri

Artık askı imalat sürecini bildiğimize göre üretilebilecek askı şekillerine bakalım.

Farklı ihtiyaçlara uyacak şekilde tasarlanmış birkaç çeşit elbise askısı vardır. En yaygın olanları genel tip askılar, kelebek askılar, kancalı askılar vb.'dir. Detaylar aşağıdaki resimde gösterilmiştir.

Ayrıca askı şeklini taleplerinizi karşılayacak şekilde özelleştirebiliriz. Herhangi bir ihtiyacınız varsa daha fazlası için lütfen bizimle iletişime geçin!

Ne tür Shuliy askı makineleri mevcuttur?

Profesyonel askı makinesi üreticisi ve tedarikçisi olarak üç çeşit askı makinemiz mevcuttur. Daha sonra bunları ayrıntılı olarak tanıtacağız.

- Tip 1: PLC askı yapma makinesi

- Bu elbise askısı makinesi iki tel kullanabilir. Belirli ayrıntılar aşağıda gösterilmektedir:

- Hammaddeler: 1,8-3mm galvanizli teller ve 2-4mm PVC kaplı teller

- Kapasite: Dakikada 30-45 askı

- Özellik: geniş uygulamalar

- Bu elbise askısı makinesi iki tel kullanabilir. Belirli ayrıntılar aşağıda gösterilmektedir:

- Tip 2: tel askı makinası

- Bu tel askı yapma makinesi yalnızca galvanizli telleri kullanabilir.

- Hammaddeler: 1,8-3mm galvanizli teller

- Kapasite: Dakikada 30-45 askı

- Özellik: maliyet etkinliği

- Bu tel askı yapma makinesi yalnızca galvanizli telleri kullanabilir.

- Tip 3: Yüksek hızlı elbise askısı makinesi

- Yeni tip elbise askısı makinesi pazar talebine göre geliştirilmiş olup aşağıdaki özelliklere sahiptir:

- Hammaddeler: 1,7-3mm galvanizli teller ve 2-4mm kaplı teller

- Kapasite: Dakikada 52 askı

- Özellik: standartların altında üretim kalitesiyle askıda kaldığında otomatik kapanma

- Yeni tip elbise askısı makinesi pazar talebine göre geliştirilmiş olup aşağıdaki özelliklere sahiptir:

Shuliy askı üretim hattı fiyatı nasıl?

Askı üretim hattının fiyatı, ekipman çıktısına, üretim hattı konfigürasyonuna, satış sonrası hizmete vb. göre değişir.

Çıkış ne kadar yüksek olursa, ekipmanın konfigürasyonu da o kadar yüksek olur ve fiyat da o kadar yüksek olur.

Genel olarak konuşursak, bir askı üretim hattına yatırım yapmak, en uygun ekipmanı seçmek için kapsamlı bir değerlendirme (üretim ihtiyaçları ve bütçeler) gerektirir. Daha fazlasını öğrenmek istiyorsanız hemen bizimle iletişime geçin!

Tel askı makinesi üretim hattının küresel vakaları

Küresel olarak, tam otomatik tel askı üretim hattı örnekleri geniş bir ülke ve bölge yelpazesini kapsamaktadır. Bu üretim hatları Suudi Arabistan, Umman, Kuveyt, BAE, Hindistan, Cezayir, Ürdün, Yemen, Meksika ve daha birçok ülkeye başarıyla ihraç edilmiştir.

Askıların günlük hayatta ve iş hayatında vazgeçilmez bir eşya olması nedeniyle bu ülkelerde askı makinelerine olan talep giderek artıyor.

Aşağıdaki resimler referans olması açısından bu ülkelere ihraç ettiğimiz askı makinelerimizin yükleme resimleridir.

Askı makinesi üretim hattı, küresel pazarın çeşitlenen taleplerinin karşılanmasında önemli bir rol oynamaktadır. Üretim verimliliğini artırır ve üretim maliyetlerini azaltır. Ayrıca farklı ülkelerdeki askı talebine de güvenilir bir çözüm sunmaktadır.

Hemen teklif alın!

Askı yapımıyla ilgileniyor musunuz? Evet ise, bizimle iletişime geçin ve kapasite, bütçe gibi gereksinimlerinizi bize bildirin. Profesyonel satış ekibimiz en iyi çözümü sunacaktır!