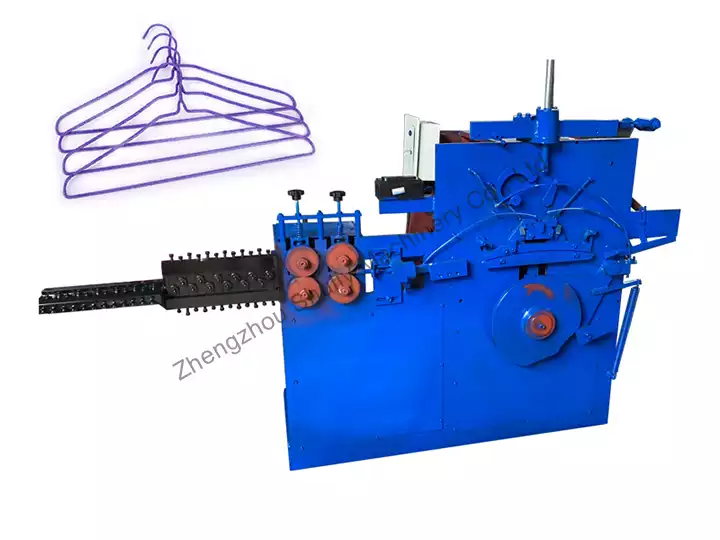

This hanger production line is designed to manufacture various types of hangers with plastic coatings, with a capacity of 30-52 pcs of clothes hangers per minute.

The wire hanger production line commonly uses 1.8-3mm galvanized wires as raw materials to make PVC-coated hangers. This line features high efficiency, excellent automation and customizations.

Also, our hanger machine can meet the global market demand for high-quality and diverse hangers. Thus, it’s widely sold around the world, like Saudi Arabia, Kuwait, Bahrain, India, UAE, and others. If interested, welcome to contact us for more details!

Strength of wire hanger making machine line

- 30-52 pcs of clothes hangers per minute. Our machine realizes automation and continuous production and produces 30-52 hangers per minute. It’s highly efficient.

- Produce curved hook type, ordinary type, butterfly type and other shapes of clothes hangers. According to the different demands of the market, we can produce various clothes hangers.

- Reduce labor costs. The high degree of automation reduces the reliance on manual labor, thereby reducing labor costs.

- Customizable voltage, power, hanger shapes, etc. We can customize these to meet your business needs.

Raw materials for making clothes hangers

The raw materials used to make coat hangers are galvanized wires and plastic wires. For this hanger production line, the galvanized wires are the most suitable.

Clothes hanger manufacturing process

After knowing the raw material, then we’ll introduce the clothes hanger manufacturing process and equipment used in each step.

Step 1: molding

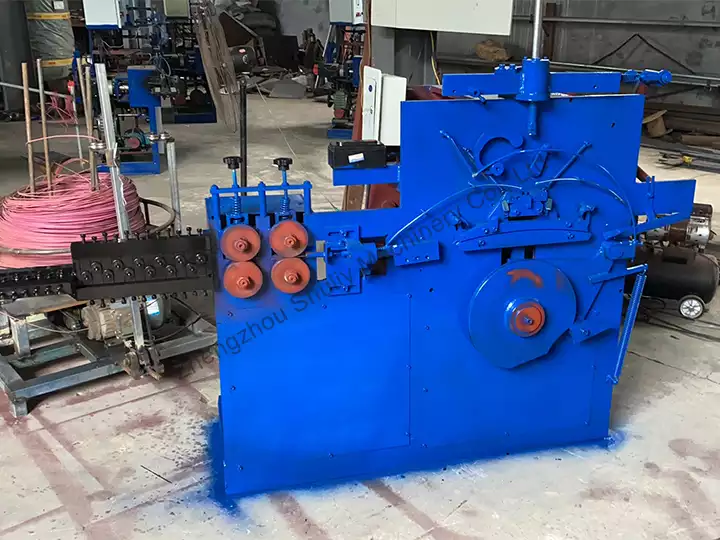

Firstly, feed galvanized wires into a hanger making machine.

This machine bends the wires into the required shapes.

| Machine name | Specifications |

| Hanger machine | Capacity: 30-52pcs/min Hanger size: 11-19inches |

Step 2: powder spraying & collecting

Then, you should spray plastic powder on galvanized wire hangers to enhance the hanger’s durability and appearance.

During the spraying process, the powder is not completely utilized and there is some residue. At this time, the powder collection machine is needed.

Therefore, usually, our powder spraying equipment and recycling equipment are used together, as shown in the figure.

| Machine name | Specifications |

| Spraying machine | Model: DMT-23580 Weight: 25kg |

| Powder recycling machine | Model: PRM-4 Power: 3kw Size: 1.5*1.1*2m |

Step 3: drying

Finally, put sprayed hangers into the drying room.

At high temperatures, the powder cures quickly. It creates a strong surface coating and also ensures the shape and quality of the hanger.

| Machine name | Specifications |

| Oven machine | Model: DMSL-300 Machine size: 3*2.0*1.8m Baking temperature: 180 degrees Baking time: 15-20min/time |

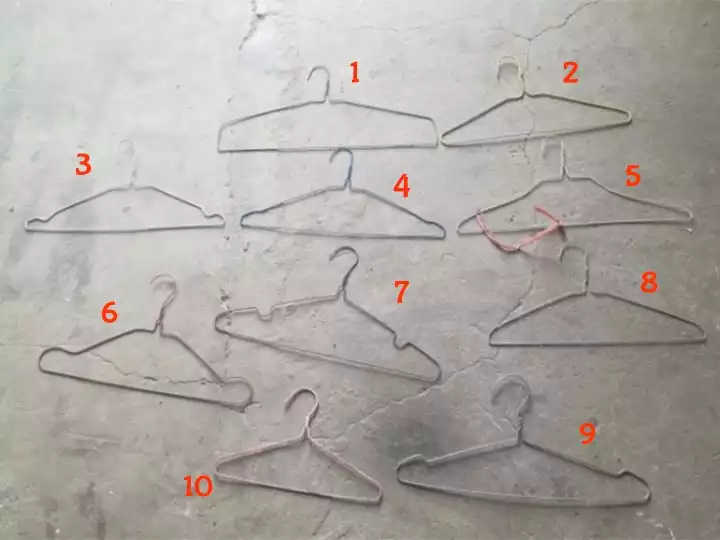

Types of clothes hangers that can be made

Now that we know the hanger manufacturing process, let’s look at the shapes of hangers that can be produced.

There are several types of clothes hangers designed to suit different needs. The most common ones include common-type hangers, butterfly hangers, hook hangers, etc. Details are shown below picture.

Besides, we can customize the hanger shape to meet your demands. If you have any needs, please contact us for more!

What kinds of Shuliy hanger machines are available?

As s professional hanger machine manufacturer and supplier, we have three kinds of hanger machines available. Next, we’ll introduce them in detail.

- Type 1: PLC hanger making machine

- This clothes hanger machine can use two wires. The specific details are shown below:

- Raw materials: 1.8-3mm galvanized wires and 2-4mm PVC-coated wires

- Capacity: 30-45 hangers per minute

- Feature: wide applications

- This clothes hanger machine can use two wires. The specific details are shown below:

- Type 2: wire hanger machine

- This wire hanger making machine only can use galvanized wires.

- Raw materials: 1.8-3mm galvanized wires

- Capacity: 30-45 hangers per minute

- Feature: cost-effectiveness

- This wire hanger making machine only can use galvanized wires.

- Type 3: high-speed clothes hanger machine

- The new-type coat hanger machine is developed according to the market demand and has the following features:

- Raw materials: 1.7-3mm galvanized wires and 2-4mm coated wires

- Capacity: 52 hangers per minute

- Feature: automatic shutdown when hanger with substandard production quality

- The new-type coat hanger machine is developed according to the market demand and has the following features:

How about Shuliy hanger production line price?

The price of a hanger production line varies according to equipment output, production line configuration, after-sales service, etc.

The higher the output, the higher the configuration of the equipment, the higher the price.

Generally speaking, investing in a hanger production line requires comprehensive consideration(production needs and budgets) to select the most suitable equipment. If you want to know more, contact us now!

Global cases of wire hanger machine production line

Globally, the cases of the fully automatic wire hanger production line cover a wide range of countries and regions. These production lines are successfully exported to countries like Saudi Arabia, Oman, Kuwait, UAE, India, Algeria, Jordan, Yemen, Mexico and many more.

The demand for hanger machines is increasing in these countries as hangers are indispensable items in daily life and business.

The following pictures are the loading pictures of our hanger machines exported to these countries, for your reference.

The hanger machine production line plays a key role in meeting the diversified demands of the global market. It improves production efficiency and reduces manufacturing costs. Besides, it also provides a reliable solution to the demand for hangers in different countries.

Get a quote now!

Are you interested in hanger making? If yes, contact us and tell us your requirements, such as capacity, budget, etc. Our professional sales team will provide the best solution!