Shuliy egg tray production line is designed to use waste paper, books, etc. to manufacture paper egg trays to replace traditional plastic packaging. It has a capacity from 1000-8000pcs/h, meeting the needs of different production scales.

The paper tray machine line can produce egg trays, egg cartons, fruit trays, quail egg trays, wine trays, etc. We can also customize the paper tray to meet your demands.

This egg carton production line has features of automatic operation, waste material utilization, flexible production capacity and customizability.

Thus, the egg tray production line equipment has been widely exported to many countries, such as Zambia, Jordan, Cameroon, Senegal, etc.

Features of commercial egg tray production line

- Capacity of 1000-8000pcs/h. This commercial egg tray production line can make paper trays of 1000-8000pcs per hour, which is efficient.

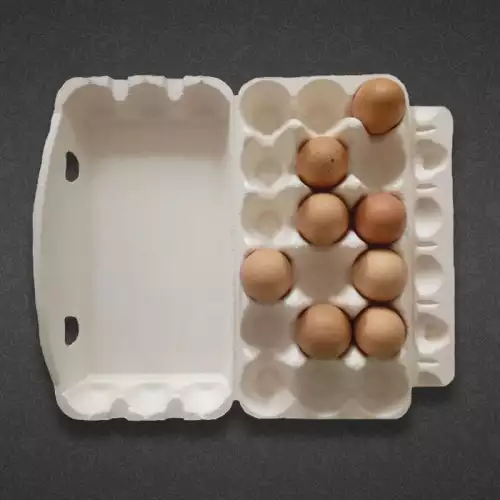

- Making egg trays, egg cartons, fruit trays, etc. Our egg tray making machine can manufacture trays in a variety of shapes and sizes.

- Paper tray shapes: egg tray, egg box, quail egg tray, apple tray, shoe tray, nursery tray, etc.

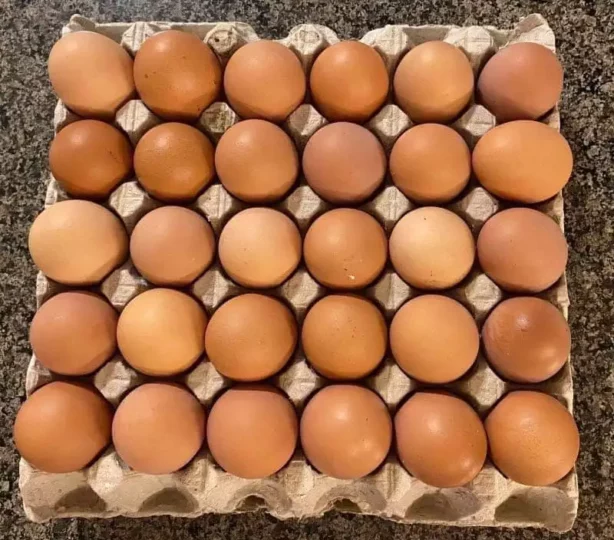

- Paper tray sizes: 30 eggs per tray, 18 eggs per tray, 10 eggs per tray, etc.

- Reduce labor costs. This line is highly automatic, requiring fewer laborers.

- For example, The production line for 1000 pcs of egg trays requires only 1-2 workers to run smoothly.

- Customization. We offer customizable options for branding, labeling, paper tray design, etc.

- After-sales service. Shuliy provides on-site installation and guidance service, 24 hours online to solve problems, etc.

- Low investment costs. Low raw material cost and equipment cost, which enables you to save costs.

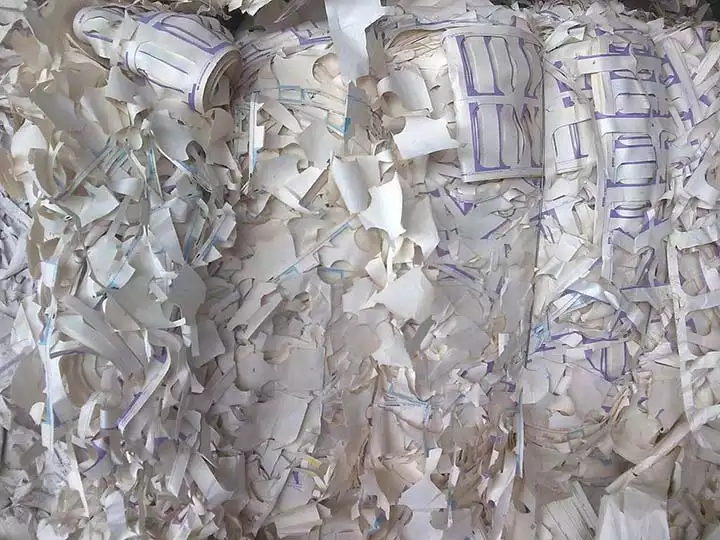

- Raw materials for egg tray making are waste paper, used books, etc. You can get these at a low price. 1 ton of waste paper can produce 12000-15000 egg trays(adjustable according to egg tray weight).

- We’re the factory direct sales. Our equipment has a competitive price in the market.

Raw materials for manufacturing paper trays

The raw materials used in manufacturing paper trays consist of waste paper, newspapers, cardboard, books, magazines, A4 paper, cartons, etc.

Recycling these raw materials to make valuable egg trays helps you turn waste into treasure, making profits.

Egg tray manufacturing process

Knowing the raw materials, now let’s together explore how to make quality egg trays.

Step 1: preparation of raw materials

Firstly, prepare enough waste paper as raw materials. These raw materials usually include paper materials such as old newspapers and waste cardboard.

Step 2: pulp making

Pulp preparation is a crucial step in making egg trays.

Put waste paper and water into the hydro pulper machine. Under the hydro, it makes quality paper pulp.

Step 3: paper tray molding

To make paper egg trays, an egg tray making machine is required. Pour the pulp into an egg tray mold, which is shaped like an egg.

As the pulp is compressed into the desired shape(i.e., the egg tray), excess water is removed.

Step 4: egg tray drying

After moulding, the egg tray should be dried to remove the remaining water.

There are three drying methods for your reference: natural drying, brick kiln drying and drying equipment. Refer to the following information to choose the appropriate method according to your needs.

- Natural drying: this method needs labor’s help. It’s suitable for small-scale egg tray production or start-up, such as 1000-1500pcs/h. It’s most cost-effective.

- Brick kiln drying: it requires brickwork and occupies a large area. We can provide drawings. It’s suitable for medium-sized enterprises, such as 2000-4000pcs/h.

- Egg tray dryer: this requires to purchase an egg tray metal drying machine. It’s suitable for large enterprises with sufficient budget. The egg tray production ranges from 4000-8000pcs/h.

Step 5: hot pressing & packaging

After drying, the trays are hot pressed to give them a cleaner appearance and to ensure consistency. They can then be stacked and packaged ready for dispatch to market.

Finished products of egg tray production line

The finished product of an egg tray processing line is a sturdy and environmentally friendly paper tray designed to hold and transport eggs safely.

These trays are usually of molded design with compartments to hold individual eggs.

In addition, paper tray shapes are customized to meet the specific needs of producers and retailers.

For example, egg cartons, nursery trays, wine trays, potty trays, fruit trays, shoe trays, coffee trays, anisotropic paper trays, etc. If you’re interested, welcome to contact us for more!

Egg tray molds for paper tray production

Egg tray machines can produce various types of paper trays, and molds are the most important. Egg tray moulds are usually made from durable materials such as metal or plastic.

They come in a variety of shapes and sizes. Different molds decide what kind of paper trays are made.

During the egg tray production process, the pulp is poured into these moulds, and excess water is drained. Then the pulp takes the shape of the mould compartment.

After finishing, the paper trays are removed from the moulds to form the final product for egg holding.

Cost analysis of egg tray production line for start-up

To start an egg tray production business, cost analysis is very important. Based on our experience, the following cost analysis of the egg tray production business is available for your reference.

| Item | Details | Cost |

| Raw materials | One ton of waste paper can produce 12000-15000pcs of egg trays(according to the weight of the customer’s finished product) According to the finished egg tray of 80g, one ton of waste paper is 1,000,000g, so one ton of paper can make egg trays of 12,500pcs. Assuming that the price of one ton of waste paper is 1,500RMB, then the cost of each piece of 1,500/12,500=0.12RMB. | Raw material cost per egg tray: 0.12RMB |

| Labour | 6 labors for natural drying and 4 labors for metal drying. Based on the domestic calculation, it’s 0.02RMB per piece. | Labor: 0.02RMB per piece |

| Electric power | According to the output and the power, you can get the cost. Generally, the higher the output, the lower the cost. The average price per piece is 0.02RMB. | Electricity: 0.02RMB per piece |

| Drying | Coal/kg: calorific value 5000 kcal Wood/kg: 4000 kcal Natural gas/m³: 8900 kcal Diesel/liter: 11900 kcal | Coal: 0.03RMB per piece Wood: 0.03RMB per piece Natural gas: 0.06RMB per piece Diesel: 0.08RMB per piece |

| Color | 12RMB per kilogram of pigment. One kilogram can make 3000-4000 egg trays. |

Successful cases of fully automatic egg tray production line

Fully automated egg tray production line success stories demonstrate their efficiency and profitability. These systems enable companies to achieve high yields, reduce labor costs and minimize waste.

Our egg tray production line has been successfully exported to Nigeria, Kenya, Chad, Zambia, Sri Lanka, India, etc. It contributes to sustainable packaging solutions.

There are the loading pictures of our egg tray making machines exported to various countries for your reference.

Get a quote now!

Do you want to make a profit from waste paper? Our egg tray machine can help you! If you are interested, please contact us and we will provide you with the most suitable solution.