Paper pulper machine is used to convert raw materials(waste paper) into pulp, which provides the basis for manufacturing egg trays. It is characterised by high efficiency, environmental friendliness, flexibility and customizability.

This machine makes paper pulp by hydro, which is quick and labor-saving. The role of the hydro pulp machine in the paper tray making process is essential because it’s the 1st step. With its help, you can achieve environmentally friendly packaging solutions.

Role of paper pulper machine in egg tray manufacturing

The pulp machine plays a key role in egg tray manufacturing process. It is responsible for converting raw materials such as waste paper into pulp that can be moulded into egg trays.

This process involves pulping, screening and cleaning the raw material to create a pulp mixture that can be used to make egg trays.

The efficient operation of the hydro paper pulper machine ensures the supply of high-quality pulp for the production of sustainable and environmentally friendly egg trays.

The performance and efficiency of the paper mill pulper machine have a direct impact on the cost and quality of egg tray manufacturing and therefore play a vital role in this production process.

Raw materials for hydraulic pulping

Hydraulic pulping is an important process used in the preparation of paper pulp, the raw materials of which consist mainly of various paper wastes such as old newspapers, discarded cardboard, waste paper and paper cuttings.

Working principle of paper pulper machine

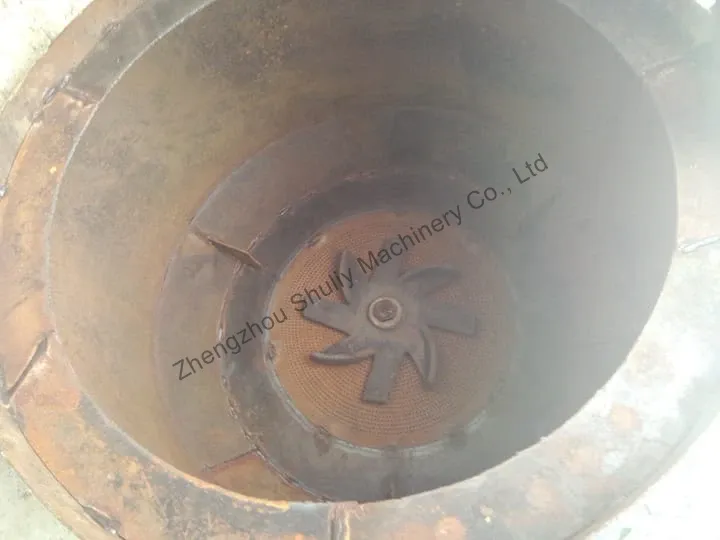

The working principle of paper pulper machine is based on physical mechanics and hydraulic principles. It mixes raw materials, such as waste paper, with water, and then separates and beats the fibres of the raw materials into pulp by mechanical mixing and high-pressure water flow. In this process, the pulp machine will break the fibres in the raw material finely, dispersing them in the water to form a homogeneous pulp mixture.

The key to this process is the mechanical agitation and the pressure of the water, which together contribute to the decomposition of the waste paper and the separation of the fibres, ultimately resulting in pulp that can be used to make a wide range of paper-based products.

How to make paper palp by paper mill pulper machine?

Collection and sorting

Firstly, waste paper is collected and sorted. These raw materials can include waste paper sheets, newspapers, cardboard, used books, etc.

Soaking

The waste paper is soaked in water to soften it and begin to break it down. This is in preparation for further processing.

Pulping

After soaking, the waste paper is fed into a pulper, a key step in the pulping process. In the pulper, the fibres of the pulp are separated and transformed into a pulp-like mixture by mechanical agitation and hydraulic pressure.

Pulp storage

Treated pulp can be stored in special storage facilities for subsequent production of paper-based products.

How do we safely transport paper pulper machine?

When purchasing a pulper for egg tray production, we transport the machine directly to the container or directly to the pulper using a vehicle to ensure that it reaches the customer’s destination.

Of course, we will take certain protective measures, such as fixing the machine, to ensure the safety and integrity of the machine in transit.

Ask about paper pulper machine price!

Want a paper pulp making machine for egg tray making? Come and contact us for more machine details and the best offer!