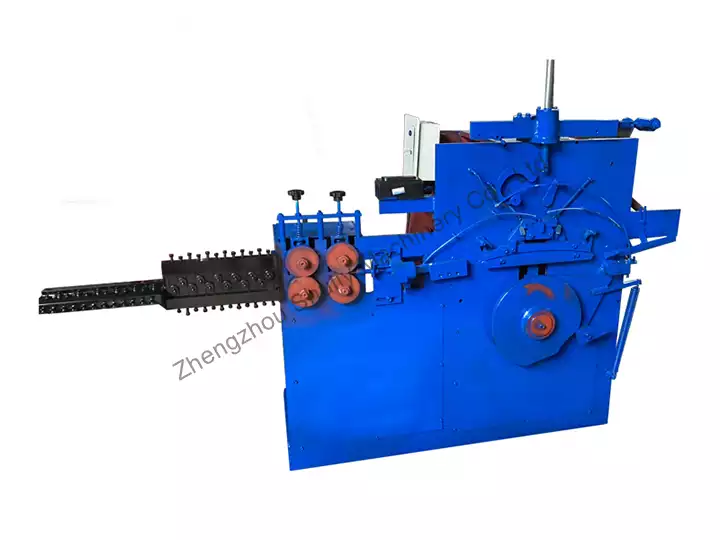

Shuliy hanger machine is used to bend and shape galvanized wires(1.8-3mm) or plastic wires into clothes hangers. Its output ranges from 30-52pcs of hangers per minute.

Our wire hanger making machine is highly efficient, has good performance and long service life. It’s widely used in the clothes hanger manufacturing business.

By changing the machine mold, this hanger machine can produce various types of hangers. Thus, the machines are exported to many countries, including Saudi Arabia, Bahrain, Kuwait, India, UAE, Algeria, etc.

Highlights of Shuliy wire hanger making machine

- Capacity of 30-52 hangers per minute. Shuliy clothes wire hanger machine can produce 30-52pcs of hangers in one minute, highly efficient.

- Various raw materials are available. Raw materials for our machine can be plating lines, iron wires, low carbon wires, galvanized wires, and PVC wires.

- Sheet plate welded structure. The machine adopts this structure to make it run smoothly, and durable.

- Double twists. The upper transmission uses 2 synchronized torsion bars. It’s stable and reliable, with high precision.

- Customizable hanger shape, size, color, etc. We can customize the machine according to different needs, including the shape, size and color of the hangers.

Three Kinds of hanger machines for sale

As a professional hanger machine manufacturer and supplier, we have three kinds of hanger making machines available. Now we’ll introduce them in detail one by one.

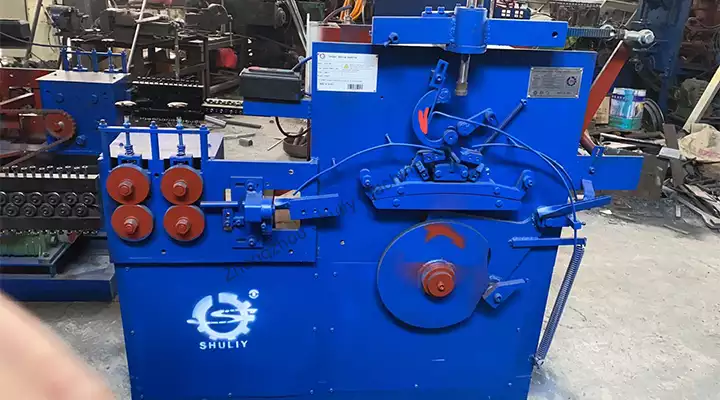

Type 1: wire hanger making machine

This wire hanger machine machine is specially used in making galvanized wire hangers. Also, it can work with other equipment to form a clothes hanger production line for plastic hangers.

- Model: SLPT-400-1

- Capacity: 30-40pcs per minute

- Power: 1.5kw

- Weight: 700kg

- Dimension: 1800*800*1650mm

- Raw materials: galvanized wires of 1.8-3mm

- Hanger type: various types by changing mold

- Hanger size: length of 40cm and height of 20cm(we can customize it)

- Matched equipment(for plastic hangers): spraying machine, powder collection machine, and dryer machine

Type 2: plastic hanger making machine

The coat hanger machine adopts the PLC and automatically controls the hanger production and manufacturing speed.

- Model: SLPT-400-2

- Capacity: 30-42pcs per minute

- Power: 2.2kw

- Weight: 700kg

- Dimension: 1800*800*1650mm

- Raw materials: galvanized wires or PVC-coated wires

- Hanger type: butterfly, common, and others(various shapes by changing mold)

- Hanger size: length of 40cm and height of 20cm(we can customize it)

- Final products: galvanized wire hangers or plastic hangers

Type 3: high-speed hanger machine

This wire hanger making machine is the latest development according to the customer’s production needs. It can be fast production of clothes hangers.

- Model: SLPT-400-3

- Power: 2.2+1.5kw

- Capacity: 52pcs per minute

- Raw material: galvanized wires of 1.7-3.0mm and PVC-coated wires of 2.0-4.0mm

- Machine contact parts: made of hard alloy

- Hanger size: customizable

- Hanger shape: customizable

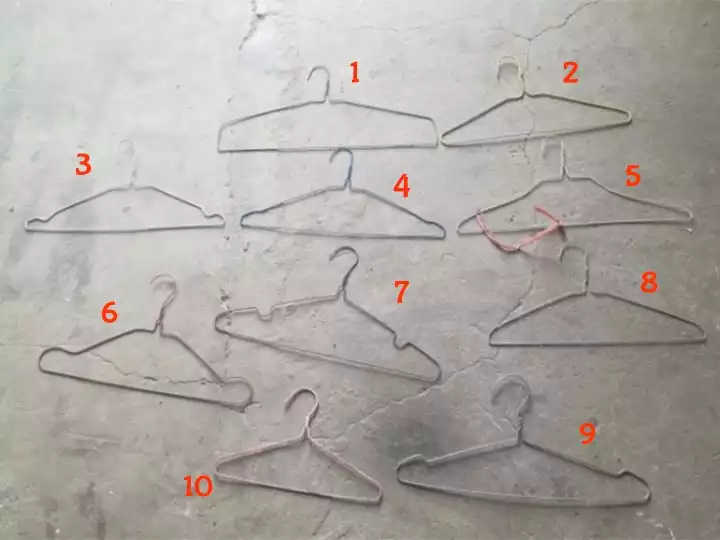

Raw materials and shapes for hanger production

Once you know the types of hanger machines, let’s look at the raw materials used for hanger production and the shapes of the final product.

- Raw materials: plating lines, iron wires, low carbon wires, galvanized wires, and PVC-coated wires

- Shapes: butterfly type, normal type, and customizable shapes(as shown below)

Do you know the hanger manufacturing process?

After knowing the raw materials and shapes for hanger production, next we introduce the manufacturing process of hangers.

Material preparation

Firstly, prepare the raw materials depending on your needs. Raw materials can be galvanized wires or plastic wires.

Feeding raw materials

Then, feed the raw materials to the wire hanger making machine. Generally, we provide the feeding device to facilitate the hanger production. You can decide whether to buy it or not depending on your needs.

Bending and shaping

Next, the wire hanger making machine bends and shapes the wire according to the mold shape, and finally forms the desired hanger.

Discharging and collection

Finally, the hangers are discharged directly and collected.

Tips on choosing the suitable hanger machine from Shuliy

Choosing the right clothes hanger making machine is the key to ensuring production efficiency and product quality. Shuli Machinery offers three types of hanger machines. Based on our experience, we give the following suggestions for your reference when choosing.

- Raw materials

- If your raw material is galvanized wire, then all three of Shuliy’s machines can be used.

- If your raw material is coated wire, then Shuliy’s SLPT-400-2 and SLPT-400-3 are for your choice.

- Capacity

- Our automatic hanger machine has an output ranging from 30-52pcs of hanger.

- If you want 30-40 hangers per minute, then SLPT-400-1 and SLPT-400-2 meet your needs.

- If you want 52 hangers, then SLPT-400-3 is your optimal choice.

- Our automatic hanger machine has an output ranging from 30-52pcs of hanger.

- Budget

- The prices of these three machines, from low to high, are SLPT-400-1, SLPT-400-2, SLPT-400-3. The price starts from $3,000. You can refer to it according to your budget.

- After-sales service

- You may encounter various problems during use, and after-sales service is very important. Our machine price includes after-sales service, which can ensure the smooth operation of the equipment.

The above is for your reference. If you want more professional advice, please feel free to contact us. We will design the optimal solution for you according to your needs.

Successful cases of hanger making machine

Hanger hook making machines have been successfully used in the lifestyle industry. We are often contacted by large garment factories or those who want to start a new business in the field of hanger production.

Also, our hanger forming machines are often exported to Saudi Arabia, UAE, Kosovo, Algeria, Jordan, Mexico and other places. If you are interested, contact us now!

Get a good hanger machine price!

If you want to get a detailed machine price, we suggest you contact a professional supplier, i.e., we, Shuliy Machinery.

We offer the best solutions according to your needs and budget, and you will get cost-effective hanger machines.