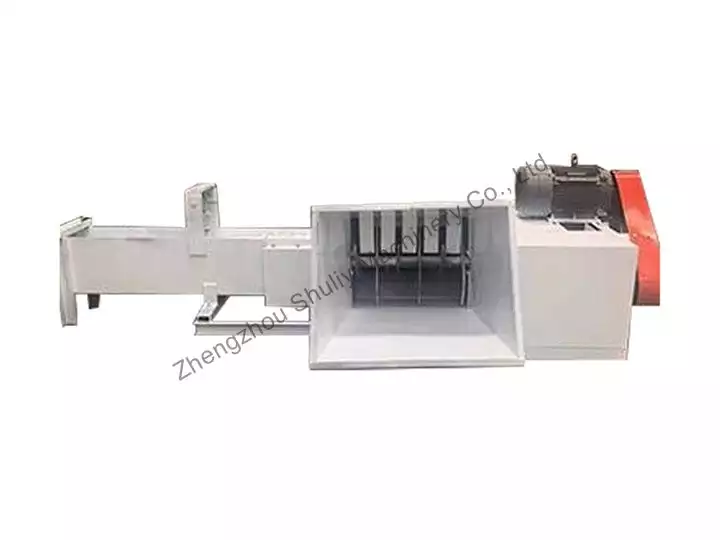

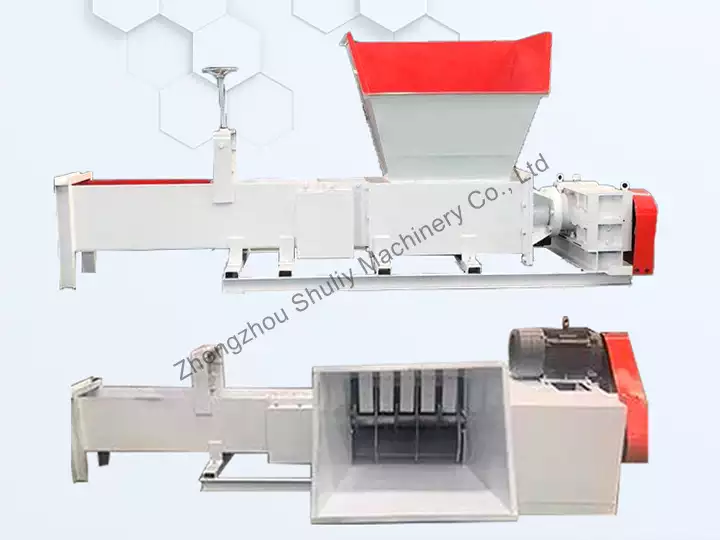

EPS compactor is to compress and compact foam such as polystyrene, EPS foam into regular shapes by low-temperature cold pressing to make profits. It has a handling output of 175-300kg/h.

This Styrofoam compactor crushes and then compresses the foam into blocks for recycling. Compacted foam can be used to produce new foam products like frame products and construction moldings for profit.

Functions of EPS compactor

- Volume reduction: The volume of the foam is significantly reduced after it has been processed in the Styrofoam compactor. This helps to reduce storage and transport costs and alleviates the need for space during processing.

- Increase in density: EPS foam cold pressing styrofoam densifier compresses the foam by applying pressure, increasing its density. This makes the foam stronger and more suitable for more applications.

- Improve quality: The compressed foam is more compact and has a more uniform texture. This helps to improve the quality and performance of the product.

- Recycling and recovery: Compressed foam can be more easily recovered and reclaimed for use in the manufacture of new foam products, recycling resources and reducing the burden on the environment.

Technical data of EPS compactor for sale

Our EPS foam densifier has different models available for projects of different sizes and capacities, depending on project requirements and budget. Below are the detailed machine parameters for your reference.

Model: SL-300

Capacity: 175kg/h

Power: 15kw

Inlet size: 830*760mm

Machine size: 3000*1700*900mm

Model: SL-400

Capacity: 300kg/h

Power: 22kw

Inlet size: 870*860mm

Machine size: 4600*2800*1200mm

Do you know EPS cold compactor features?

- Cold pressing process in a few tens of seconds: EPS foam compactor compresses loose EPS foam into high-density block material, reducing volume, storage and transport costs.

- Intelligent control system: It allows for automatic operation and highly customized settings to improve ease of operation.

- Low-temperature cold pressing: This technology reduces energy consumption and environmental pollution, and promotes the recovery and regeneration of discarded EPS foam.

- Customizable feeding sizes: Different feeding sizes are available to fit your needs.

Why use EPS foam compactor for recycling?

Foam is widely used in the packaging industry, large volume and high transport costs.

This polystyrene recycling equipment can compress the large volume, messy foam into high-density, regular shapes. It makes the transport convenient and reduces the transport cost, and improves the working rate for the customers.

What foam can be recycled by Styrofoam compactor?

Styrofoam compactor can typically recycle various types of foam, including Expanded Polystyrene (EPS) foam commonly known as Styrofoam, Polyethylene (PE) foam, Polypropylene (PP) foam, Extruded Polystyrene (XPS) foam, and Expanded Polypropylene (EPP) foam.

How about Shuliy EPS compactor price?

Styrofoam densifier prices vary by model, specification, manufacturer and market area. As a professional manufacturer and supplier, we provide the EPS foam compactor at a competitive price.

We’re integrated with producing and trading, so our machine not only has the good quality, but also has a good price, compared to other suppliers.

If you want a recycling machine for foam, just contact us for more details to facilitate your recycling business!

Related foram recycling machines from Shuliy

For foam recycling, in addition to the EPS compactor, we also have foam crusher and foam hot melting machine that can be processed for all kinds of foam materials. Please refer to the following: