EPS foam pelletizing machine is specialized in processing waste foam such as EPS EPE into foam pellets. These recycled foam granules can be reused for the production of new foam products, realizing the resourceful recycling of foam waste.

Of course, we also have granulator for EPE foam, the same function as the EPS foam recycling machine. Thus, we have two kinds of foam pelletizers for sale. This machine is essential in the foam recycling line. If you’re interested, welcome to contact us for more machine details!

Types of foam granulators

As a professional recycling machine manufacturer and supplier, we have two foam pelletizing machines for sale. Each foam pelletizing machine targets specialized foams. Learn more about it below.

EPS pelletizing machine

This equipment is mainly for EPS foam, including but not limited to Styrofoam boxes, foam board protection mats, civil engineering roadbed filler, etc. This type of foam waste is recycled and then processed twice to form consistent recycled pellets, which create profit value for the recycling plant again.

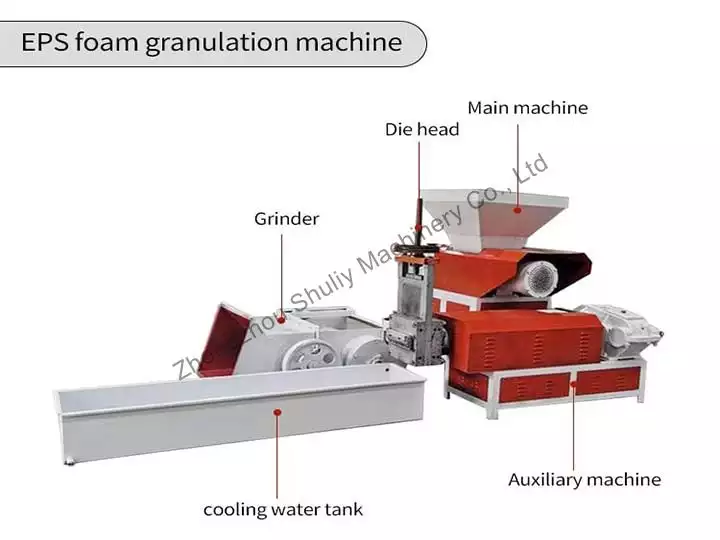

Structural components of EPS foam pelletizer

To be honest, this EPS foam pelletizing machine has been designed with your usage in mind, and therefore the composition is very simple. Its structure includes main machine, die head, cooling tank, grinder and auxiliary machine. When you operate the machine, it’s easy to understand and use, which is user-friendly.

Technical data of EPS foam pelletizing machine

Model: 220+150

Power:15kw+5.5kw

Capacity:150-200kg/h

Double reducer

Electric mould as picture(change net without stopping machine)

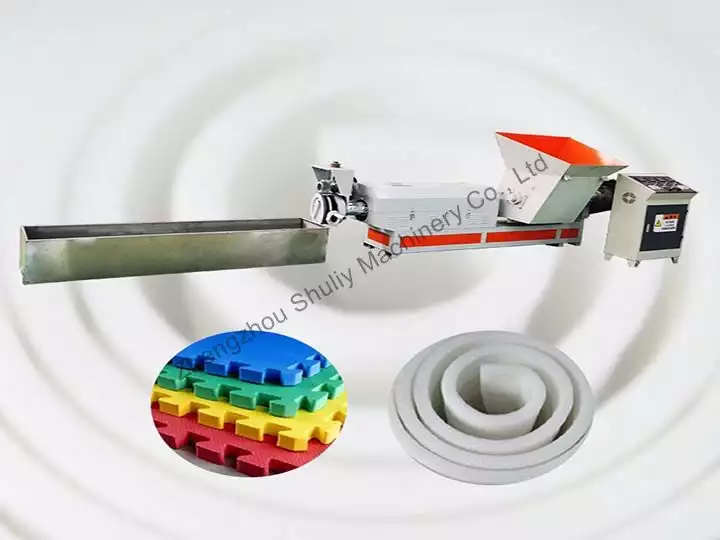

EPE Styrofoam pelletizing machine

Compared with EPS foam granulator, the main foam material for this machine is EPE pearl cotton. As you can see from the appearance, this machine is still different from the EPS pelletizing machine. If you want to do pearl cotton treatment, this machine is your good choice.

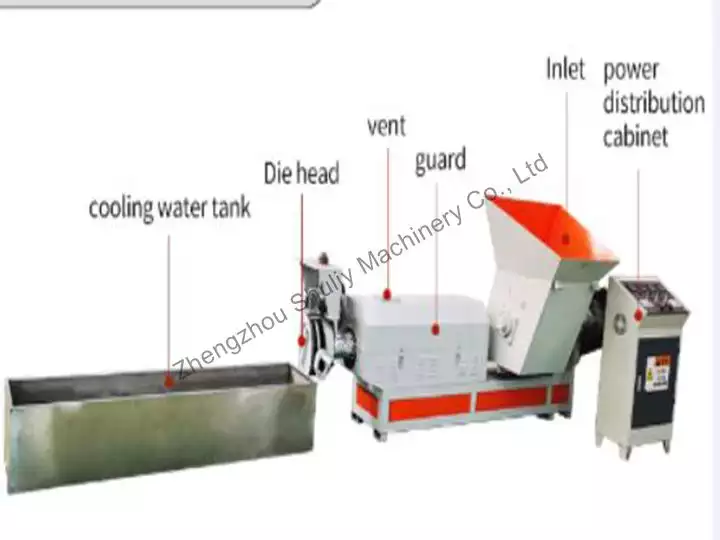

What consists of EPE foam making machine?

Its structure is straightforward, with the control cabinet, inlet, fan, cover, die head and cooling water tank. From its construction, you can get that this machine is easy to operate.

Technical data of EPE foam granulator

Model: SL-160

Machine size:3400*2100*1600mm

Inlet size:780*780mm

Power:30kw

Capacity:150-200kg/hour

Heating method: heating ring

Machine features of EPS granulator

- Different foam with different melting points and different screw ratios: Adjustment to different foam characteristics, including melting point and screw ratio, ensures optimal production results.

- Easy input and high output: Designed to focus on ease of operation, it can easily put in EPS raw materials, while ensuring high output production and improving production efficiency.

- Stable machine performance and easy operation: Adopting advanced control system to ensure stable machine operation. The user-friendly interface and simplified operation process make the operation more convenient.

- Crushing and pelletizing: The EPS foam pelletizing machine first crushes and then granulates to achieve efficient recycling of waste EPS.

- Multi-purpose use of recycled foam pellets: Produced granules can be widely used to make plastic bags, buckets, building accessories, etc., giving new life to the waste EPS material.

How can foam materials be extruded?

Preparation of raw materials

Firstly, plastic foam is fed into the production line as raw material. This is usually waste foam material.

Heating and melting

The raw material passed through a heating system, usually a screw extruder. Here, the raw material is heated to a temperature high enough to melt.

Pressure extrusion

Melted plastic foam is pushed out by the pressure in the screw extruder. This is achieved by pushing the melted plastic through the movement of the screw and barrel.

Shape forming

The extruded melt is passed through a mould or die to be formed to the desired shape and size. This can be in the form of tubes, films, rods etc.

Cooling and curing

Moulded materials are passed through a cooling system, e.g. water cooling, to allow it to cure and maintain the desired shape.

Cutting and collection

Finally, the plastic foam material that has been moulded may need to be cut or slit to obtain the desired length or shape. Afterwards, these products are collected for packaging or further processing.

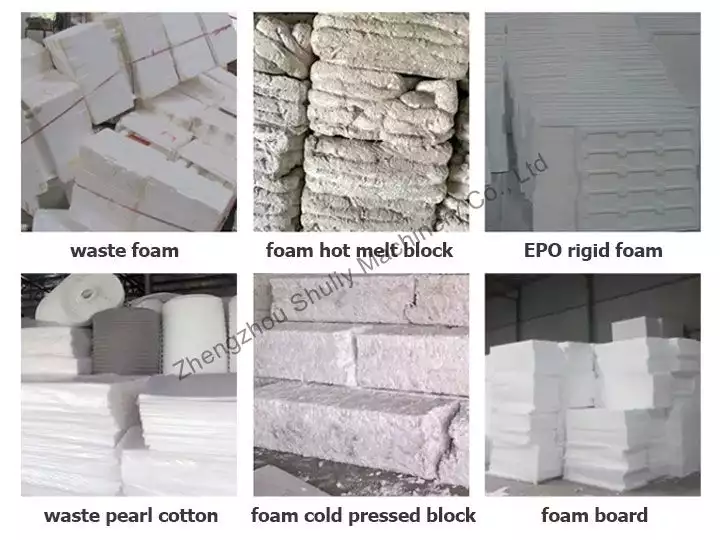

Applications of EPS foam pelletizing machine for sale

PS polystyrene foam sheet plastic extruder is widely used for recycling and processing various foam materials, including waste foam, foam hot melt blocks, EPO rigid foam, waste pearl cotton, foam cold press blocks, and foam boards.

The machine gives a new life cycle to these waste foam materials by crushing and recreating them into high-quality pellets through efficient processing technology.

Tips to choose a suitable EPS foam recycling machine

- Processing capacity: Select the processing capacity of the machine according to the actual demand to ensure that it can meet the processing demand in the working scenario to improve efficiency.

- Process flow: Different EPS foam recycling machines may use different process flows, including crushing, melting, extruding and other steps. Choose a suitable process according to the nature and requirements of the waste foam.

- Machine quality: Choose a reputable manufacturer with excellent quality to ensure the stability and durability of the selected EPS foam pelletizing machine to reduce maintenance costs and extend service life.

- Energy consumption and environmental protection: Consider the energy consumption and environmental performance of the machine, and choose an EPS foam pelletizing machine that meets energy efficiency standards and is environmentally friendly.

- Maintenance and after-sales service: Choose a manufacturer that provides comprehensive after-sales service to ensure timely support and maintenance during use.

- Cost-effectiveness: Considering the investment cost and operation cost, choose the EPE EPS foam pelletizing machine that best meets the actual demand and has high cost-effectiveness.

Related equipment for EPS foam recycling

As a professional EPS foam pelletizing machine manufacturer and supplier, we have a series of recycling machines available, such as EPS foam crusher, hot melting machine and foam cold press. If want to learn more, please read below for your reference.

Inquiry about EPS foam pelletizing machine price!

Do you want EPS foam pelletizing machine for waste foam recycling? If so, contact us and we will design an optimal solution for you as well as