Plastic pelletizing machine is designed to process plastic soft materials into pellets for reuse or sale, such as PP, LDPE, woven bags, etc. Our plastic recycling pellet machine has the advantage of high performance, good quality and cost-effectiveness.

Besides, our machine can also process rigid plastic materials. It has a handling capacity of 3000kg-7000kg per 24 hours. Thus, our plastic pellet making machine is very popular in countries, such as Kenya, Nigeria, etc. If you’re interested, welcome to contact us at any time!

Plastic films to be processed

- LDPE: Typically used in plastic bags, film, etc. and can be recycled.

- LLDPE: Commonly used in plastic packaging film and has recycling potential.

- PP: Used in the manufacture of bottles, boxes, industrial fibres, etc., and can be recycled through recycling.

These soft plastics can be reused in the recycling process through appropriate treatment and regeneration techniques, helping to reduce the need for new plastics.

Advantages of Shuliy plastic pelletizer

- Excellent performance: Efficiently crush, melt, extrude and granulate waste plastics.

- High-quality materials manufacturing: Sturdy and durable, low failure rate and long service life.

- High cost performance: Reduce production costs, maintenance costs, and operating costs, and provide high-quality after-sales service.

Technical parameters of plastic pelletizing machine

For your easy choice, please refer to “https://recyclemachine.org/plastic-granulator-machine/#Optional_models_of_plastic_recycling_granulator“

If you want to start a plastic recycling plant for the first time, then we would recommend that you start with a small-capacity plastic granulator, and the SL-125 model is your best choice.

Whether you are a beginner or want to expand your output, our plastic pelletizing machine can meet you, tell us your needs, and we will provide you with the optimal solution.

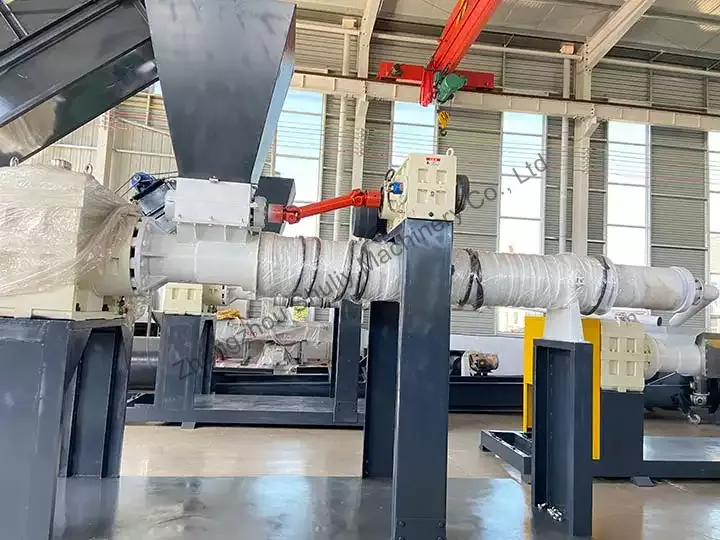

Components of plastic film pelletizing machine for sale

These below components work together to complete the entire production process from waste plastic film to recycled pellets.

| Machine components | Function |

| Feeding | Introduces waste plastic film inside the machine, ready for subsequent processing |

| Melting | Melts the crushed plastic film by heating it to make it plasticize and provide raw material for subsequent extrusion |

| Extrusion | Extrudes the melted plastic through the extrusion mechanism to form continuous granular materials |

| Cooling | Cooling of the extruded pellets to solidify them into a granular state. |

| Cutting | The cooled pellets are cut into the required lengths, resulting in recycled plastic pellets of uniform specifications. |

Three types of moulds for plastic pellets extrusion

Our plastic pelleting machine is usually equipped with three different types of die heads to meet the different needs of the customer. These three types of die heads can be used to produce a wide range of products, such as plastic pellets of a certain size, granules of a uniform length and pellets with a smooth surface. The type of mould to be used with your plastic pellet maker depends on your needs.

Role of plastic pelletizer machine in plastic film granulating line

The plastic pelletizing machine plays a key role in PP PE film pelletizing line. Its main task is to process the waste plastic film through the process of melting, extruding and other processes, and finally form uniform specification of recycled plastic granules.

Through the action of the plastic pelletizer, the waste plastic film can be effectively utilized, realizing the recycling of resources, reducing the burden on the environment and promoting sustainable development. Its efficient granulation process provides a viable and economical solution for plastic recycling.

How about the plastic pelletizing machine price?

The plastic pelletizer machine price is affected by a number of factors, including machine specifications, capacity, raw materials, plastic pelletizing process, and the brand reputation of the manufacturer.

The price of plastic pellet maker varies greatly with different specifications and configurations.

Regarding Shuliy’s plastic pelletizing machines, the price advantage is reflected in many aspects.

- Firstly, as a manufacturer with rich manufacturing experience and expertise, Shuliy is able to provide high-quality plastic pellet making machines.

- Secondly, the price of our plastic pelletizing machine is more reasonable compared to competitors, which have certain market competitiveness.

- In addition, Shuliy focuses on after-sales service, provides all-around support, solves problems in production for customers, and improves the stability and reliability of the equipment.

Overall, the plastic pelletizing machine price is competitive and known for its high cost performance, so that you get a better return on investment when purchasing the equipment.

Package and delivery of plastic pellet making machine

When carrying out the plastic pelletizing recycling machine in the packing and transporting process, we use professional packing materials, such as wooden crates and protective films, to ensure the safety of the machine during the delivery process.

Export standards are strictly followed to ensure that the pelletizing machine for plastic recycling reaches customers in perfect condition to provide the best possible experience.

Get in touch with us for more machine details!

If want efficient plastic recycling, contact us for more detailed information about plastic pelletizing machines! Whether you are recycling plastics or need a customized solution, we offer professional support and consulting services.