Shuliy plastic shredder machine is mainly to crush soft and rigid plastic materials(like PP, PE, LDPE, HDPE and PET) into small pieces for recycling. It has an output of 400-1200kg/h.

This plastic crusher machine can be powered by an electric motor or a diesel engine. The screen size used to crush different plastics is different. It’s about 26mm for film and 50mm for hard materials.

The machine has features of wide applications, high efficiency and good quality. It’s commonly used in the plastic recycling line.

Our machines have been exported to Oman, Nigeria, Ethiopia, Ghana, etc. If you’re interested, welcome to contact us for more details!

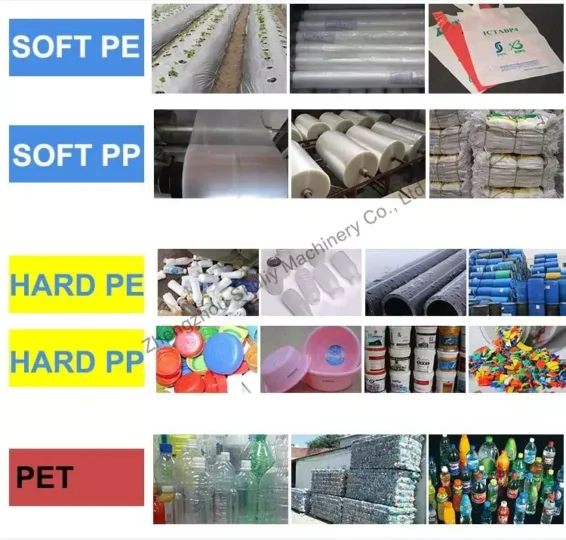

Materials crushed by plastic shredder machine

Shuliy plastic shredding machine can pulverize many kinds of plastic wastes, like PP, PE, LDPE, HDPE and so on. The specific materials are as follows:

Agricultural film, film bags, cling film, foam, rigid plastic, plastic boxes, food containers, polyethylene, polypropylene, polyvinyl chloride, polystyrene, polycarbonate, polyamide, PET bottles, HDPE bottles, PVC pipes, PC sheets, ABS parts, plastic toys, plastic drums, etc.

Advantages of plastic shredder machine in plastic recycling

- Capacity ranging from 400-1200kg/h. Our plastic crusher machine is highly efficient, and can shred plastic waste of 400-1200kg per hour.

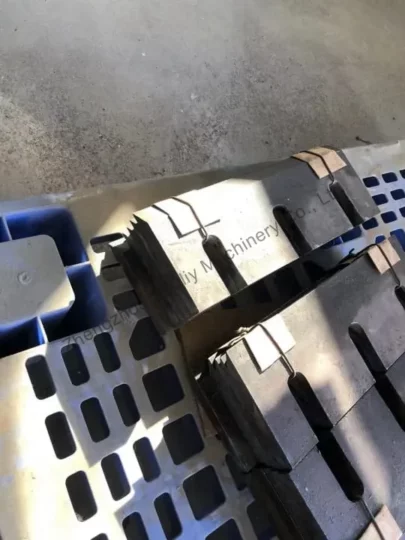

- Blade made of 60Si2Mn or 5Sicr. The machine blade adopts 60Si2Mn or 5Sicr, which is wear-resistant and has a long service life.

- About 26mm screen size for film and 50mm for hard materials. This industrial crusher matches different screen sizes for soft and rigid plastic materials shredding.

- PP PE LDPE HDPE crushing. Shuliy industrial plastic shredder has a wide range of applications, such as trash bags, membranes, pipes, shampoo bottles, etc.

- Customization. We can customize the power, voltage, blade material, etc. to meet your needs.

Technical parameters of plastic shredder machine

| Model | SL-400 | SL-600 | SL-800 | SL-1000 |

| Capacity | 400-600kg/h | 600-800kg/h | 800-1000kg/h | 1000-1200kg/h |

| Blade width | 100cm | 600cm | 800cm | 1000cm |

| Blade qty | 10pcs | 10pcs | 10pcs | 10pcs |

| Blade material | 55Crsi | 60Si2Mn | 60Si2Mn | 60Si2Mn |

| Power | 11kw | 22kw | 45kw | 55kw |

We have 4 types of plastic shredders for sale, respectively SL-400, SL-600, SL-800 and SL-1000. The crushing capacity is 400-1200kg/h. It can suit plastic recycling lines with different outputs.

The above parameters are for your reference when choosing a suitable plastic recycling shredder. If you have questions, contact Shuliy Machinery for more information and advice.

Structure of plastic shredder machine for recycling

This machine consists of inlet, outlet, electric motor or diesel engine, blades and screens, screw converyor, etc.

How to crush waste plastic?

Feeding

Feed plastic materials to the inlet of the commercial plastic shredder machine. You can send materials by the screw conveyor.

Shredding

Once the plastic materials enter the plastic film shredder, the blade system begins to rotate and cut, tear and break them. The movement and force of the blades break them into smaller particles.

Screening

After crushing, the plastic particles are screened through a screen. You can adjust the screen size to achieve the desired size.

Discharging

The plastic pieces are discharged by “U” type conveying.

Waste plastic shredder machine role in the plastic recycling line

In the plastic recycling line for pelletizing, the main steps include crushing→washing→granulation. Thus, the machine is the first step for the PP PE granulation line.

In the PET bottle recycling line, the main steps include label removing→crushing→washing→drying. It’s the core part of this line.

Do you know the cost of plastic crusher machine?

Plastic shredder machine prices can vary widely depending on factors such as its capacity, features, brand, and where you buy it. Prices may change over time and may vary by region and supplier.

To get accurate and up-to-date prices for plastic shredders, we recommend contacting us directly for the latest pricing information.

Services provided by Shuliy about plastic recycling machines

Shuliy is a renowned manufacturer in the field of plastic recycling machines and offers a range of services related to plastic recycling. These services may include:

- Supplying high-quality plastic recycling machinery: such as plastic shredder machine, PET bottle crusher, plastic granulator, etc.

- Providing technical support: machine manual, installation video and others.

- Offering after-sales services: on-site installation and guidance, 24-hour online service, timely response, etc.

Where to find a good plastic shredder machine manufacturer?

There are several ways to find reliable plastic shredder manufacturers. These include:

- Searching online

- Checking industry reputation

- Seeking expert advice

- Checking supplier directories

By combining these methods, you can identify manufacturers that are known for their quality products and meet your specific requirements.

Shuliy not only ranks high in Google searches, but also has a good reputation in the field of plastic recycling. We also have factories and experienced expert services. If you’re looking for a reputable manufacturer, we are exactly what you are looking for.

FAQ of plastic shredding machine

What is the water consumption per hour of a 1000kg/h crusher?

1 to 2 tons of water.

What is the role of injecting water into the plastic crusher when crushing film materials?

1. Wet the film material to make it easier to enter the shredder.

2. Reduce the friction heat of the blade and increase the service life.

3. Preliminarily rinse the material (rough washing).

What are the benefits of U-type conveying(conveying materials after crushing)?

It is convenient to open the cover. When the film material is blocked or hung, it can be opened at any time. And it is easy to maintain.