Plastic pelletizing line is recycling PP, PE, PS, ABS, PA, PVC, PC, POM, EVA, LCP, PET, PMMA, etc for plastic granule making with high efficiency, good performance and cost-effectiveness.

It’s an automatic assembly line from washing and crushing to granulation, having a capacity of 150kg, 200kg, 300kg, 500kg, 1000kg, 2000kg and others.

Because of the different raw materials for granulation, we also separate PP PE film washing recycling line and PP PE plastic flakes pelletizing line. Due to its strong application, this plastic recycling line is very popular in Ethiopia, Mozambique, Ghana, Nigeria and other countries.

Video on how to turn plastic films into pellets

Raw materials for PP PE PVC plastic granules making

For the plastic recycling line, raw materials for the manufacture of plastic pellets include waste plastic products such as:

Plastic tubs, footbaths, buckets, plastic chairs and stools, plastic bags, trash bags, woven bags, baling strips, PP juice bottles, shampoo bottles, agricultural films, food packaging films, greenhouse films, empty containers, tubes, packaging strips, ropes and cables, fishnets and woven fibres, as well as types of plastics including PP (polypropylene) and PE (polyethylene).

How about plastic pelletizing process?

Crushing

Firstly, the waste plastic products are processed through a plastic crusher machine to be chipped into small particles to provide better processing conditions for the subsequent steps.

Washing and cleaning

The crushed plastic is cleaned through a washing system to remove surface contaminants, grease and other impurities to ensure the quality of the crushed plastic.

Drying

Cleaned plastic is processed through a dryer to remove moisture and ensure that the pellets are not exposed to moisture during subsequent processing.

Pelletizing

Dried plastic is pelletized through a pelletizing machine, where small particles are heated, melted and extruded to form filaments.

Cooling

The filamentary plastic granules are passed through a cooling system that cools and cures the granules to ensure their shape and quality.

Pellets cutting

Cooled plastic pellets are cut by a pellet cutting machine to achieve the required length and shape and to improve the uniformity of the pellets.

Storage and bagging

Finally, the plastic pellets are stored and packaged as required for transport and sale.

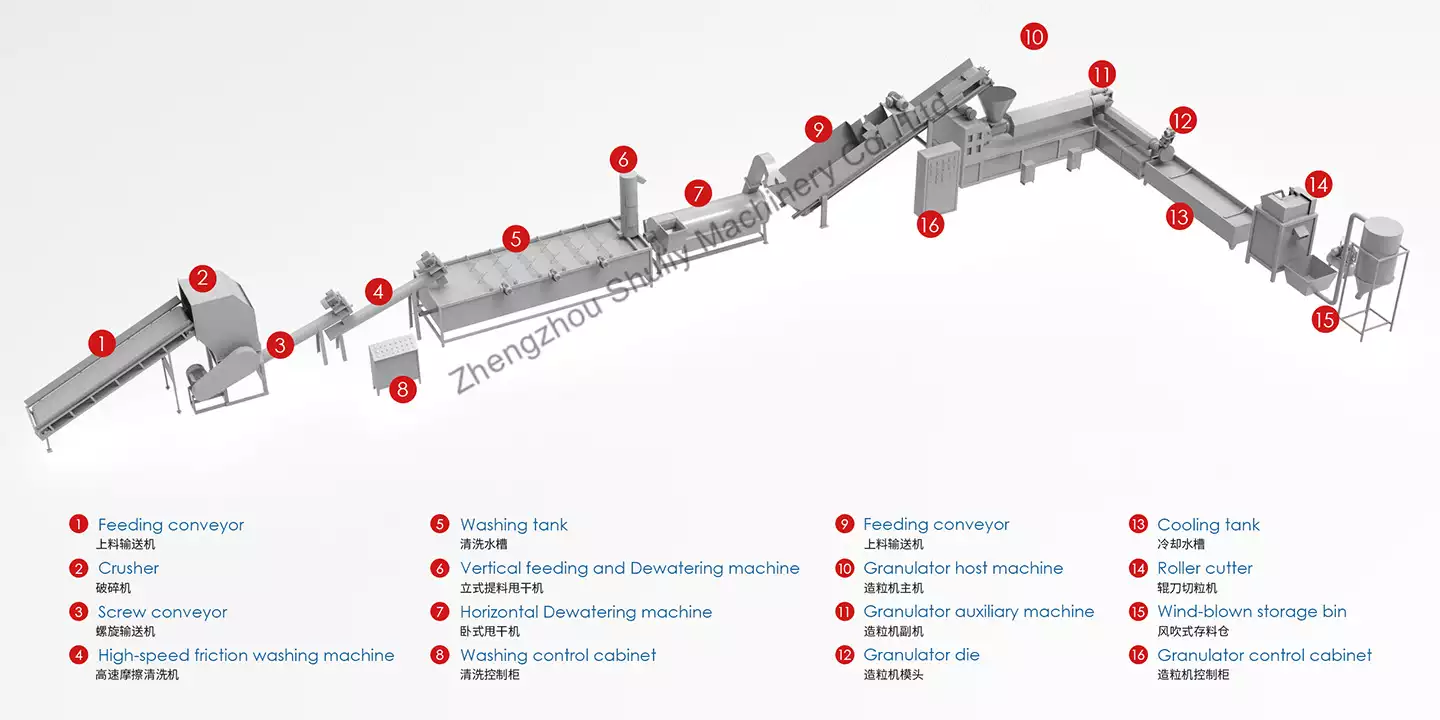

Plastic recycling machines used for plastic pelletizing line

Feeding conveyor

Send waste plastics to the plastic crusher machine

| Item | Specifications |

| Conveyor | Power:3kw Length: 5m Width: 0.8m Capacity:1000-1200kg/h |

Crush of all kinds of waste plasticized plastic products as raw material for production

| Item | Specifications |

| Plastic shredder | Model:1SL-000 Power: 37kw+11kw Capacity: 1000kg/h |

Washing tank

Rink crushed raw material in the sink, and the film material is often cleaned with a pickle wheel because it is soft.

| Item | Specifications |

| Plastic film washer | Model: SL-500 Capacity: 100-500kg/h Power: 2.2kw Length: 5m, 10m, 15m, 20m(length can be customized) |

Dry the cleaned raw materials in preparation for pelletizing

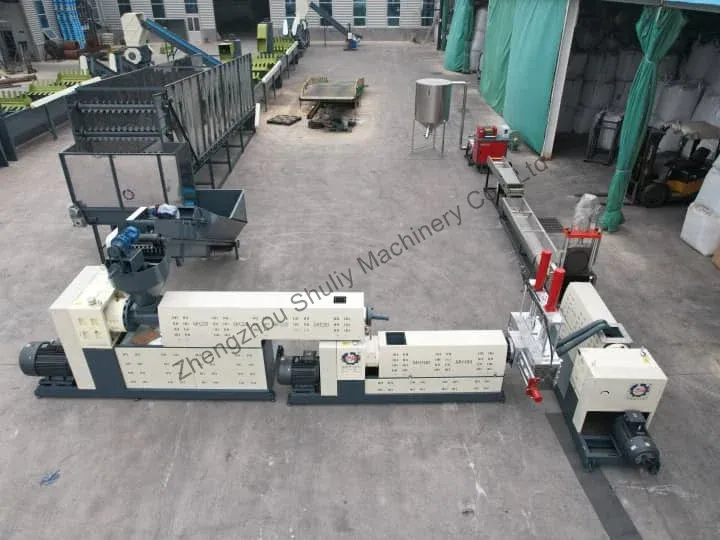

This process usually prepares two machines, one main machine and one auxiliary machine, to heat and melt the waste plastics and extrude them into pellets.

| Item | Specifications |

| Main plastic pelletizer Auxiliary plastic granulator | Model: SL-260 Screw diameter: 260mm Screw length:3.6m Motor: 110kw Model: SL-220 Screw diameter: 220mm Screw length: L1.6m Motor:22+18.5kw |

Cooling tank

Threading plastic pellets come from the auxiliary machine and into this cooling tank to shape.

Plastic pellet cutting machine

Cut the cooled plastic threads into granules

| Item | Data |

| Pellet cutter | Model: SL-300 Power:7.5kw Capacity: 800kg/h |

Storage bin

Storage of uniformly sized plastic pellets for the next stage of processing

Bagging machine

Bagging of plastic pellets for sale

| Item | Data |

| Bagging machine | Power:1.5kw Dimension: 1000*1200*1100mm Weight: 120kg |

Working principle of rigid plastics and PP PE film recycling line

The working principle of the plastic pelletizing line is very simple, mainly plastic granulator, which adopts the process of high-temperature melting, plasticizing and extruding to change the physical properties of the plastic to achieve the plasticizing and moulding of the plastic.

Difference between plastic film and plastic flakes pelletizing lines

For different plastic materials recycling, the configuration of PP PE plastic pelletizing line is a little bit different. The main difference is shown below:

In the PP PE film washing recycling line, add the forced feeder on the plastic granulator.

In the PP PE flake recycling line, after vertical lifting material, the horizontal dryer follows.

Features of plastic pelletizing line for sale

- Efficient production: This PP PE plastic pelletizing line adopts an advanced production process, which can efficiently convert waste plastic products into pellets and improve production efficiency.

- Fully automated operation: The plastic film recycling washing line uses an advanced automated control system, which reduces manual intervention and improves operation convenience and production consistency.

- Multi-functional processing: Suitable for different types and shapes of waste plastics, with strong applicability, and can process a wide range of materials such as hard plastics and soft plastics.

- Environmental protection and energy saving: During the plastic pellets production process, the equipment adopts environmental protection technology, effectively reducing energy consumption, in line with the green production concept.

- Stable pellet quality: The plastic recycling granulating line can maintain the consistency and high quality of pellets during the extrusion and cutting process, which can meet the needs of different applications.

- Low-noise environment: Low-noise design reduces noise pollution in the production process and improves the comfort of the working environment.

How about plastic recycling pelletizing line price?

The price of plastic palletizing line is affected by many factors, such as the production scale, the configuration of the production line, different suppliers and so on. The price varies between tens of thousands and more than one hundred thousand US dollars.

As a professional plastic recycling producer and fabricator, we will explain you in detail.

For example, if you are going to do plastic film recycling, the plastic pelletizing line equipment you can choose includes conveyor, crusher, PP HDPE film washer, dryer, forced feeder, granulator (main machine and auxiliary machine), cooling tank, granule cutter, storage bin, bagging machine.

Among them, depending on the output, the granulator model you choose is different, and the price difference is large. In addition, the storage bin and bagging machine can be replaced or manually completed, whose price also varies.

Therefore, if you want to really know what is the price of the plastic recycling granulating line, come to contact us. Our professional staff will recommend the right equipment and offer the best quotation for you according to your needs.

Why choose Shuliy as PP PE plastic pelletizing line supplier?

- Expertise: Shuliy has extensive experience in the plastics recycling and processing industry and is committed to providing efficient and reliable solutions.

- Customized services: Depending on the needs of our customers, we’re able to provide customized services to meet the processing requirements of different types of waste plastics.

- After-sales service: Shuliy provides comprehensive after-sales service, including equipment installation and commissioning, training, maintenance and technical support, to ensure customers’ normal production operations.

- Quality assurance: All our plastic pelletizing lines are subject to strict quality control and testing to ensure the stability and durability of the equipment.

- Global customer base: Our products are sold worldwide and have established a good reputation in the international market and are recognized by many customers.

- Comprehensive solutions: We provide not only single equipment, but also total solutions, including front-end waste plastics processing, pelletizing lines and back-end packaging, providing customers with one-stop services.

Safety checks before using PP PE plastic granulation line

- Arrange the equipment, check the screws and tighten all screws.

- Wiring: connect all motor wires, heating wires, electromagnetic heating wires, granulator wires according to the marking of the control cabinet.

- Add water: The cooling water tank is filled with water. Build your own water circulation cooling system if necessary.

- Check the switch of each electrical part, run the motor to check the forward and reverse respectively, the oil level of the gearbox, and the lubrication of the rotating parts.

- Check the fastening of each part, check whether the electricity and water supply is normal, whether the lines and pipelines are well connected.

Get a quote now!

Are you interested in plastic recycling for profit? If so, contact us and our professional manager will provide you with the optimal solution for your needs.