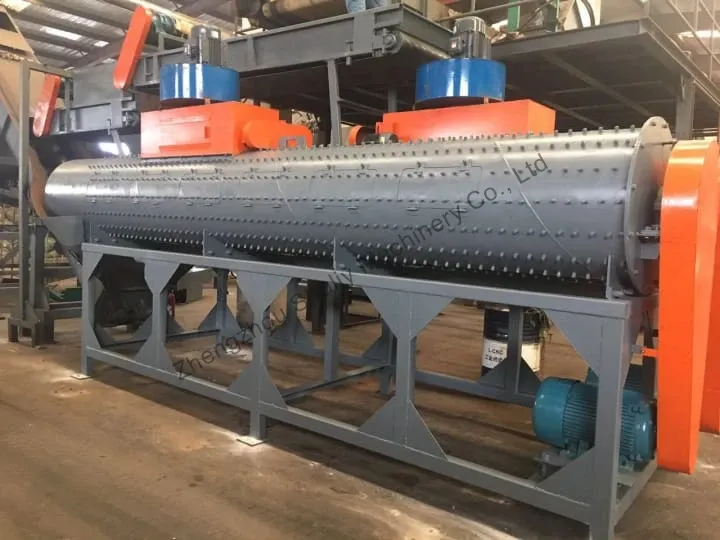

Shuliy PET şişe etiket sökücü makinesi, tüm plastik şişelerin (veya düzleştirilmiş şişelerin) dış etiketlerini verimli bir şekilde soymak için tasarlanmıştır. Etiket sökme oranı >'dir.

Bu plastik etiket çıkarma makinesinin kapasitesi 1000-1200kg/saattir. Makinenin içerisinde yaklaşık 500 adet bıçak bulunmaktadır. Verimli mekanik çalışma sayesinde etiketin şişeden ayrılmasını tamamlar.

PET şişe yıkama geri dönüşüm tesisi için daha sonraki temizleme ve yeniden işleme verimliliğinin artırılması gerekmektedir.

Plastik PET şişe etiket sökme makinesinin özellikleri

- Makinemiz son derece verimlidir ve 1000-1200kg/saat çıkış.

- Bir 90-99% etiket kaldırma oranı. Yuvarlak şişeler için etiket kaldırma oranı 98-99%, düzleştirilmiş şişeler için ise 90-93%'dir.

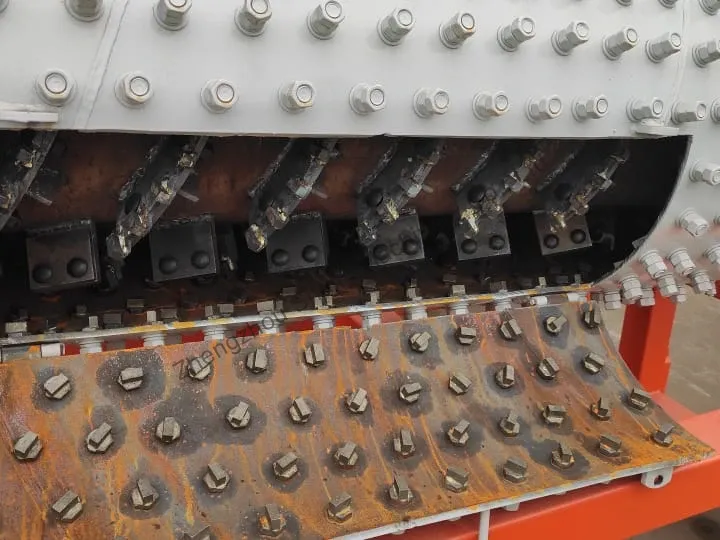

- Plastik etiket sökme makinemiz keskin ve dayanıklı 500 adet bıçak, yapılmış alaşım. PET şişelerden etiketlerin etkili bir şekilde kesilmesini ve çıkarılmasını sağlar.

- Shuliy etiketleme makinesi 8 mm dış duvar kalınlığı ve 4,3 m uzunluk. Bu sağlam ve dayanıklı bir yapıya sahiptir. Plastik geri dönüşüm hatlarında sürekli etiket çıkarılmasını sağlar.

- Yapabiliriz voltajı, gücü, bıçak miktarını özelleştirinvb. taleplerinizi karşılamak için.

PET etiket sökücü makinesinin parametreleri

- Modeli: SL-600

- Çıkış: 1000-1200kg/saat

- Etiket kaldırma oranı: >98%

- Güç: 11kw(makine gücü)+3kw(fan gücü)

- Uzunluk: 4,3 m

- Boyut: 4000*1800*1600mm

Yukarıdaki veriler referans amaçlıdır. Bu verilerden kapasite, etiket sökme oranı vb. öğrenebilirsiniz. Genellikle, plastik şişe etiket sökme makinesi plastik şişe geri dönüşüm yıkama tesisinde kullanılır.

Herhangi bir sorunuz varsa, daha fazla sınıflandırma için bizimle iletişime geçebilirsiniz!

PET şişe etiket sökme makinesinin uygulamaları

Etiket sökücü makine, her türlü plastik şişe, içecek şişesi, yenilebilir yağ şişesi, alüminyum kutu, cam şişe, meşrubat şişesi, deterjan şişesi, kozmetik şişesi ve diğerlerinden etiketleri çıkarmak için yaygın olarak kullanılır.

Plastik şişelerdeki etiketler nasıl çıkarılır?

PET şişe etiket sökme makinesinin çalışma prensibi iki ana adımdan oluşur: mekanik çıkarma ve rüzgar üfleme.

İlk olarak, PET şişelerdeki etiketleri hızlı ve doğru bir şekilde kesmek, soymak veya yırtmak için mekanik bıçaklar kullanılıyor. Etkin etiket çıkarılmasını sağlar.

Daha sonra fan, mekanik olarak çıkarılan etiketleri PET şişenin yüzeyinden uzağa üflemek için bir hava akışı oluşturacaktır. Bu, etiket çıkarma işleminin tamamını otomatik, temiz ve verimli hale getirir.

Son olarak, etiketsiz plastik şişeler boşaltılır.

PET etiket sökme makinesini doğru kullanma kılavuzu

- Kullanım kılavuzunu okuyun. Üretici tarafından sağlanan kullanım kılavuzunu dikkatlice okuyarak başlayın.

- Kılavuz, makinenin teknik özellikleri, güvenlik önlemleri ve uygun çalıştırma prosedürleri hakkında temel bilgileri içerir.

- Makine denetimi. Operasyondan önce PET şişe etiket sökme makinesini gözle görülür hasar, gevşek parça veya anormallik açısından inceleyin.

- Tüm bileşenlerin güvenli bir şekilde yerlerinde olduğundan ve makinenin içinde yabancı cisim bulunmadığından emin olun.

- Doğru kurulum. Plastik etiket çıkarma makinesini üreticinin talimatlarına göre kurun.

- Buna güç kaynağının bağlanması, ayarların yapılması ve tüm bileşenlerin doğru şekilde takıldığından emin olunması dahildir.

- Operasyonu başlatın ve izleyin. Makineyi belirtilen prosedüre göre çalıştırın.

- Düzgün çalıştığından emin olmak için başlangıç aşamasında işlemi yakından izleyin. Olağandışı sesleri, titreşimleri veya sorunları derhal çözün.

- Düzenli bakım. Kullanım kılavuzunda belirtildiği gibi düzenli bir bakım programı uygulayın.

- Bu, temizlemeyi, hareketli parçaların yağlanmasını ve aşınmanın kontrol edilmesini içerebilir.

- Bir bakım planına uymak, makinenin ömrünü uzatacak ve tutarlı performans sağlayacaktır.

PET şişe etiket sökme makinesi fiyatını sormak için bizimle iletişime geçin!

PET şişe etiketleme makinesinin fiyatını öğrenmek istiyorsanız lütfen bizimle iletişime geçmekten çekinmeyin! Profesyonel ekibimiz size detaylı ürün bilgisi ve teklifleri sunacaktır.

Bizimle iletişime geçerek özel ihtiyaçlarınızı karşılayacak özelleştirilmiş çözümler alabilirsiniz. Ekipman performansı, teknik özellikler veya fiyatlandırma hakkında sorularınız varsa, yardıma hazırız.