Shuliy PET bottle label remover machine is designed for efficiently stripping off the outer labels of all types of plastic bottles(or flattened bottles). It has a de-labeling rate of >98%.

This plastic label removal machine has a capacity of 1000-1200kg/h. There are about 500pcs of blades inside the machine. Through efficient mechanical operation, it completes the separation of the label from the bottle.

For the PET bottle washing recycling plant, it’s necessary to increase the efficiency of subsequent cleaning and reprocessing.

Features of plastic PET bottle label remover machine

- Our machine is highly efficient, with an output of 1000-1200kg/h.

- It has a de-labeling rate of 90-99%. The de-labeling rate for round bottles is 98-99%, and the rate for flattened bottles is 90-93%.

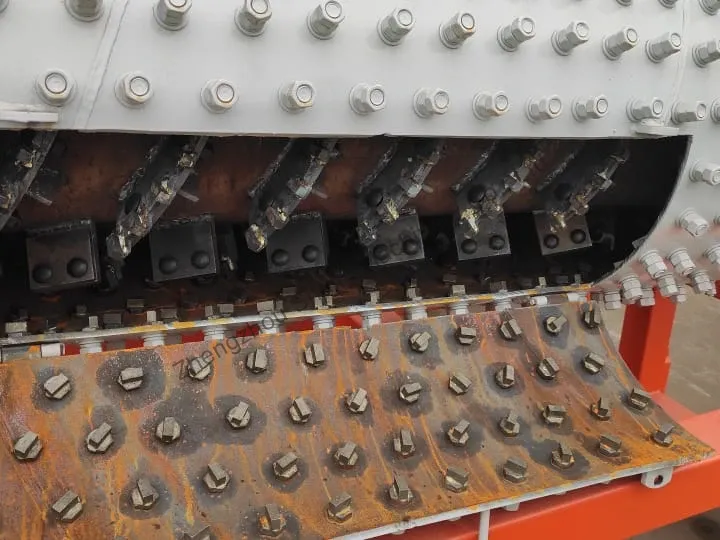

- Our plastic label remover machine has sharp and durable 500pcs of blades, made of alloy. It ensures effective cutting and removal of labels from PET bottles.

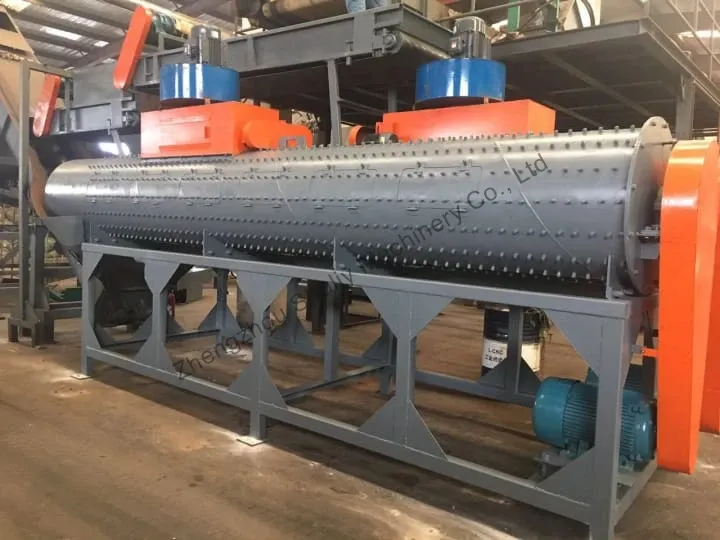

- Shuliy de-labeling machine has an outer wall thickness of 8mm and a length of 4.3m. This is built tough and durable. It enables continuous label removal in plastic recycling lines.

- We can customize voltage, power, blade quantity, etc. to meet your demands.

Parameters of PET label remover machine

- Model: SL-600

- Output: 1000-1200kg/h

- Delabeling rate: >98%

- Power: 11kw(machine power)+3kw(fan power)

- Length: 4.3m

- Dimension: 4000*1800*1600mm

The above data is for your reference. From this data, you can know the capacity, de-labeling rate, etc. Usually, the plastic bottle label removal machine is used in the plastic bottle recycling washing plant.

If any questions, welcome to contact us for more classifications!

Applications of PET bottle label remover machine

The de-labeling machine is widely used to remove labels from all kinds of plastic bottles, drinking bottles, edible oil bottles, aluminum cans, glass bottles, beverage bottles, detergent bottles, cosmetic bottles and others.

How to remove labels from plastic bottles?

The working principle of the PET bottle label remover machine consists of two main steps: mechanical removal and wind blowing.

Firstly, mechanical blades are used to quickly and accurately cut, peel or tear labels from PET bottles. It ensures efficient label removal.

Next, the fan will generate an airflow to blow the mechanically removed labels away from the surface of the PET bottle. This makes the entire label removal process automatic, clean and efficient.

Finally, plastic bottles without labels are discharged.

Guidance to correctly use PET label remover machine

- Read the user manual. Begin by carefully reading the owner’s manual provided by the manufacturer.

- The manual contains basic information on machine specifications, safety precautions, and proper operating procedures.

- Machine inspection. Before the operation, inspect the PET bottle label remover machine for any visible damage, loose parts or abnormalities.

- Ensure that all components are securely in place and that there are no foreign objects inside the machine.

- Proper setup. Set up the plastic label removing machine according to the manufacturer’s instructions.

- This includes connecting the power supply, adjusting the settings, and making sure all components are installed correctly.

- Start and monitor the operation. Start the machine according to the specified procedure.

- Closely monitor the operation during the initial phase to ensure proper functioning. Resolve any unusual sounds, vibrations or problems promptly.

- Regular maintenance. Carry out a regular maintenance program as outlined in the user manual.

- This may include cleaning, lubricating moving parts, and checking for wear.

- Adhering to a maintenance schedule will extend the life of the machine and ensure consistent performance.

Contact us to ask PET bottle label remover machine price!

If you want to know the price of PET bottle delabeling machine, please feel free to contact us! Our professional team will provide you with detailed product information and quotations.

By contacting us, you can get customized solutions to meet your specific needs. Whether you have questions about equipment performance, specifications or pricing, we are ready to help.