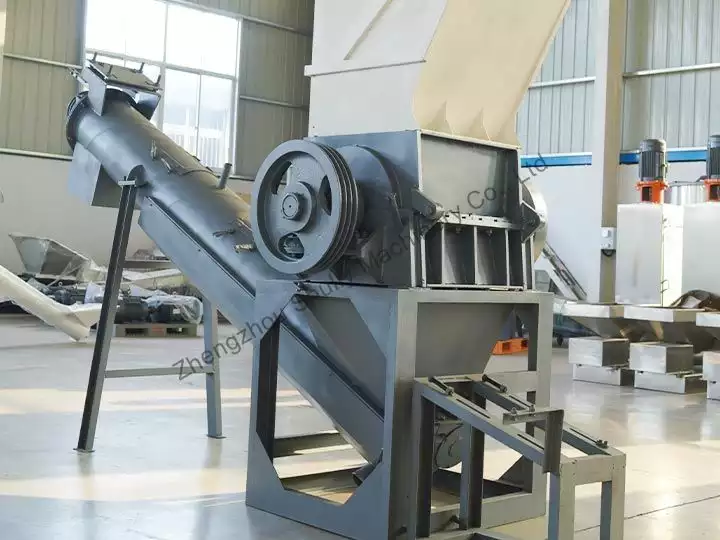

Shuliy friksiyon yıkama makinesi, plastik şişe geri dönüşüm hattında sıcak yıkama sonrası PET şişe flakelerini temizlemek için özel olarak tasarlanmıştır. Bu, PET şişe parçalarını çok daha temiz hale getirir. Ekipmanın kapasitesi 500-2000kg/saat.

Bu plastik sürtünmeli rondela sürtünmeye dayanıklı sürtünme tahtaları ile donatılmıştır. Enkazları gidermek ve çamur ve kumu filtrelemek için sürtünme temizlemeyi kullanır.

Makine normalde tek başına kullanılmaz. Genellikle PET şişe pullarını temizlemek için PET yıkama hattının bir parçası olarak kullanılır. İlgileniyor musun? Cevabınız evet ise, daha fazla ayrıntı için şimdi bizimle iletişime geçin!

Sürtünmeli çamaşır makinesinin avantajları

- Yüksek hızlı dönüş ve su akışını birleştirir. Sürtünmeli yıkama makinesi, yağ, tutkal ve toz gibi çeşitli yabancı maddeleri tamamen gidermek için bu yöntemi kullanır.

- Eğimli yerleştirme. Bu makine, plastik geri dönüşüm hattına bu şekilde yerleştirildiğinde malzeme kaldırma etkisine sahiptir.

- Düşük işletme maliyetleri. Temizleme işlemi sırasında sürtünmeli rondelanın enerji tüketimi düşüktür, bu da işletme maliyetlerinden tasarruf sağlar.

- Çeşitli plastik talaşların temizlenmesinde yaygın olarak kullanılır. Makine PET şişe pulları, PP/PE filmler vb. için uygundur.

Sürtünmeli çamaşır makinesinin teknik verileri

Kapasite: 500-1000kg/saat; 2000kg

Güç: 7.5kw; 15kw

Tank uzunluğu: 3000mm; 3500mm

Dış katman: 4mm

Bıçak kalınlığı: 6mm

Tarihten itibaren makine kapasitesi, gücü, tank uzunluğu vb. bilgileri öğrenebilirsiniz. Bu makinenin seçimi, plastik şişe geri dönüşüm hattınızın genel konfigürasyonuna bağlı olacaktır.

Daha detaylı bilgi istiyorsanız lütfen bizimle iletişime geçin, ihtiyaçlarınıza göre yapılandıralım.

PET şişe geri dönüşümünde neden sürtünmeli yıkama makinesi kullanılmalı?

PET şişe yıkama hattında sıcak yıkamanın ardından plastik sürtünme rondelası kullanılmaktadır.

PET levha ısıtıldıktan sonra yuvarlanacak, kanalizasyon ve sodayı kolayca tutacaktır. Sürtünmeli çamaşır makinesi, sıcak yıkama kazanından çıkan sodayı temizleyerek PH'ı düşürür. Bu, PH değerini 8'in altında tutacaktır.

Plastik şişe yıkama makinesinin çalışma prensibi

Sürtünmeli çamaşır makinemiz, PET pullarını temizleme solüsyonuyla birlikte dahili bir döner temizleme silindiri aracılığıyla döndürür.

Dönme sırasında pullar ile temizleme solüsyonu arasındaki sürtünme yüzeydeki kir ve yabancı maddelerin temizlenmesine yardımcı olur.

Temizlendikten sonra PET pulları bir drenaj sistemi aracılığıyla boşaltılır.

PET şişeler için ilgili plastik geri dönüşüm makineleri

PET şişe geri dönüşümünde en yaygın yöntem PET yıkama ipidir. Ana adımlar arasında etiket çıkarma, kırma, sıcak yıkama, sürtünmeli yıkama, kurutma vb. yer alır. Aşağıda referansınız için bazı makineler bulunmaktadır.

Bu makine, PET şişeleri yıkama ve geri dönüşüme hazırlamak için PET şişelerdeki etiketleri, bantları ve baskıları çıkarır.

Kullanılmış PET şişeleri küçük parçacıklara ayırarak sonraki işlem adımları için hammadde sağlar.

Yıkama işlemi sırasında PET şişe talaşlarını yüksek sıcaklıklarda yıkamak için sıcak su kullanır. Bu, kir ve kalıntıları giderir ve geri dönüştürülmüş malzemenin kalitesini artırır.

Bu makineler, PET şişelerin etkili bir şekilde geri dönüştürülmesini sağlamak için PET şişe geri dönüşüm sürecinde önemli bir rol oynamaktadır. Gerekirse, daha fazla makine detayı ve en iyi teklif için lütfen benimle iletişime geçin!