Shuliy friction washing machine is specially for cleaning PET bottle flakes after hot washing in the plastic bottle recycling line. It makes PET bottle chips much cleaner. The equipment has a capacity of 500-2000kg/h.

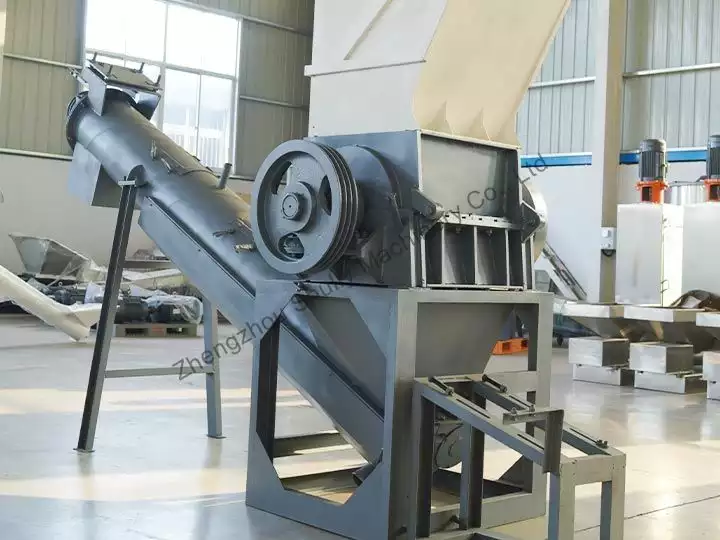

This plastic friction washer is equipped with rubbing boards, friction-resistant. It uses friction cleaning to remove debris and filter mud and sand.

The machine is not normally used alone. It’s usually used as part of the PET washing line to clean PET bottle flakes. Are you interested? If yes, contact us now for more details!

Advantages of friction washing machine

- Combining high-speed rotation and water flow. The friction washing machine utilizes this method to completely remove various impurities, such as oil, glue and dust.

- Inclined placement. This machine has a material lifting effect when placed this way in a plastic recycling line.

- Low operation costs. During the cleaning process, the friction washer has low energy consumption, saving operations costs.

- Widely used to clean various plastic chips. The machine is suitable for PET bottle flakes, PP/PE films, etc.

Technical data of friction washing machine

Capacity: 500-1000kg/h; 2000kg

Power: 7.5kw; 15kw

Tank length: 3000mm; 3500mm

Out layer: 4mm

Blade thickness: 6mm

From the date, you can know that the machine capacity, power, tank length, etc. The choice of this machine will depend on the overall configuration of your plastic bottle recycling line.

If you want more detailed information, please contact us and we will configure it according to your needs.

Why use friction washer machine in PET bottle recycling?

In the PET bottle washing line, the plastic friction washer is used after hot washing.

PET sheet will be rolled after heating, easily retaining sewage and lye. The friction washing machine cleans off the lye brought out from the hot washing pot, which lowers PH. This will keep the PH value less than 8.

Working principle of plastic bottle washing machine

Our friction washing machine rotates PET flakes with cleaning solution through an internal rotating cleaning cylinder.

During the rotation, the friction between the flakes and the cleaning solution helps to remove surface dirt and impurities.

After cleaning, the PET flakes are discharged through a drainage system.

Related plastic recycling machines for PET bottles

For PET bottle recycling, the most common method is the PET washing line. The main steps include de-labeling, crushing, hot washing, friction washing, drying and so on. Below are some machines for your reference.

PET bottle de-labeling machine

This machine removes labels, tapes and printing from PET bottles in order to prepare PET bottles for washing and recycling.

It crushes used PET bottles into small particles, providing raw material for subsequent processing steps.

It uses hot water to wash PET bottle chips at high temperatures during the washing process. This removes dirt and residue and improves the quality of the recycled material.

These machines play an important role in the PET bottle recycling process, ensuring that PET bottles are recycled effectively. If needed, please contact me for more machine details and the best quote!