PET şişe yıkama tesisi, maden suyu şişeleri, içecek şişeleri ve diğer PET ürünleri olabilen atık PET plastik şişelerin ve geri dönüşüm sisteminin elyaf, üç boyutlu şişe pulları ve filaman dereceli pullara ve diğer yüksek kaliteye dönüştürülmesi için özel olarak tasarlanmıştır. tel çekme, enjeksiyonlu kalıplama, kabarcıklı kullanım gibi alt endüstriler için değerli ürünler.

PET şişe yıkama tesisinin prosesi

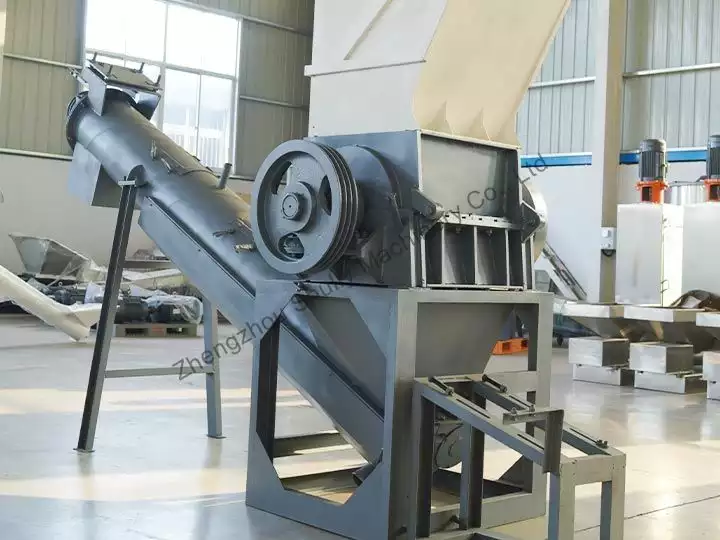

Ön arıtma: etiket çıkarma ve kırma

Atık PET şişeler önce etiketlerden etiket çıkarıcı makine ile çıkarılır ve ardından kırıcı ile kırılarak kırıntılara dönüştürülür.

Soğuk suyla yıkama

Ezilmiş PET pulları, çok aşamalı bir yıkama ve durulama işlemi yoluyla yüzeydeki yapışkanları uzaklaştırmak için soğuk suyla yıkama işlemine girer.

Yüksek sıcaklıkta sıcak su temizliği

Soğuk suyla temizliğin ardından PET kırıntıları, kalıntı lekelerinin ve yağlı maddelerin giderilmesini sağlamak için yüksek sıcaklıkta sıcak su temizleme hattı ile daha derin temizlemeden geçirilir.

Temizleme ve ayırma

Malzeme, yüzeydeki yabancı maddeleri fiziksel olarak temizleyen ve nem alma ve toz toplama için bir toz toplama cihazıyla donatılmış tambur sürtünmeli kuru temizleme makinesi kullanılarak verimli bir şekilde kuru temizlenir.

İnce yıkama ve kuru temizleme

Ayrılan plastik, PET şişe pullarının nihai çıktısının temiz ve yabancı maddelerden arınmış olmasını sağlamak amacıyla ince kumu, ince tozu ve diğer kalıntıları iyice temizlemek için tekrar kuru temizleme makinesine girer.

PET şişe pulları yıkama tesisinin özellikleri

Montaj PET şişe yıkama tesisi hattının tamamı, iyi çevre koruma performansına sahip, tamamen kapalı üç boyutlu bir tasarımı benimser. Filtreleme işleminden sonra su geri dönüştürülür ve tüm süreç, hava kirliliğini, su kirliliğini ve gürültü kirliliğini etkili bir şekilde azaltan ve ulusal çevre standartlarına tam uyumlu olan toz toplama ve gaz arıtma tesisleri ile donatılmıştır.

Montaj hattının yüksek derecede otomasyonu sayesinde, tüm üretim sürecini yalnızca 1-2 kişi tamamlayabilir, bu da üretim verimliliğini ve kaynak kullanımını büyük ölçüde artırır.

Daha fazla makine detayı için bizimle iletişime geçin!

If you are interested in plastiğe yeniden şekil verme şişeleri, bizimle iletişime geçin ve ihtiyaçlarınız için en uygun çözümü sunalım.