Plastiek wasmasjien spesialiseer in die skoonmaak en verwerking van gekneusde plastiekfilms, soos plastieksakke, verpakkingsfilms, landboufilms, ensovoorts. Hierdie wasmasjien het 'n kapasiteit van 100-500 kg per uur vir die skoonmaak van PP PE-films vir plastiekherwinning.

As jy plastiekfilms wil herwin, is hierdie toerusting nodig vir jou om te gebruik.

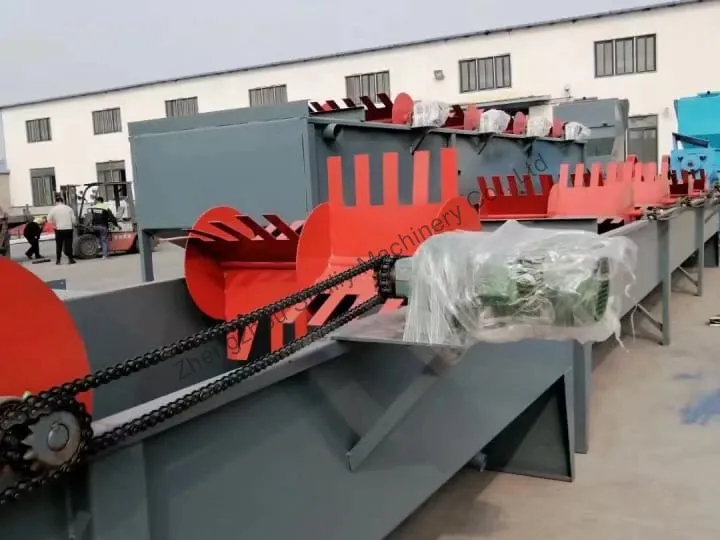

Struktuur van PP PE plastiek wasmasjien

Die struktuur van 'n PP PE-plastiekwastenk bestaan gewoonlik uit hoofmotor, skroef, gryptoestel en kettingstelsel.

Die motor is die kragbron om die hele wastenk aan te dryf, wat deur die kettingstelsel aan die gryptoestel gekoppel is sodat die gryper in die wastenk kan beweeg om die plastiekmateriaal te roer en skoon te maak.

Die beweging van die gryptoestel word deur die ketting gekoördineer sodat die plastiekfilms eenvormig in die wastenk skoongemaak word, wat 'n doeltreffende plastiekwasproses tot gevolg het.

Voordele van plastiek herwinning wasmasjien

- Stabiele prestasie: Glad lopende, maklike en veilige werking, lang lewensduur en gerieflike instandhouding.

- Sterk kopermotor: Dit verseker dat die masjien stabiel kan loop en die drywende materiaal gerieflik vinnig kan skei.

- Professionele tegnologie: Voldoende krag en duursaamheid is nie maklik om te breek nie om tyd en moeite te bespaar om gerieflik te gebruik.

- Duidelike effek: Goeie skoonmaak-effek, die masjiengeraas is klein, hoë doeltreffendheid en wye gebruik.

Tegniese data van plastiekfilmspoelmasjien

Model: SL-500

Kapasiteit: 100-500kg/h

Krag: 2.2kw

Lengte: 5m, 10m, 15m, 20m (lengte kan aangepas word)

Dikte: 5mm

Breedte: 1.5m

Hoogte: 1.5m

Die bogenoemde parameters is vir u verwysing wanneer u PP PE-filmherwinningsaanleg kies.

Die spesifieke vereiste uitset moet ooreenstem met die plastiekfilmherwinningslyn wat jy benodig. Jy kan ons kontak, vertel ons jou behoeftes, en ons sal dieselfde beste program vir jou wees.

Noodsaaklikheid om plastiekwasmasjien in plastiekherwinningslyn te gebruik

Die noodsaaklikheid om die plastiekfilmwastenk in 'n plastiekherwinningslyn te gebruik, lê in die vermoë daarvan om die plastiekmateriaal effektief skoon te maak na filmversnippering. Die hooffunksie van hierdie stap is om onsuiwerhede, ghries en oorblyfsels van die oppervlak van die plastiek te verwyder en sodoende die kwaliteit van die herwonne plastiek te verbeter.

Skoon plastiekfilm word makliker herverwerk vir die vervaardiging van nuwe plastiekprodukte, terwyl dit help om die las op die omgewing te verminder en volhoubare plastiekherwinning te bevorder.

Daarom, in die plastiekherwinningslyn, speel die plastiekafvalwastenk 'n sleutelrol in die versekering van die kwaliteit en volhoubaarheid van herwonne plastiekfilms.

Watter materiale kan met 'n plastiekwasmasjien gewas word?

- LDPE film: Lae-digtheid poliëtileen film, wat algemeen gebruik word vir plastieksakke en verpakkingsmateriaal.

- HDPE film: Hoëdigtheid poliëtileenfilm wat in 'n verskeidenheid toepassings gebruik word, insluitend landboufilm en industriële verpakking.

- PP film: Polipropileenfilm wat in verpakking, tekstiele en ander produkte gebruik word.

- PET film: Poliëtileentereftalaatfilm vir bottels, bakkies en ander verpakkingsmateriaal.

- PVC film: Polivinielchloriedfilm word in 'n verskeidenheid plastiekprodukte gebruik, insluitend blisterpakkies en konstruksiemateriaal.

- PS film: Polistireenfilm vir verpakking, voedselhouers en weggooigoed eetgerei.

- Veellaag film: Veellaagfilm wat uit verskillende plastieklae bestaan.

- Landbou film: Word gebruik in landbouboerdery.

Watter ander masjiene word in die plastiese filmherwinningslyn gebruik?

Vir hierdie plastiekherwinninglyn kan masjiene wat gebruik word, wees plastiekfilm versnipperaar → plastiekfilm spoelbak → plastiek droogmasjien → plastiek pelletiseermasjien → plastiek pellet snymasjien.

Hierdie masjiene maak 'n hele plastiekherwinningslyn uit wat jou kan help om plastiekfilm vir herwinning te herwin en te verwerk, wat jou help om afval in wins te omskep.