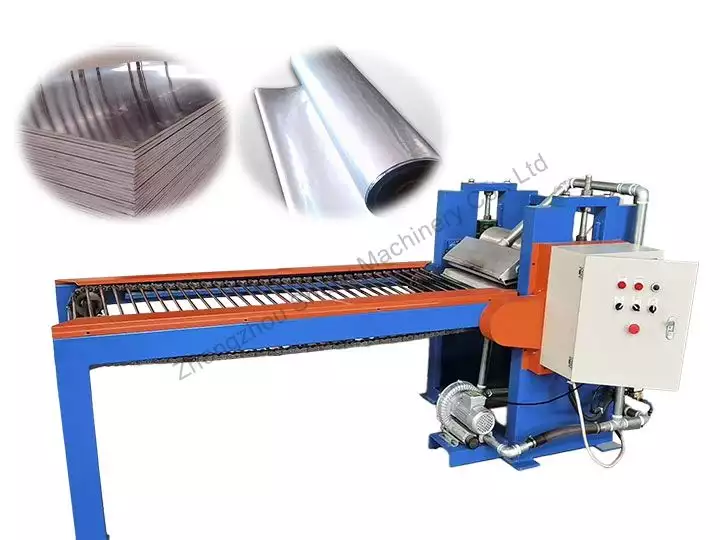

Shuliy ACP bord verhitting skeidingsmasjien skei effektief die aluminium laag van die plastiek laag deur die ACP plaat te verhit en die bindmateriaal te smelt. Dit kan ACP panele van 4 ton per 8 uur verwerk, afhangende van die bordgrootte.

Dit kan alle soorte saamgestelde aluminiumpanele hanteer. Die finale produkte is aluminiumplate en PE-plate vir hergebruik en herwinning. Ons ACP-herwinningsmasjien is baie gewild in die wêreldmark, soos Rusland, Uzibiestan, die Verenigde State, Benin, ens.

Soek jy 'n herwinningsmasjien vir saamgestelde aluminiumvliegtuie? Indien wel, kontak ons nou! Ons sal die beste oplossing bied om u besigheid te bevoordeel.

Voordele van ACP-bordverhittingstroopmasjien

- Dit kan ACP-plate van 2-8 ton per dag hanteer, wat hoogs doeltreffend is.

- Hierdie masjien is klein en maklik om te gebruik.

- Ons ACP-bordverwarmingskeimasjien is fabrieksdirekte verkope en baie koste-effektief.

- Die masjien skei die aluminium van plastiek deur saamgestelde panele te verhit sonder omgewingsbesoedeling.

- Die finale produkte kan hergebruik word, met beter maatskaplike en ekonomiese voordele.

- Klein belegging, hoë doeltreffendheid en vinnige belegging keer terug.

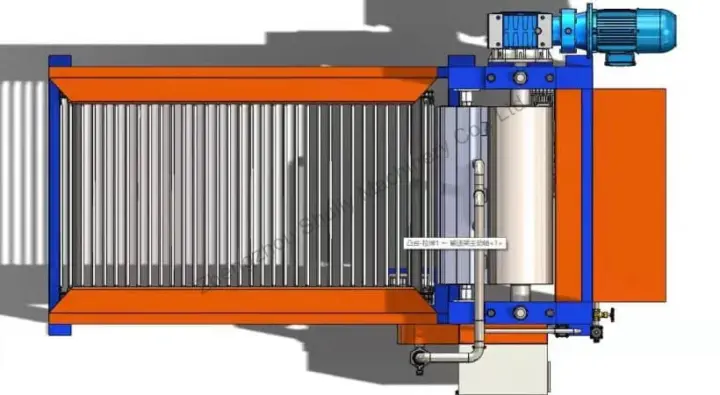

Tegniese parameters van saamgestelde paneel skei masjien

| Model | SL-600 | SL-800 | SL-1000 |

| Kapasiteit | 4T/ 8 uur | 4T/ 8 uur 4T/ 8 uur | 4T/ 8 uur |

| Werkwydte | 400mm | 600 mm | 800 mm |

| Toepaslike materiale | Alle soorte ACP materiaal | Alle soorte ACP materiaal | Alle soorte ACP materiaal |

| Spanning | 380V/2.2kw 50HZ/3 fase (motor kan aangepas word) | 380V/2.2kw 50HZ/3 fase (motor kan aangepas word) | 380V/2.2kw 50HZ/3 fase (motor kan aangepas word) |

| Gasverbruik | 2,5 kg/h | 3,75 kg/h | 4 kg/h |

| Grootte | 1400mm* 1500mm* 1100mm | 3900mm* 2300mm* 1100mm | 3900mm* 2500mm* 1100mm |

| Gewig | 800 kg | 1200 kg | 1300 kg/h |

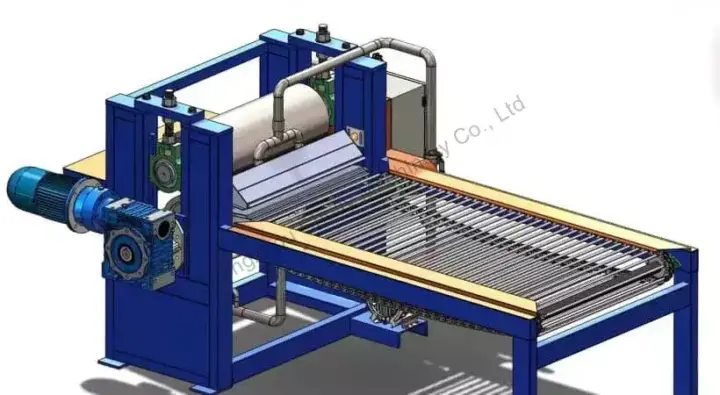

Die spesifikasies van die bandvervoerband (ooreenstem met SL-600 ACP-bordverhittingskeimasjien) is soos volg:

- Naam: kettingrataangedrewe aluminium-stroopplatform

- Model: Bt-1000mm bandvervoerband

- Grootte: 1500*1000*1000 mm

- Breedte: 200 kg

Uit die bogenoemde data kan u weet dat ons SL-600 ACP-verhittingstroopmasjien 'n kapasiteit van 4-8t per dag het en geskik is vir alle soorte saamgestelde panele. As jy enige saamgestelde panele het wat verwerk moet word, is welkom om ons te kontak vir meer besonderhede!

Struktuur van ACP-bordverwarmingskeimasjien

Die masjien is baie eenvoudig en maklik om te verstaan. Dit bestaan uit inlaat, skeidingstoestel, drom, uitlaat, ratkas, beheerkas, ens.

Hoe werk die ACP-bordverwarmingskeier?

- Wanneer jy werk, stuur ACP-plate in die inlaat.

- Dan word dit na die verwarmingsarea gestuur. Die plate word deur die verhittingstelsel verhit om die plastieklaag sag te maak en die bindingskrag tussen die aluminiumlaag en die plastieklaag te verswak.

- Vervolgens word die aluminiumlaag van die plastieklaag geskei deur wind en vibrasie te gebruik.

- Laastens word die geskeide aluminium en plastiek afsonderlik ingesamel om die hele herwinningsproses te voltooi.

Wat is die prys van ACP-herwinningsmasjien?

Die prys van 'n ACP-velstropper sal verskil volgens verskillende modelle, verwerkingskapasiteit, tegniese konfigurasie en ander faktore. Oor die algemeen wissel die prys van 'n standaard ACP-bordverwarmingskeimasjien van 'n paar duisend dollar.

Die spesifieke prys sal beïnvloed word deur die toerustingkonfigurasie, kapasiteit en vervaardiger.

Dit word dus aanbeveel dat u die betrokke verskaffers raadpleeg vir 'n gedetailleerde kwotasie voor aankoop.

Hoe kry jy 'n geskikte een by Shuliy?

Wanneer jy die regte ACP-skeiermasjien by Shuliy wil koop, moet jy twee rigtings oorweeg: die oorwegings by die aankoop van die masjien en die aankoopproses. Deur hierdie twee aspekte in ag te neem, kan jy verseker dat jy die mees geskikte ACP-bordverwarmingskeimasjien vir jou behoeftes koop.

Oorwegings by die aankoop van die masjien

- Verwerkingskapasiteit: kies die regte kapasiteit vir jou produksieskaal, Shuliy bied 'n wye reeks modelle van klein tot groot.

- Toerusting prestasie: fokus op die skeidingsdoeltreffendheid, energieverbruik en bedryfstabiliteit van die toerusting. Ons toerusting is streng getoets om hoë doeltreffendheid en stabiliteit te verseker.

- Na-verkope diens: kies die verskaffer wat perfekte na-verkope diens lewer. Shuliy verskaf installasie, ingebruikneming, tegniese ondersteuning en ander dienste om te verseker dat kliënte geen bekommernisse het nie.

- Pasgemaakte aanvraag: as daar spesiale behoeftes is, kan u persoonlike vereistes aan Shuliy voorlê. Ons bied pasgemaakte oplossings volgens spesifieke jou behoeftes.

Aankoop proses

- Aanvanklike konsultasie

- Tegniese ondersteuning en pasgemaakte oplossings

- Kwotasie en kontrak ondertekening

- Betaal 'n deposito en produksie

- Kwaliteit inspeksie

- Toerusting aflewering

- Opvolg ondersteuning en instandhouding

Bogenoemde twee aspekte word gelyktydig uitgevoer. Met verwysing na bogenoemde, kan u seker wees dat u 'n ACP-bordverwarmingskeimasjien koop wat aan u behoeftes voldoen en deurlopende tegniese ondersteuning en diens van Shuliy ontvang.

Ander tipes ACP-bordverwarmingskeimasjien

Hierdie ACP-velstroopmasjien is 'n outomatiese verwarmingstipe.

Die wydte van die vel wat gestroop moet word, is 50 cm. En die dikte van aluminiumvel is 8 tot 50 sy. Dit het 'n produksievermoë van ongeveer 3t per dag.

Hierdie tipe afval-ACP-stroopmasjien gebruik vuurroosterskeiding.

Dit het twee geskeide dele. As jy meer besonderhede wil hê, is welkom om ons nou te kontak!

Verwante metaalherwinningstoerusting

As 'n professionele herwinningsmasjien vervaardiger en verskaffer, het ons ook ander metaal herwinningsmasjiene te koop. Soos metaal versnipperaar, metaal baler, metaal skêr, koper draad herwinningsmasjien, metaal chips briketmasjien, ens.

Maak nie saak watter soort afvalmetaal materiale jy wil verwerk nie, ons toerusting kan aan jou behoeftes voldoen. Waarop wag jy? Kontak ons nou en ons sal jou die beste oplossing bied.