Ei houer masjien is om ei houers te maak van papierpulp gemaak deur afvalpapier, karton, tydskrifte, ens., met 'n kapasiteit van 1000-7000pcs/h. Hierdie masjien help jou om 'n wins uit afval te maak.

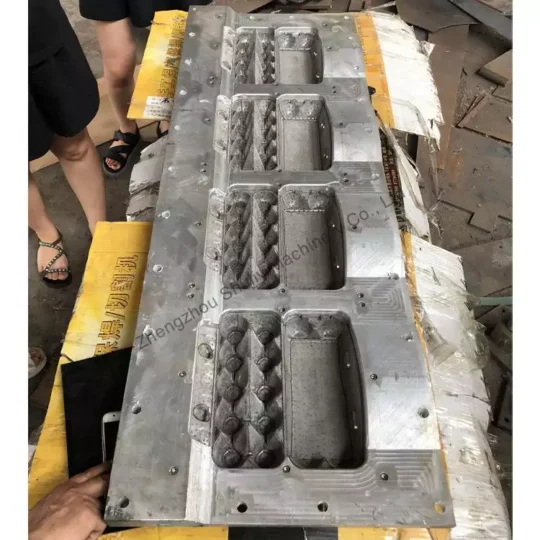

Ons eierbakkiemaakmasjien kan nie net tradisionele 6 of 12 eierpakke vervaardig nie, maar kan ook papierbakkies in 'n verskeidenheid verskillende groottes en vorms vervaardig om aan verskillende markvereistes te voldoen.

Eierskinkbordmasjiene het 'n belangrike rol om te speel op die gebied van volhoubare verpakking en eko-vriendelike verpakking, wat help om afval en die gebruik van plastiekverpakking te verminder en omgewingsvriendelike en volhoubare verpakkingsoplossings te bevorder.

Video van pulp eier skinkbord masjien

1000-1500 stuks/h eierbakmasjien werkende video

2500-3000 stuks / h papier eier skinkbord masjien werk video

4000-6000 stuks / h papierpulp gietmasjien werk video

Beskikbare eierbak masjien te koop

As 'n professionele vervaardiger en vervaardiger van herwinningstoerusting, word ons in klein, medium en groot verdeel volgens die aantal gevormde stukke per uur, sien asseblief my gedetailleerde inleiding hieronder

Warmverkopende klein eierskinkbordmaakmasjien: 1000-1500 stuks/h

- Aantal gietstukke: Gewoonlik is die aantal gietstukke klein, soos 1000pcs/h, 1500pcs/h.

- Produksie kapasiteit: Klein masjiene is geskik vir begin- of kleinskaalse produksie met lae produksiekapasiteit.

- Kragvereiste: Minimale kragvereiste, geskik vir kleinskaalse produksieplekke.

- Gebruike: Klein eierbakmasjien is geskik vir kleinskaalse eierverpakking soos familieplase, kleinboere en klein besighede.

| Model | Kapasiteit | Krag | Spanning | Gewig | Papierverbruik | Waterverbruik | Grootte (vormmasjien) | Droog metode |

| SL-3*1 | 1000 stuks/h | 38kw | 380V, 50HZ | 2500kg | 80 kg/h | 160 kg/h | 2600*2200*1900mm | Droog natuurlik of gebruik 'n droër |

| SL-4*1 | 1500 stuks/h | 38kw | 380V, 50HZ | 3000 kg | 120 kg/h | 240 kg/h | 2800*2200*1900mm | Droog natuurlik of gebruik 'n droër |

As jy 'n beginonderneming in hierdie bedryf wil hê, is hierdie tipe papierbakmasjien die beste keuse vir jou.

Mediumgrootte papierpulp gietmasjien: 2000-3000 stuks / h

- Aantal stukke: Gewoonlik is die aantal stukke tussen groot en klein, bv. 2000-2500 stuks/h, 2500-3000 stuks/h.

- Produksie kapasiteit: Mediumgrootte masjiene het 'n matige produksievermoë en is geskik vir mediumgrootte produksiebehoeftes.

- Kragvereiste: Laer kragvereiste in vergelyking met groter masjiene.

- Gebruike: Mediumgrootte eierbakmasjien is geskik vir mediumgrootte eierverpakkingsproduksie, geskik vir plase en klein verpakkingsondernemings.

| Model | Kapasiteit | Krag | Spanning | Gewig | Papierverbruik | Waterverbruik | Grootte (vormmasjien) | Droog metode |

| SL-3*4 | 2500 stuks/h | 55kw | 380V, 50HZ | 4000 kg | 200 kg/h | 400 kg/h | 2900*1800*1800mm | Baksteenoonddroog of meerlaagdroër |

| SL-4*4 | 3000 stuks/h | 60 kw | 380V, 50HZ | 4800kg | 240 kg/h | 480 kg/h | 3250*1800*1800mm | Baksteenoonddroog of meerlaagdroër |

Hierdie tipe is geskik vir mediumskaalse eierskinkbordvervaardigingsaanleg.

Grootskaalse eierbakmasjien: 4000-6000 stuks/h

- Aantal stukke gevorm: Gewoonlik kan verskeie eierbakkies gelyktydig gevorm word, bv. 4000-5000 stuks/g, 5000-6000 stuks/h.

- Produksie kapasiteit: Die produksievermoë van groot masjiene is gewoonlik meer as 'n paar duisend eierbakkies per uur.

- Kragvereistes: Weens die hoë produksievermoë word 'n groot kragtoevoer gewoonlik benodig.

- Gebruike: Groot eierbakmasjiene is geskik vir grootskaalse eierverpakkingsproduksie en word gewoonlik in groot plase of pakhuise gebruik.

| Model | Kapasiteit | Krag | Spanning | Gewig | Papierverbruik | Waterverbruik | Grootte (vormmasjien) | Droog metode |

| SL-4*8 | 4000 stuks/h | 95 kw | 380V, 50HZ | 7000 kg | 320 kg/h | 640 kg/h | 3250*2300*2500mm | Baksteenoonddroog of meerlaagdroër |

| SL-5*8 | 5000 stuks/h | 95 kw | 380V, 50HZ | 8000kg | 400 kg/h | 800 kg/h | 3700*2300*2500mm | Baksteenoonddroog of meerlaagdroër |

| SL-6*8 | 6000-7000 stuks/h | 120kw | 380V, 50HZ | 10 000 kg/h | 480 kg/h | 960 kg/h | 3200*2300*2500mm | Baksteenoonddroog of meerlaagdroër |

As jy sterk finansiële ondersteuning het en grootskaalse produksie wil begin en vinnig wins wil maak, is hierdie groot model jou beste keuse.

Hoe om kwaliteit eierbakkies te maak?

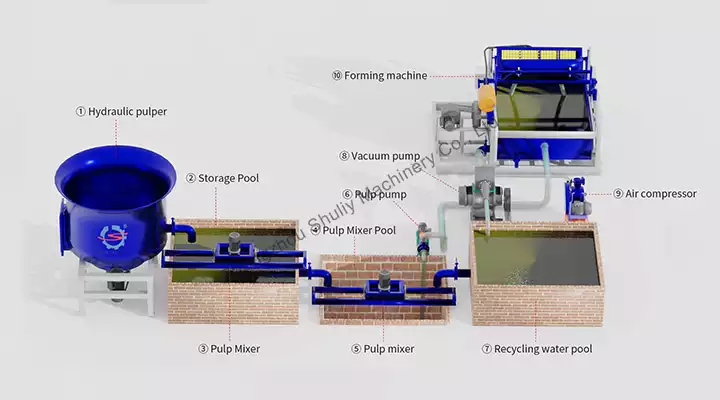

Verpulp

Verpulping is die eerste stap in die vervaardiging van eierskinkborde en behels die vermenging van afvalpapier of pulp met water om 'n pulpaftreksel te vorm. Op hierdie stadium word die afvalpapier fyngedruk en gemeng, en die pulpvoorraad van die pulpsel word dan in die daaropvolgende vormingstadium ingevoer.

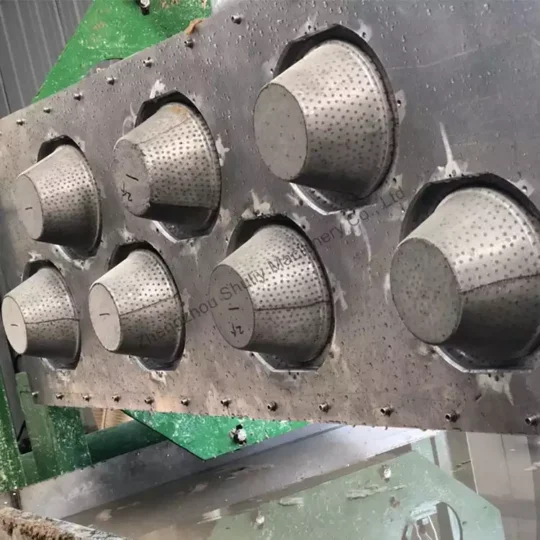

Vorming

In die vormingstadium word die pulpaftreksel in die eierbakmasjien getrek en dan in vorms ingespuit om in die verlangde eierbakvorm en -grootte gevorm te word. Eierbakmasjiene het gewoonlik veelvuldige vorms om verskillende tipes en groottes eierbakkies te produseer.

Droog

Die gevormde eierbakkies moet gedroog word om oortollige water te verwyder en om te verseker dat die bakkies die vereiste voginhoud bereik. Droging kan gedoen word deur verskillende metodes soos sondroging, natuurlike ventilasiedroging of warmlugdroging, afhangende van die skaal van produksie en beskikbare hulpbronne.

Verpakking

Laastens word die gedroogde eierbakkies na die verpakkingsarea gestuur, waar dit gewoonlik saamgebondel of in bakkies of sakke gestapel word. Verpakking kan aangepas word om drukwerk en handelsmerk in te sluit.

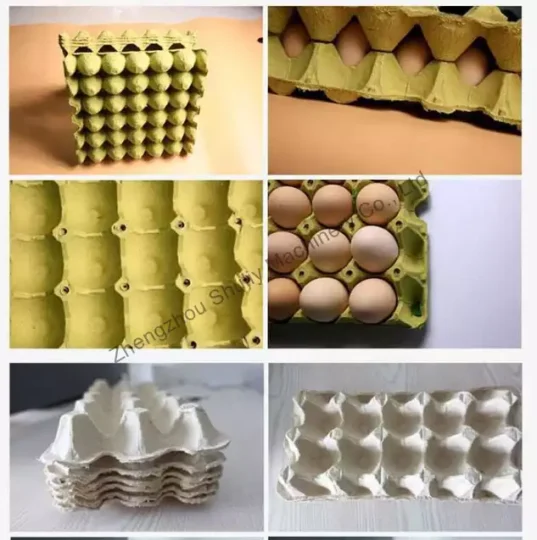

Finale produkte van papier eier skinkbord masjien

- Eierbakkies: Die mees algemene tipe eierskinkbord wat gebruik word vir die verpakking van eiers, gewoonlik met 'n kapasiteit van 6 of 12 of 30 eiers.

- Kwartel eierbakkies: Kompakte papierbakkies vir die pak van kwarteleiers, akkommodeer eiers van klein voëltjies.

- Vrugtebakkies: Word gebruik vir die verpakking van vrugte soos appels, lemoene en pere, wat ondersteuning en beskerming bied.

- Eetgerei skinkborde: Gebruik vir eetgerei en aandeteborde, wat gerieflike restaurantdiens verskaf.

- Elektroniese voering pakke: Word gebruik vir voering soos dié vir TV's, rekenaars en huishoudelike toestelle.

- Blompotbakkies: Vir die vashou van plante en blomme, verskaffing van stabiliteit en horisontale ondersteuning.

- Binnesoolbakkies: Pakkette skoene produkte, wat die vorm en kwaliteit van die binnesole beskerm.

- Groentebakkies: Verpakking van groente soos tamaties, komkommers en wortels, wat ventilasie en beskerming bied.

- Eend eierbakkies: Spesiaal ontwerp vir die verpakking van eendeiers, wat die grootte en vorm van die eiers akkommodeer.

Benewens dit, kan ons ook jou voltooide produk aanpas om by jou behoeftes te pas, insluitend grootte, vorm en drukwerk. Die buigsaamheid van die outomatiese eierskinkbordmasjien maak dit 'n noodsaaklike deel van volhoubare verpakkingsoplossings vir 'n wye reeks nywerhede en produktipes.

Vorms vir eierbakmasjien te koop

Eierbakmasjien in eierbakproduksielyn

Shuliy papierpulp vormmasjien is een van die kern toerusting in papier houer produksielyn, wat 'n sleutelrol speel in die maak van ei houers. Spesifiek sluit die rol van ei houer masjien die volgende aspekte in:

Pulp Vorming

Vochtverwydering

Ei houer vorming

Afvoer en vervoer

Die werkverrigting en stabiliteit van die eierbakmasjien is van kardinale belang vir die werking van die hele eierbakverwerkingslyn, en die presiese werking daarvan verseker die kwaliteit en produktiwiteit van die eierbakkies. Eierbakmasjiene speel dus 'n belangrike rol in die vervaardiging van volhoubare verpakking en omgewingsvriendelike verpakking, wat help om afval en die gebruik van plastiekverpakking te verminder.

Tipes eierbak droog

Eierskinkborddroog is 'n belangrike stap in die eierbakvervaardigingsproses en word gebruik om vog uit die pulp te verwyder om die eierbak op die verlangde vogvlak te bring. Hieronder is drie algemene maniere om eierbakkies te droog en die voordele daarvan:

Die 1ste manier: natuurlike droog

- Lae koste: Natuurlike droging vereis geen bykomende energie nie en het dus lae bedryfskoste.

- Omgewingsvriendelik: Produseer geen emissies nie en is omgewingsvriendelik.

- Eenvoudig en uitvoerbaar: Geskik vir gebiede met beperkte hulpbronne, geen duur toerusting nodig nie.

- Wye toepaslikheid: Doeltreffend in warm, droë klimate.

Die 2de metode: baksteen linne droog

- Eenvormige droog: Baksteenoonde verskaf eenvormige temperatuur en humiditeit, wat help om die kwaliteit van die eierbak te handhaaf.

- Ruimtebesparend: Hierdie metode is gewoonlik vertikaal in konstruksie, wat vloerspasie bespaar.

- Hoogs beheerbaar: Die temperatuur en humiditeit van die baksteenoond kan aangepas word om aan die vereistes van verskillende produkte te voldoen.

- Geskik vir massaproduksie: Geskik vir die vervaardiging van hoëvolume eierskinkborde.

Die 3de metode: metaal droër masjien

- Doeltreffend en vinnig: Metaaldroging is gewoonlik vinnig en verhit vinnig, wat bydra tot verhoogde produktiwiteit.

- Presiese beheer: Presiese temperatuur- en humiditeitsbeheer vir 'n wye reeks produkte.

- Aanpasbaar by 'n wye reeks produkte: dit kan gebruik word om ander papierprodukte benewens eierbakkies te droog.

Elke droogmetode het sy eie unieke voordele en die keuse van die mees geskikte metode hang gewoonlik af van die skaal van produksie, beskikbare hulpbronne en produkvereistes.

Natuurlike droging is geskik vir kleinskaalse en beperkte hulpbronne, steenoonddroging is geskik vir grootskaalse produksie waar eenvormige droging vereis word, en metaaldroging is geskik waar doeltreffende en vinnige droging vereis word. Jy kan die mees geskikte droogmetode vir jou behoeftes kies.

Navrae eier skinkbord masjien prys!

Soek jy 'n oplossing vir die herwinning van afvalpapier-eierbakproduksie? Maak gou en kontak ons, ons kan die optimale oplossing vir jou behoeftes verskaf.