Дробилка для EPS-пены также известна как измельчитель пены, это механическое устройство, специально разработанное для измельчения пены (EPS, XPS, EPP, EPE, PU и др.) на мелкие частицы или фрагменты.

Эти мелкие частицы часто используются для переработки материалов или других целей посредством ряда процессов, например, в машинах для гранулирования пластика.

Преимущества дробилки пенополистирола

- Эффективная обработка: Измельчитель пены может эффективно измельчать пену, значительно увеличивая скорость обработки и экономя время и трудозатраты.

- Повторное использование материалов: Кусочки измельченного пенопласта можно перерабатывать и регенерировать для использования в производстве новых пенопластовых изделий, таких как упаковочные материалы, изоляционные материалы, наполнители и т. д.

- Экологически чистый: Сокращая объем отходов пенопласта, измельчитель пенополистирола помогает снизить нагрузку на свалки и мусоросжигательные предприятия, снижая негативное воздействие пластиковых отходов на окружающую среду.

- Многоцелевой: Машина для дробления пенополистирола подходит для широкого спектра типов пенопласта, включая пенополистирол и пенополиэтилен, и имеет широкий спектр применения.

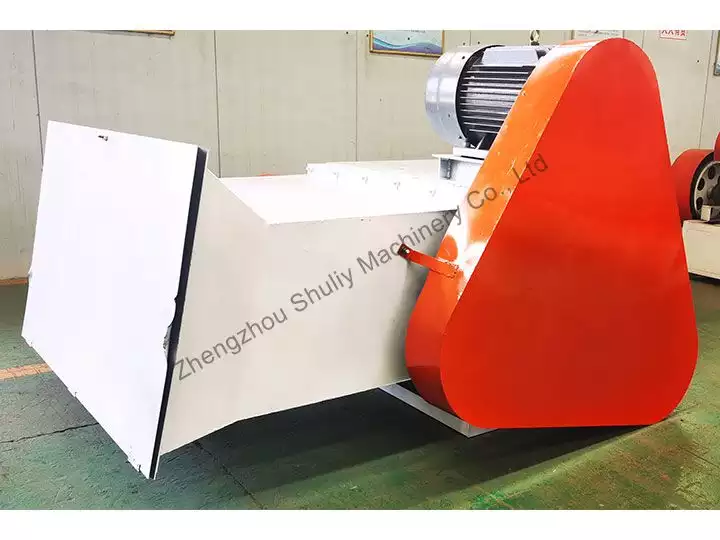

Технические параметры горизонтального измельчителя пены

| Модель | Емкость | Размер порта подачи | Власть | Общий размер |

| СЛ-800 | 250-300 кг/ч | 800*600 мм | 5,5 кВт | 1250*1290*660 мм |

| СЛ-1000 | 300-350 кг/ч | 1000*600 мм | 5,5 кВт | 1250*1530*660 мм |

| СЛ-1200 | 400-450 кг/ч | 1200*600 мм | 7,5 кВт | 1300*1730*700 мм |

| СЛ-1500 | 450-500кг/ч | 1200*600 мм | 11кВт | 1600*2200*800 мм |

Какой пенопласт можно измельчить с помощью дробилки для пенополистирола?

Область применения измельчителя пены включает в себя дробление таких материалов, как EPS, XPS, EPP, EPE, PU и др. Он широко используется для отходов пены, упаковочной пены, одноразовых контейнеров для еды, полиуретановых теплоизоляционных плит, экструзионных пластиковых плит, исчезающих форм и плит из каменной ваты, пенопластовых коробок, теплоизоляционных плит, KT-плит, материалов, генерирующих тепло и т.д.

Зачем использовать измельчитель пенополистирола для переработки пенопласта?

- Уменьшение отходов: Измельчитель пенополистирола помогает уменьшить объем отходов пенопласта, снижая нагрузку на свалки и мусоросжигательные предприятия.

- Повторное использование ресурсов: Измельченный пенопласт можно переработать для изготовления нового пенопласта или других пластиковых изделий.

- Защита окружающей среды: Сокращая отходы пены, дробилка пены помогает снизить нагрузку на окружающую среду.

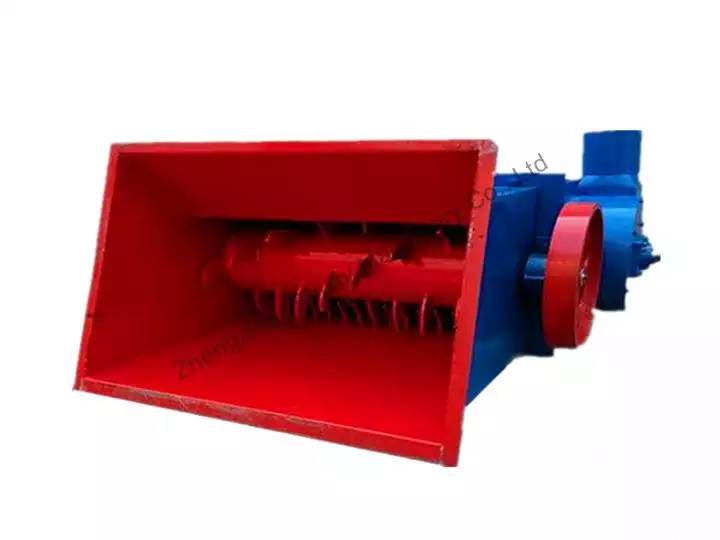

Рабочий процесс измельчения пенопласта

Кормление

Отходы пенопласта сбрасываются во входное отверстие дробилки пенопласта.

Резка и шинковка

Как только отходы попадают в дробилку пенополистирола, внутренняя система лопастей начинает вращаться. Эти острые лезвия используются для резки и измельчения пенополистирола, превращая его в мелкие частицы или крошку.

Скрининг

Измельченные частицы пропускают через систему сит для отделения частиц желаемого размера. Экран можно изменить, чтобы отрегулировать размер частиц по мере необходимости.

Увольнять

Наконец, измельченные гранулы пенополистирола выгружаются через выпускное отверстие для дальнейшей переработки или переработки.

Другие машины для переработки пластмассовых отходов

Помимо дробилки для пены, у нас также есть дробилка для пластика, дробилка для PET-бутылок, гранулятор для пластика, удалитель этикеток с PET-бутылок и другие машины для переработки пластика. Эти машины имеют хорошее качество и производительность, которые являются незаменимым оборудованием для переработки.

Запрос на цену машины для измельчения пены!

Ищете дробилку для пены? Или для любого другого типа измельчителя пластика? Свяжитесь с нами, наши профессиональные менеджеры предоставят вам наиболее подходящее решение в соответствии с вашими потребностями.