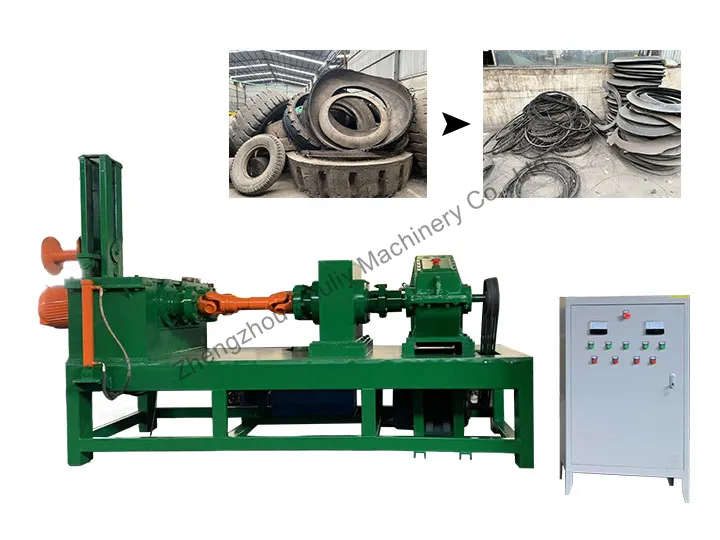

Shuliy OTR tire steel ring separator efficiently separates steel wires from the rims of large-sized engineering tires ranging from 1400 to 4000 mm in diameter, thereby avoiding the safety hazards and low efficiency associated with traditional cutting methods. The OTR tire bead wire extractor is hydraulically driven, ensuring smooth operation, and can complete the separation of a tire rim within 2 to 5 minutes, significantly enhancing recycling efficiency.

Usually, this off-the-road tire wire remover is used in the used OTR tire recycling stations, large-scale mining and construction equipment, environmentally friendly recycling plants, construction machinery dismantling industry, etc. If interested, welcome to contact us at any time for more details!

Technical parameters of OTR tire steel ring separator

Our hydraulic OTR tire steel wire separator takes 2-5 minutes to remove one tyre steel rim. It utilizes a 35.5 kW motor to operate and weighs 6,200 kg. When shipped, the whole machine is transported and no wooden box is required.

| Name | OTR tire steel rim separator |

| Capacity | 2-5 minutes per rim |

| OTR tire size to be processed | 1400-4000mm tire bead |

| Power | 35.5kw |

| Weight | 6200kg |

| Size | 3.65*2.1*1.95m |

| Packaging method | No wooden package, entire machine transported |

Advantages of OTR tire bead wire extractor

- Suitable for large-sized tire processing

- Shuliy OTR tire steel ring separator is widely applicable to mining vehicles, loaders, large-scale construction machinery tires, and other similar applications.

- Robust structure and long service life

- The OTR tire steel wire separator machine features a thickened steel plate structure design combined with a heavy-duty hydraulic system, ensuring stable operation even under heavy loads and high-intensity work conditions.

- Simple operation and high automation

- Equipped with a user-friendly interface, on-site operators can operate the machine after minimal training, reducing labor costs.

- High recycling value

- The separated steel wires maintain high integrity, facilitating subsequent sorting, recycling, and resource reuse, thereby enhancing overall profit margins.

Why use OTR tire wire removal machine in OTR tire recycling?

In the recycling and processing of used OTR engineering tires, the OTR tire steel ring separator plays a very important role. OTR tires are large in size, complex in structure, and contain a high amount of steel, making them difficult to process efficiently with ordinary equipment. Therefore, in actual recycling, the use of a wire removal machine has become a necessary choice. Its necessity is reflected in:

- Effectively separate steel wire rings, reducing the difficulty of subsequent processing

- Improve steel wire recovery rates, enabling resource reuse

- Ensure operational safety and reduce human resource consumption

- Compatible with various large OTR tires, improving processing flexibility

For companies engaged in the processing of used engineering tires, this is an indispensable piece of specialized equipment.

Reasons to choose Shuliy as OTR tire steel ring separator supplier

We have extensive experience in the production of engineering tire recycling equipment, offering customized solutions, remote technical guidance, and overseas services to help customers resolve various practical issues in tire dismantling. If you are facing challenges in separating steel wires from large tires, this OTR rim separator is your efficient, safe, and reliable choice.

We also provide the one-stop solution for OTR tire recycling:

- OTR tire sectioning machine

- OTR tire cutting machine & OTR tire bead wire extractor

- Tyre shredding machine

- Tire rubber grinding and screening unit

For more information on equipment details, quotes, or video materials, please feel free to contact us at any time!