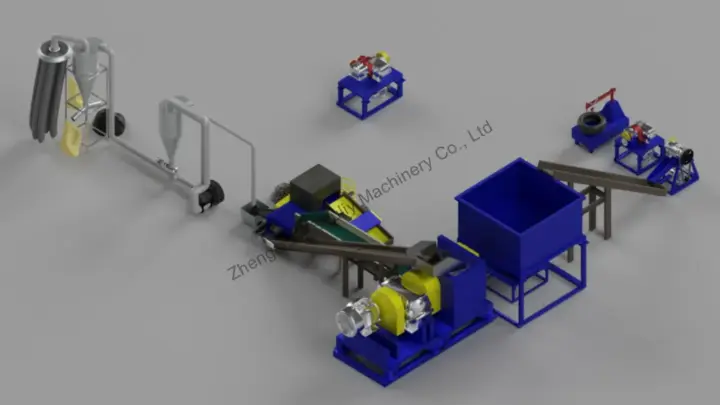

Our semi-automatic tire recycling production line is used to process waste tires with a diameter of ≤1200mm. This production line is renowned for its simple operation, low investment costs, and easy maintenance. It efficiently processes waste tires into 5–40 mesh rubber powder, enabling the recycling of rubber resources.

The tire recycling machine is widely applicable to various types of waste tires, including car tires, truck tires, and construction tires. It is an ideal choice for tire recycling enterprises, small and medium-sized processing plants, and entrepreneurial investors.

Semi-automatic rubber powder machine production process

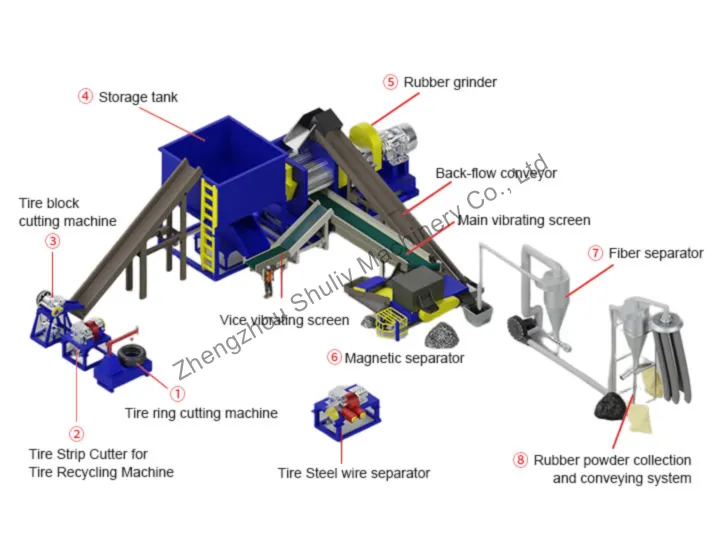

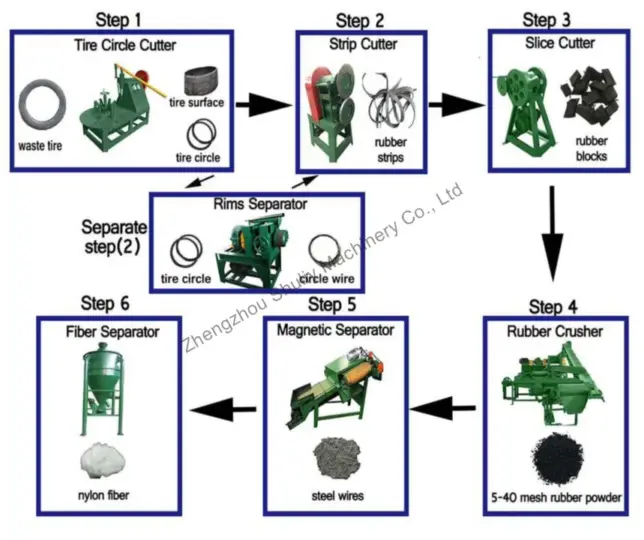

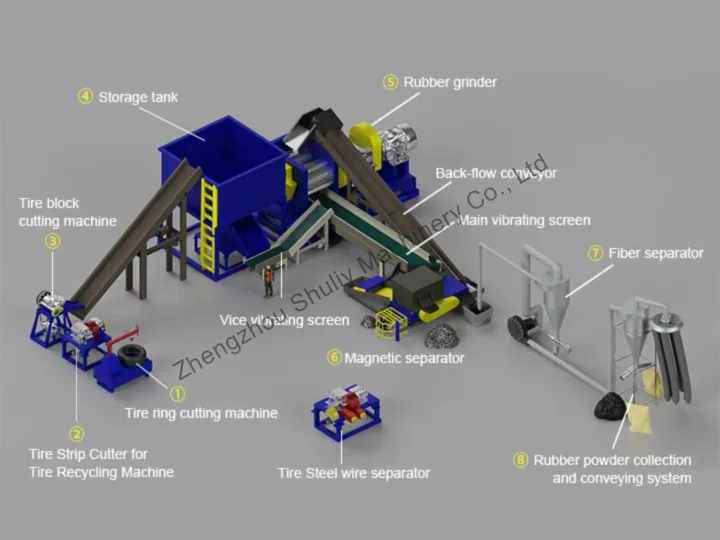

The entire tire recycling production line primarily consists of the following processes: tire sidewall removal→tire strip cutting→tire block cutting→rubber powder grinding & screening→magnetic separation→fiber separating. As shown below:

Each step features matching equipment, meticulously optimized to ensure the efficient separation of rubber from steel wires and a uniform particle size of the final product. Below are the specific devices for each step.

Step 1: Tire ring cutting machine

It’s used to remove the steel bead rings from both sides of the tire, preparing it for subsequent cutting and shredding. The bead removal process is stable and safe, effectively protecting subsequent cutting tools.

Step 2: Tire strip cutting machine

It slices de-beaded tires into uniform rubber strips with adjustable width (approx. 3–5cm), providing appropriately sized raw material for the block-cutting stage.

Step 3: Tire block cutter

The machine cuts rubber strips into small blocks, approximately 3×5cm, for efficient processing in the subsequent grinding stage. Features high-strength alloy steel blades with excellent wear resistance and extended service life.

Step 4: Rubber powder grinding machine & screening system & magnetic separator

The rubber grinder is the core equipment of the entire tire recycling production line, further pulverizing rubber blocks into rubber powder with a mesh size of 5–40. Featuring a dual-roll design, it ensures uniform crushing, high output, and low energy consumption.

The screen classifies and screens crushed rubber particles to ensure consistent particle size and stable quality. Screen specifications can be adjusted according to customer requirements.

Shuliy magnetic separator thoroughly separates steel wire components from rubber, enhancing the purity of the final rubber powder. This enables direct use in recycled rubber products or rubber asphalt.

Step 6: Fiber separation machine

This machine is optional, separating fine fibers from rubber powder in the waste tire recycling line, particularly for nylon tires. If the customer does not require nylon fiber removal, this machine can be omitted.

Advantages of Shuliy semi-automatic tire recycling production line

- Wide applicability: This tire recycling line processes tires with diameters ≤1200mm, including car and truck tires.

- High efficiency & energy savings: Optimized blade structure and motor power ensure high output with low energy consumption.

- Thorough separation: It achieves an over 98% separation rate between steel wires and rubber, yielding high-purity rubber powder.

- Simple operation: Semi-automated control allows operation by general workers.

- Fast return on investment: The overall cost of the tire recycling machine line is lower than that of fully automated equipment, making it suitable for small and medium-sized investors.

Applications of tire recycling machine line

This rubber powder machine line turns waste tyre into rubber powder, and the finished rubber powder is widely used in recycled rubber production, rubber tiles and track materials, rubber tiles and track materials, manufacturing of shock absorbers and seals, asphalt modification materials, etc.

This production line helps customers transform waste tires into high-value-added products, achieving a win-win outcome for resource regeneration and environmental protection.

Why choose Shuliy semi-automatic waste tire recycling production line?

- One-stop tire recycling solution: Complete configuration from cutting tire rings, strips, and chunks to grinding, screening, and magnetic separation.

- Customizable design: Tailored tire recycling production line solutions based on customer output requirements (500kg/h–2000kg/h).

- Comprehensive after-sales support: Installation guidance, operator training, and technical assistance ensure rapid production commencement.

- Extensive international project experience: Equipment exported to Kenya, Nigeria, Uzbekistan, Peru, the Philippines, and more, with positive customer feedback.

Contact us now for a quote!

Shuliy Semi-Automatic Rubber Powder Machines offer exceptional value, user-friendly operation, and stable performance, making them the ideal choice for small to medium-sized tire recycling plants. Whether you’re a newcomer to the scrap tire recycling industry or an existing processor looking to expand production, we deliver tailored solutions.

Contact us today for detailed quotes and on-site video demonstrations to turn scrap tires into valuable resources!