Our metal crusher machine is a specialized shredding machine designed for processing scrap metal, capable of rapidly reducing scrap steel, scrap iron, scrap aluminum, paint cans, beverage cans, circuit boards, and similar materials to finished sizes of 3–10 cm. The finished product shape varies depending on material thickness, appearing as spherical (thin material) or segmented (thick material).

It has a capacity of 600-18000kg per hour, ideal for metal smelting, metal recycling, and steel enterprises. This aluminum can crusher is commonly used for crushing, sorting, and recycling scrap aluminum, thermal break aluminum, and color-coated steel roofing sheets.

Advantages of scrap metal crusher

- Adopting hammers and sieve plants inside the machine, it can process 600-18000 kg of scrap per hour, which is highly efficient.

- It’s capable of handling both thin materials (like aluminum cans, oil drums) and thick materials (like bicycle frames), compatible with various scrap metal types.

- This metal crusher machine is highly automatic, which can be equipped with conveyors and magnetic separators for automated feeding, crushing, and sorting, reducing labor costs.

- Crushed material typically measures 3–10 cm, suitable for direct smelting or sale.

- Shuliy metal shredder has a compact design with durable wear parts, ideal for extended continuous operation.

Technical parameters of aluminum can crusher

Different models of metal crusher machines feature varying processing capacities and power configurations. Refer to the table below for more details.

| Model | Capacity(kg/h) | Power(kW) | Rotational speed(r/min) | Dimensions(mm) |

| BDL-600 | 600-800 | 18.5–22 | 860 | 2000 × 1200 × 1900 |

| BDL-800 | 800-1000 | 30–37 | 860 | 2200 × 1500 × 2200 |

| BDL-1000 | 2500-3500 | 55–75 | 860 | 2800 × 1900 × 3100 |

| BDL-1300 | 3500-5000 | 90–110 | 750 | 3500 × 2100 × 3800 |

| BDL-1600 | 4000-8000 | 110 × 2 | 750 | 4400 × 2500 × 4200 |

| BDL-1800 | 8000-12000 | 160 × 2 | 650 | 4700 × 2900 × 4500 |

| BDL-2000 | 10000-18000 | 220 × 2 | 650 | 4700 × 2900 × 4500 |

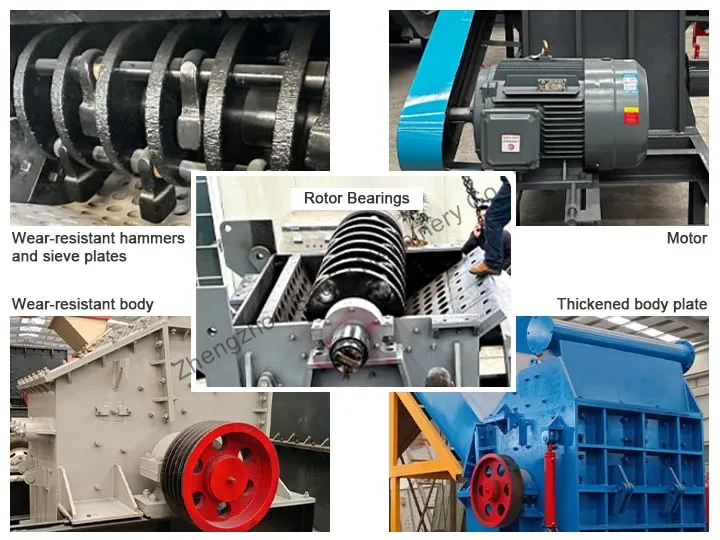

Structure of metal crushing machine

This aluminum can shredder is composed of multiple structural components to ensure efficient and stable operation, including:

| Machine part name | Function |

| Feed inlet/feed conveyor | Enable uniform and continuous material feeding. |

| Crushing chamber | Constructed with high-strength steel plates for impact and wear resistance. |

| Hammer system | Deliver a powerful impact or tearing force to metal, serving as the core crushing component. |

| Motor and transmission system | Provide robust power to guarantee stable operation. |

| Bottom screen | Control the size of the finished product. |

| Magnetic separator (Optional) | Automatically separate ferrous metals after crushing. |

| Discharge conveyor | Automatically output the crushed finished product. |

How does this metal crusher machine work?

This metal shredder employs high-speed rotating hammers to impact, tear, and compress scrap metal, causing it to rapidly deform and break apart. The specific workflow is as follows:

- Material is fed into the crushing chamber via conveyor or manually.

- In the crushing chamber, our hammers impact, tear, and compress the scrap metal, rapidly deforming and crushing it.

- The crushed material falls through the screen; oversized pieces are further processed within the chamber.

- Finished products are discharged via the output conveyor, while a magnetic separator automatically separates ferrous metals from other materials.

The entire process features high automation and exceptional efficiency.

Applications of metal can crusher

Our metal crusher machine is widely used in the following industries:

- Scrap metal recycling stations: Processing mixed metals, scrap iron, and scrap aluminum.

- Appliance dismantling plants: Shredding motor housings, aluminum casings, iron components, etc.

- Steel smelting plants: Providing standardized shredded sizes for furnace feedstock.

- PCB recycling enterprises: Pre-processing shredding of printed circuit boards.

- Automotive dismantling plants: Processing thin sheet metal and aluminum components from vehicle bodies.

- Thermal break aluminum production line: Shredding aluminum extrusions for subsequent sorting.

Applicable materials:

- Flattened car bodies, disassembled parts of car bodies, etc.

- Thin and light materials with a density of no more than 1t/m³ that have been cut or packaged

- Household appliances: such as old washing machines, refrigerators, air conditioners, color steel tiles, etc.

- Waste motorcycles, electric vehicles, bicycles, and car body parts

- Waste cans, paint buckets, and waste aluminum (excluding liquids, paint, etc.)

- Waste iron sheets, scrap steel, scrap iron, old metal, thermal break aluminum doors and windows, radiators, etc

It has a wide range of applications and serves as the core equipment in the scrap metal recycling industry.

What’s Shuliy metal crusher price?

The price of Shuliy scrap metal crusher depends on the following factors:

- Equipment model and output capacity (significant price difference between 500kg/h and 5t/h models)

- Whether integrated into a complete production line (conveyor, magnetic separator)

- Material type and crushing difficulty

- Custom feed inlet configuration

- Transportation and voltage requirement

Typically, the metal crusher price ranges from several thousand to tens of thousands of US dollars. We will provide the most suitable model and quotation based on your material type, production capacity, and budget.

Why is a metal crusher machine worth investing in?

Investing in the metal shredder delivers significant economic benefits:

- Enhance metal recycling value: Shredded materials are easier to sort, achieve higher purity, and command better prices.

- Reduce labor costs: Automated equipment minimizes manual labor requirements.

- Increase output and expand revenue: High hourly throughput supports large-scale operations.

- Long equipment lifespan and low maintenance costs: Ideal for long-term investment.

- Environmental compliance: It helps businesses meet recycling standards while enhancing social value.

Thus, our heavy-duty aluminum can crusher serves as core equipment in the scrap metal industry, offering rapid return on investment and high profitability.

FAQ of scrap metal crusher machine

What metals can be crushed?

Scrap iron, scrap steel, aluminum products, beverage cans, paint cans, auto parts, motor housings, etc. can all be processed.

What is the size of the shredded output?

3–10cm, adjustable based on screen size.

Is a complete production line required?

We recommend configuring a conveyor belt + magnetic separator to enhance efficiency and reduce labor.

What is the lifespan of hammerheads?

Depending on material hardness, they typically last over 6 months and can be replaced quickly.

Can on-site testing be arranged?

We can provide video demonstrations or arrange for customers to test materials at our factory.

Is voltage customization available?

Custom voltages are supported, including 380V, 220V, 415V, 440V, etc.