Shuliy eddy current separator(copper-aluminum separator or non-ferrous metal eddy current separator) efficiently separates non-magnetic metals (such as aluminum and copper) from non-metallic materials within waste streams. Utilizing the physical properties of metals, it can sort them into 4 kinds: aluminum, copper+iron, plastic and impurities.

This copper-aluminum separator has a capacity of 4-15 tons per hour and is suitable for scrap with particle sizes of 2mm or larger. It’s widely used in industries such as scrap metal recycling, electronic waste processing, and municipal solid waste recycling. If you’re interested, welcome to contact us at any time for more!

How does an eddy current separator(ECS) work?

Our eddy current aluminum separator utilizes the principle of eddy currents induced in metals within a magnetic field to sort materials. Its magnetic roller can sort larger or smaller materials by controlling forward and reverse rotation.

- Feeding materials

- Mixed waste materials (such as aluminum, copper, plastic, wood chips, etc.) enter the eddy current separation zone via a belt conveyor.

- High-speed rotating magnetic roller

- High-speed permanent magnet rollers at the rear of the equipment begin operation, generating a strong and rapidly fluctuating alternating magnetic field. It’s the core principle of eddy current separation.

- Inducing eddy currents in the magnetic field

- When non-magnetic metals (e.g., aluminum, copper) enter the magnetic field zone, eddy currents are generated within the metal.

- These eddy currents produce a magnetic force opposing the magnetic field direction. This repulsive force causes the metal to instantly bounce or jump off its original trajectory.

- Automatic separation of metals and mon-metals

- Metals affected by the repulsive force are ejected into the metal collection areas of the equipment.

- Non-conductive materials (such as plastic, paper, wood chips) do not generate eddy currents and continue falling along their normal path.

- Sorting into different outlets

- The sorted metals and non-metals fall into separate collection ports, achieving precise and efficient separation, significantly enhancing metal purity.

Advantages of eddy current separator machine

- Featuring an intelligent touch-control cabinet with variable frequency control for smoother operation, it runs more reliably and extends equipment lifespan.

- You can operate it simply, just one-touch start, very simple.

- This machine can process 4-15 tons per hour, which is highly efficient.

- It precisely sorts waste materials with particle sizes above 2mm, widely applied in separating metals, electronic waste, plastics, and other materials.

- Adopting high-quality neodymium iron boron permanent magnet rollers and imported bearings, the machine is capable of long-term, high-efficiency operation.

- The magnetic roller employs an effective magnetic system protection mechanism to prevent the magnetic system from detaching during high-speed operation.

Technical parameters of copper-aluminum separator

The following table lists the most common models of eddy current separators in our aluminum recycling lines. From this table, you can find information such as machine output, dimensions, and weight. For further details, please contact us.

| Model | Capacity(t/h) | Belt width(mm) | Rotary speed(r/min) | Power(kw) | Weight(kg) | Dimensions(mm) |

| 600 | 4-6 | 650 | 0-3000 | 4.0+0.75 | 1400 | 2980 X 1883 X 1210 |

| 800 | 6-10 | 850 | 0-3000 | 5.5+1.1 | 1800 | 2980 X 2033 X 1210 |

| 1000 | 10-12 | 1050 | 0-3000 | 7.5+1.5 | 2200 | 2980 X 2233 X 1210 |

| 1200 | 12-15 | 1250 | 0-3000 | 11+2.2 | 2400 | 2980 X 2433 X 1210 |

Applications of eddy current non-ferrous metal separator

Our eddy current separator is widely used in the following industries:

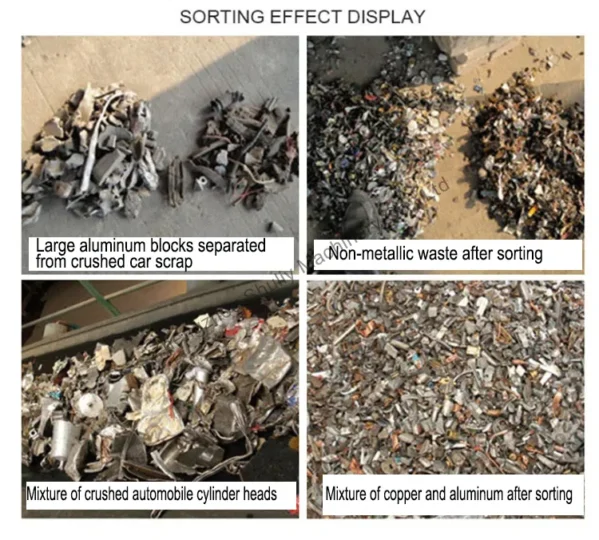

- Scrap metal recycling: Separating non-ferrous metals such as aluminum and copper.

- Electronic waste processing: Separating non-ferrous metals like copper and aluminum from circuit boards.

- Municipal solid waste treatment: Isolating metallic components from waste.

- Recycling of waste plastic doors and windows: Extracting metal parts from discarded plastic doors and windows.

- Boiler bottom ash and industrial scrap recycling: Sorting various mixed metal waste streams.

- End-of-life vehicle recycling: Separating non-ferrous metals from dismantled scrap vehicles.

What’s Shuliy eddy current separator price?

This eddy current sorting machine depends on the model, processing capacity, configuration, and other custom requirements. Generally, prices range from several thousand to tens of thousands of dollars. Specific quotations can be provided based on customer needs and equipment configuration. We offer cost-effective equipment and provide global shipping, installation, and commissioning services to our customers.

Comparison: Manual sorting VS. Shuliy eddy current separator machine

Compared to manual sorting, the eddy current separation method features:

- Faster sorting speed

- Higher sorting accuracy

- Simple operation, saving labor

- Automated assembly line operation

- Wide range of particle sizes for sorting

FAQ of eddy current non ferrous separator

What types of waste materials are suitable for eddy current separators?

Municipal solid waste, electronic waste, industrial waste, scrap aluminum, scrap copper, waste plastics, and similar materials.

What is the particle size range for processing by eddy current sorting machines?

This equipment is suitable for sorting materials larger than 2mm.

How does it enhance metal recovery rates?

Through efficient magnetic field separation, this iron-aluminum separator precisely separates metals from non-metals, ensuring metal purity and increasing recycling value.

What is the price of an eddy current separator?

Its price depends on factors such as model, processing capacity, and customization requirements. Please contact us for a specific quote.

Get a quote now!

Contact us for the latest pricing and detailed configuration plans for eddy current separators. We not only supply standalone sorting equipment but also provide complete metal recycling production lines tailored to your needs, including

- Metal shredder

- Metal crusher

- Magnetic separator

- Conveying system

This helps you achieve a more efficient and intelligent metal sorting and recycling process. Inquire now to get the recycling solution best suited for your operations!