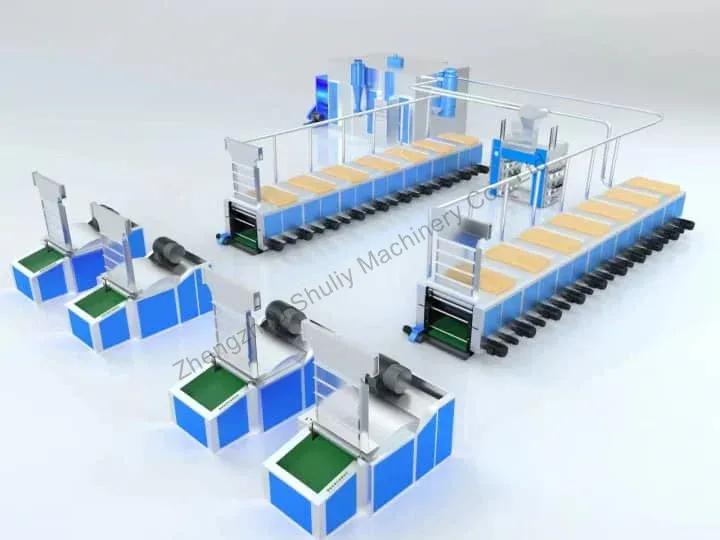

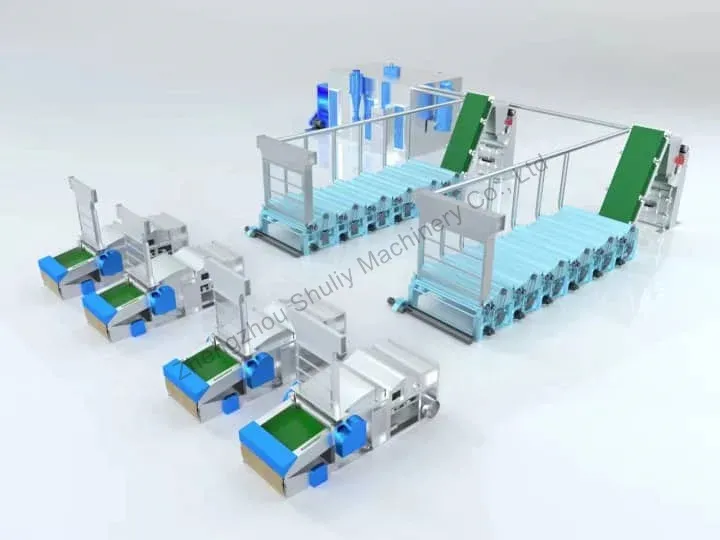

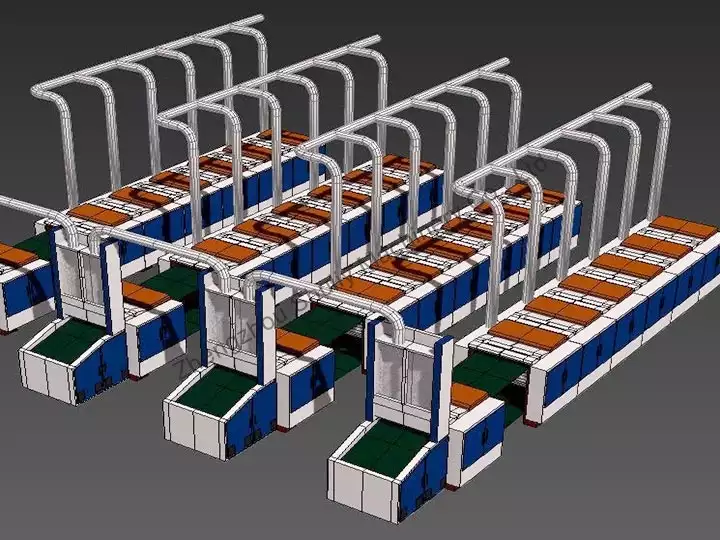

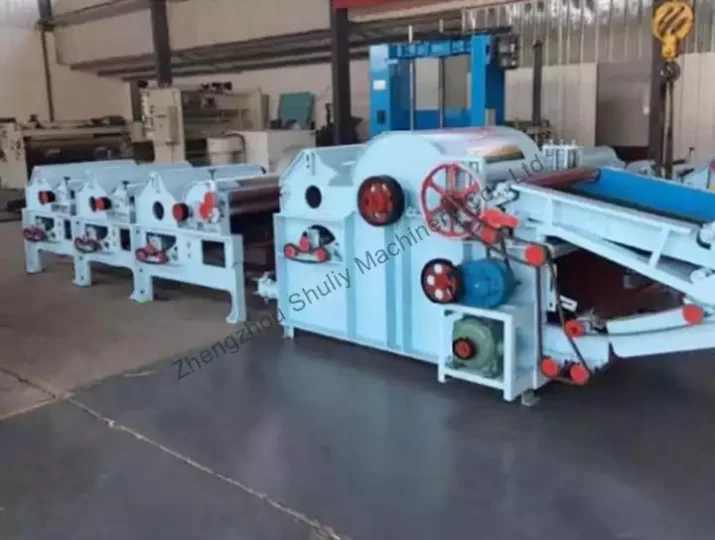

Shuliy textile waste recycling machine is a combination of fiber waste shredder, opener and cleaner to achieve efficient processing of used textiles. It has a capacity of 250-350kg/h.

This recycling line can use the feeder(stocking materials to adapt to line processing) and dust collection device(collet dust during textile waste recycling) for better handling of waste fiber.

Features of this line include efficient clean-up, resource sustainability, waste reduction and improved disposal efficiency. It helps to drive the environmental and economic benefits of waste management.

It is an unbeatable machine for industries related to fibre recycling and processing.

Look at the below video, which helps you easily understand how to recycle textile fiber waste.

Characteristics of textile waste recycling machine for sale

- Process of textile with shredding→opening→carding. This textile recycling machine line handles waste textiles step by step. This ensures efficient waste textiles recycling.

- Handle 250-350kg of waste per hour. Compared with the traditional method, Shuliy waste textile recycling machine improves the textile handling efficiency.

- Efficient cleaning. The function of the fiber opener and cleaner is to clean and card the fibres, remove impurities and ensure improved fiber quality.

- Resource sustainability. By converting waste textiles into reusable raw materials, the textile waste recycling machine helps reduce resource wastage.

- Also, it increases the sustainability of the textile industry.

- Waste reduction. Textile waste is waste itself. Through this line, the waste that exists can be maximized.

- At the same time, this reduces the environmental burden and promotes sustainable waste management.

- Customizable voltage, power, configuration, etc. According to your needs, we can customize the machine voltage and power, collocation(like a 2-roller opener with a 6-roller cleaner), etc.

How do you recycle textile waste?

Learning the features of textile waste recycling machines, now we’ll introduce the steps of processing waste textiles.

Collection and sorting

Firstly, collect and sort waste textiles. This may include used clothing, bedding, towels, etc. You can classify them according to type and texture.

Inspection and removal of contaminants

Before recycling, you should check the waste materials to remove possible contaminants such as metals, plastics, zips, etc.

Shredding

Then feed the scrap to the shredding machine. Its function is to cut waste into small pieces or fragments.

Opening

Then, to remove impurities and clean the fibres, you should send shredded fabrics into the cotton opener.

Carding

Next, for getting materials that are more uniform and suitable for remanufacturing, you feed fibres into a cleaner. The fabrics will be further cleaned, carded, and refined.

Processed textile reuse

Fibers treated in the above steps can be used to make new textiles, fabrics and products.

What machines are used in textile recycling?

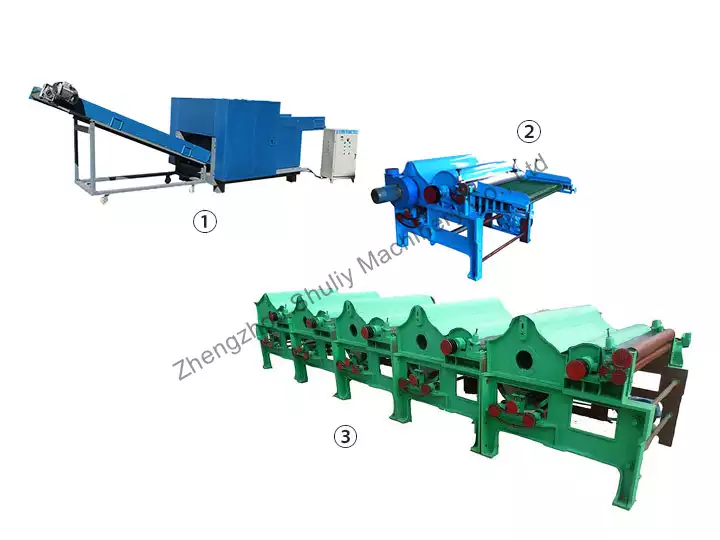

After knowing the steps of textile waste recycling, now let’s together see the equipment used in the textile recycling machine line.

This machine is first used in textile waste recycling machines. It cuts waste fabrics into small pieces, with a capacity of 500-3000kg/h.

It can cut fibers with a size of 5-300mm and a thickness of 20-60mm.

After shredding, the cotton opener is used.

It mainly breaks up fibres, making them looser and more processable. It has an output of 200-300kg/h.

This helps to remove impurities and clean fibres from textiles, improving quality and reusability.

Finally, the carding machine is used to further clean and card the fibres. It has a capacity of 150-250kg/h.

The machine makes fibres more uniform and ready for use in remanufacturing textile processes.

Ways to avoid dust during textile waste recycling

In the process of textile waste recycling, dust is inevitably generated. In order to avoid the generation and spread of dust, effective dust removal equipment is required.

We equip the dust extraction system in the working area.

It can effectively trap and remove dust generated, preventing it from spreading to other areas. Also, it helps to reduce dust in the recycling process.

Can you make money from textile recycling?

When it comes to textile waste recycling, profitability can be achieved in many ways. As a customer, key points of interest to you include:

- Procurement costs of used textiles

- Cost-effectiveness of the recycling machine

- Profit potential of remanufacturing and remarketing

- Market opportunities associated with sustainability

Shuliy textile waste recycling machine can help you save purchasing costs, efficient recycling processes, and sell finished products at a profit. By using our machine, you can turn textile recycling into a profitable business.

Thus, our textile recycling machine is a good choice for those who want to profit from textile waste. If interested, get in touch with us at any time for more details!

Shuliy: professional waste textile recycling machine manufacturer & supplier

Shuliy is a professional manufacturer and supplier of garment waste recycling machines. We have the following advantages:

- Various recycling equipment. Our textile recycling machinery includes the fiber shredder, opener, cleaner, etc.

- Excellent machine quality. During the machine manufacturing process, our factory carries out strict quality control to ensure the machine’s quality.

- Customized solutions. We have professional sales teams. Whether you are a business or an individual, Shuliy can provide customized solutions to meet your needs.

Get in touch for textile waste recycling machine price!

Want to make profits with textile waste recycling machines? Please provide your specific requirements, like capacity, budget, factory space, etc. We can provide you with the exact waste textile recycling machine price.

You can contact us at any time and we will reply to your inquiry as soon as possible.