Shuliy rubber steel wire separator is used to crush tire pieces into rubber granules(10-16mm) and separate steel wire from rubber tire granules. Its capacity ranges from 800-5000kg/h. This equipment typically forms part of a complete tire recycling production line alongside tire shredder, rubber grinding mill, magnetic separator, and dust collection system, serving as a vital component in the deep recycling and reuse of waste tires.

Advantages of rubber steel wire separation machine

- Through crushing and magnetic separation, the steel wire separation rate can reach over 99%, ensuring the purity of rubber granules.

- The main machine(rubber crusher) adopts an alloy cutting tool design, which can run continuously for a long time with stable output.

- This rubber steel wire separator can configure a nylon dust removal system to meet environmental requirements and be suitable for factory production.

- It can operate independently or form an integrated production line with a tire shredder and a grinding machine to achieve automatic tire recycling operation.

Technical parameters of rubber tire steel wire separator machine

As a professional recycling equipment manufacturer and supplier, we have different models available to meet your production demands. Please refer to the following for detailed information. We will recommend suitable models based on your tire size, production volume, and investment budget.

| Model | 600 | 800 | 1200 | 1500 | 1800 |

| Output(10-16mm) | 800kg/h | 1000-1500kg/h | 2000kg/h | 3000kg/h | 5000kg/h |

| Feeding conveyor belt | Power: 1.5kw Weight: 600kg Size: 7.2*0.6*2m | Power: 1.5kw Weight: 800kg Size: 7.2*0.8*2.4m | Power: 1.5kw Weight: 1000kg Size: 7.2*1.2*3.3m | Power: 3kw Weight: 1000kg Size: 7.2*1.2*3.3m | Power: 3kw Weight: 1000kg Size: 7.2*1.2*3.3m |

| Main machine | Power: 45kw Weight: 6500kg Size: 3.6*1.6*2.4m | Power: 75kw Weight: 9800kg Size: 4.2*2*3m | Power: 110kw Weight: 14700kg Size: 5*2.2*3.8m | Power: 132kw Weight: 17500kg Size: 5.5*2.2*3.8m | Power: 160kw Weight: 21300kg Size: 6*2.2*3.8m |

| Discharging conveyor belt | Power: 1.5kw Weight: 600kg Size: 7.2*0.6*2m | Power: 1.5kw Weight: 800kg Size: 7.2*0.8*2.4m | Power: 1.5kw Weight: 1000kg Size: 7.2*1.2*3.3m | Power: 3kw Weight: 1000kg Size: 7.2*1.2*3.3m | Power: 3kw Weight: 1000kg Size: 7.2*1.2*3.3m |

| Magnetic separator | Power: 0.75kw Weight: 200kg Size: 1.2*0.6*1m | Power: 0.75kw Weight: 300kg Size: 1.3*0.8*1m | Power: 0.75kw Weight: 400kg Size: 1.3*1.2*1m | Power: 1.5kw Weight: 400kg Size: 1.3*1.2*1m | Power: 1.5kw Weight: 400kg Size: 1.3*1.2*1m |

| Nylon dusting collection system | Power: 5.5kw Weight: 300kg Size: 1.6*1.6*4.2m | Power: 7.5kw Weight: 350kg Size: 1.6*1.9*4.2m | Power: 11kw Weight: 400kg Size: 1.9*1.9*4.2m | Power: 11kw Weight: 400kg Size: 1.9*1.9*4.2m | Power: 11kw Weight: 400kg Size: 1.9*1.9*4.2m |

| Overall footprint | 16*7*4.2m | 16*7*4.2m | 16*7*4.2m | 16*8*4.2m | 16*7*4.2m |

Structure of rubber wire separating machine

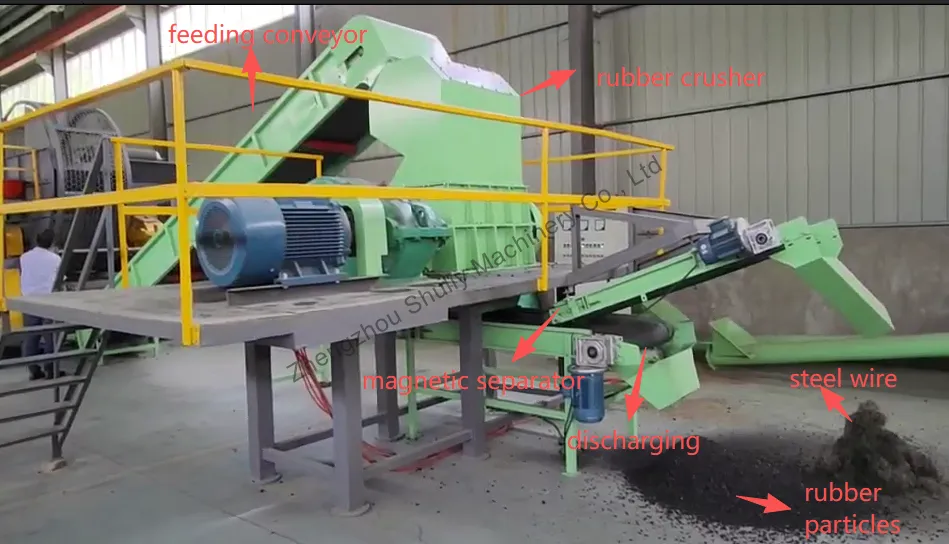

The entire rubber steel wire separator mainly includes:

- Feeding conveyor: Evenly feed the tire pieces into the main machine to ensure continuous and stable feeding.

- Rubber tire crusher: The core component uses alloy cutting tools to rotate at high speed, crushing tire pieces to the desired particle size.

- Discharging conveyor: Achieve continuous automated discharge.

- Magnetic separator: Separate steel wires mixed in rubber.

- Nylon dust removal system: Effectively separate nylon fibers from rubber while maintaining a clean working environment.

The entire system is designed to be compact and highly automated, suitable for large-scale, continuous production.

Why choose Shuliy rubber tyre steel wire removal machine?

Shuliy is a professional manufacturer with over 20 years of experience in tire recycling equipment. We offer:

- One-stop solution to wate rire recycling: We can provide customers with one-stop configurations such as tire shredder, rubber grinder, packaging machine, etc.

- Customization service: Shuliy supports OEM customization of different power, tool materials, discharge sizes, and control systems.

- Quality assurance: The core components are made of thickened steel plates and high-strength bearings to ensure the stability and service life of the rubber steel wire separator.

- Experienced in overseas projects: Our machines have been exported to over 20 countries including Australia, Saudi Arabia, Chile, Morocco, etc., highly trusted by customers.

- On-site testing and factory visit services: In order to strengthen customers’ trust on Shuliy’s machines, we conduct on-site testing and welcome customers to visit our factory before placing an order.

You only need to provide the type of tire and target production capacity, and we can design the most suitable recycling line solution for you.

What’s the price of rubber steel wire separator?

The equipment price varies depending on the model, configuration, and whether it includes dust removal. Generally speaking, the higher the configuration, the more expensive the machine is. If you need detailed quotations and export cases, please contact us for a one-to-one customized solution and production video display.

What rubber tire recycling plants is this equipment suitable for?

This rubber steel wire separator is widely used in:

- Waste tire recycling and processing plant

- Recycled rubber product manufacturing enterprises

- Rubber floor tiles, running tracks, shoe soles, shock absorbers and other industries

If you are looking for an efficient and stable rubber steel wire separator, Shuliy provides full process support from solution design, equipment manufacturing to after-sales service, helping you quickly enter production and improve tire recycling efficiency. Contact us immediately for detailed quotations, export cases, and project plans to embark on your journey of recycling waste tires.