Shuliy rubber tire shredder crushes used car tires, truck tires, disintegrated OTR tires, etc., into 50-100 rubber blocks for subsequent separation, crushing and reuse. It has a processing capacity of 2-20t per hour.

For a fully automatic tire processing line, this tire shredder equipment can work with the belt conveyor, magnetic separator, steel wire separator, etc., supporting the whole line configuration. Its finished products are the raw materials for producing rubber granules, rubber powder, and other products. If want to know more details, welcome to contact us at any time!

Applicable tire crushed by scrap tyre shredder

Our rubber tyre shredder machine can be used to process:

- Car tires, light truck tires

- OTR tires (need to be pre-cut)

- Containing steel wire, nylon tires

Some common tires are exemplified above. If you are not sure whether your tires can be shredded by our indutrial tire shredding machine, you can ask us directly!

Advantages of rubber tire shredder machine

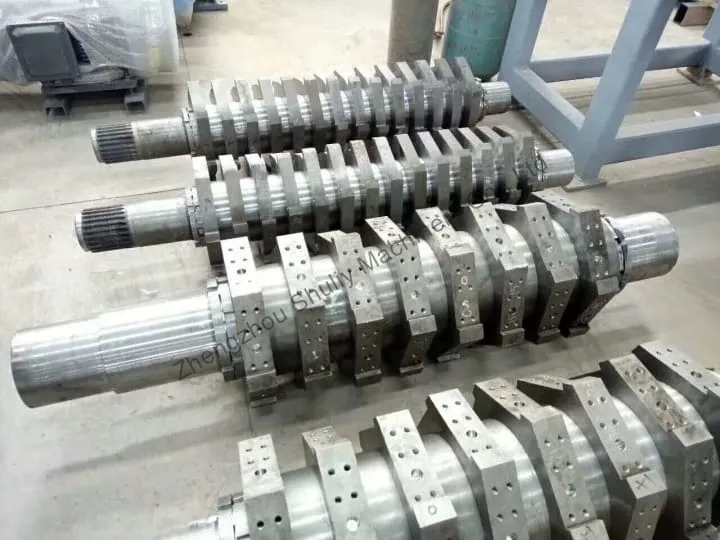

- Dual-axis knife roller design: strong tearing tires, automatic reverse to prevent jamming.

- Alloy composite blades: super wear-resistant, support multiple repairs and grinding use, suitable for long-term industrialized use.

- Adjustable discharging size: meet different rubber powder/granules crushing needs through different screen sizes.

- Various waste tyre processing: truck tires, OTR tires, big car tires, bus tires, etc., can be shredded for recycling.

- Powerful handling capacity: this tire crusher has an output of 2-20t/h, which is highly efficient.

Technical parameters of industrial tire shredder

The following are five types of tyre crushers provided by Shuliy, ranging from SL-900 to SL-1800. The capacities range from 2 to 20 tons/h, to meet the different production capacity requirements of small, medium, and large-scale factories with varying capacities.

| Model | SL-900 | SL-1200 | SL-1500 | SL-1800 |

| Power | 64.5kw | 157kw | 188.5kw | 328.5kw |

| Capacity | 2t/h | 5-6t/h | 8-10t/h | 15-20t/h |

| Size of main machine | 4*2.2*2.8m | 5*2.6*3.2m | 20*10*3.5m | 20*12*4m |

| Weight | 10t | 15.8t | 18.6t | 26t |

| Occupying space | 9*5*2.8m | 10*6*3.2 m | 20*10*3.5 m | 20*12*4 m |

| Feeding size | <900mm | <1200mm | <1200mm | <1400mm |

| Discharging size | 50mm | 60mm | 75mm | 100mm |

| Blade diameter | 360mm | 510mm | 580mm | 650mm |

| Blade thickness | 50mm | 60mm | 75mm | 100mm |

| Blade quantity | 16pcs | 18pcs | 20pcs | 18pcs |

| Blade material | Composite alloy knife | Composite alloy knife | Composite alloy knife | Composite alloy knife |

| Conveyor belt size | 7200*950mm | 7200*1350mm | 7200*1350mm | 7200*1550mm |

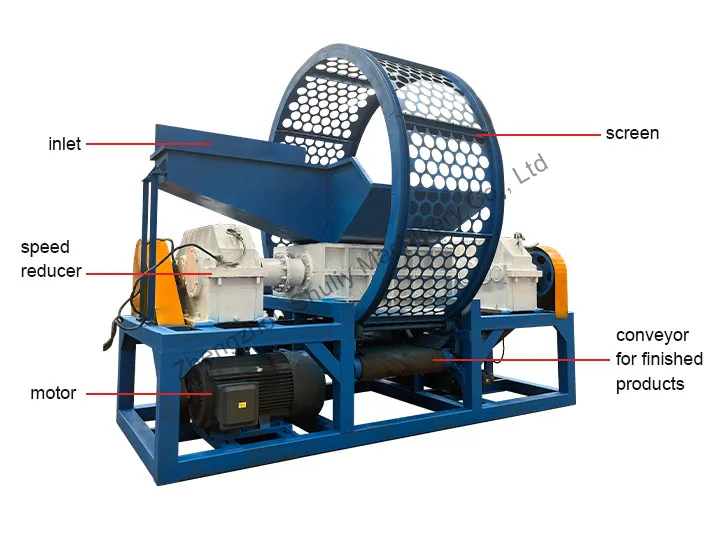

Shuliy OTR tire shredder structure and working principle

Our rubber tire shredder machine mainly consists of inlet, screen, speed reducer, motor, conveyor belt, etc.

When working, the tires are sent into the shredding chamber by the conveyor belt, and the dual-axis knife rollers rotate in opposite directions to form a strong shear force, which tears the tires into blocks repeatedly.

What’s the rubber tire shredder machine price?

The price of a car tire shredder varies according to the model, configuration, motor power, blade thickness and other factors. For example, the price of SL-900 is definitely cheaper than SL-1800. Blade material, whether supporting the whole line (such as steel wire separation, belt conveyor), will also affect the total price.

We provide free selection service, and can give you a detailed quotation list according to your processing capacity, site, etc. Welcome to consult us anytime to get a real-time quotation and customer site reference program.

Why choose Shuliy rubber tire shredder for recycling?

Shuliy tire recycling equipment is well-received by customers worldwide for the following reasons:

- Factory direct supply and reasonable price: self-developed and manufactured without middlemen.

- Mature and stable equipment: it has been exported to more than 30 countries with good customer feedback.

- Complete line support: it can be matched with tire de-beading, cutting, steel wire separating and rubber powder production line to form a closed-loop process.

- Perfect service: support overseas debugging, operation training and fast response for spare parts.

- Strong customization ability: machine structure and program control system can be customized according to different tire sizes, materials and voltages.

FAQ of car and truck tire shredder

Can it process tires with steel wires?

Yes, there is no need to remove the steel wire in advance. It can be used with the subsequent steel wire separation equipment.

How long does the blade last?

It is made of alloy steel, can normally be used for more than 5000 tons of tires. It supports repeated grinding and easy replacement.

Does it support voltage customization?

We can customize international voltages such as 3-phase 380V/415V/440V to meet the requirements of different countries.

Is the equipment noisy? Is it suitable for the city plant?

It is a low-speed shearing rubber tire shredder. The noise is within the controllable range, and the factory can be equipped with a sound insulation device.

Is it complicated to operate? Do you need professional staff?

Simple operation. We send the machine with video instructions and a manual, providing remote training.

Do you provide a complete tire recycling line?

We can provide a one-stop solution from tire debeading, cutting, shredding, rubber powder grinder machine and so on.

Welcome to contact us for a detailed quotation, configuration plan and customer site video! We will provide the most suitable tire recycling program according to your site, power, production and budget.