Egg cartons, as an important packaging for eggs, not only protect eggs effectively, but also improve the safety of transportation and storage. Many customers are concerned with key issues such as the production process, equipment required and costs when planning to produce egg cartons. This article will detail the egg carton production process and answer the core questions of our customers.

Main steps in egg carton production

The egg carton production process mainly includes raw material preparation, pulping, molding, drying, pressing and packaging. Each step directly affects the quality and production efficiency of egg cartons.

Raw material preparation

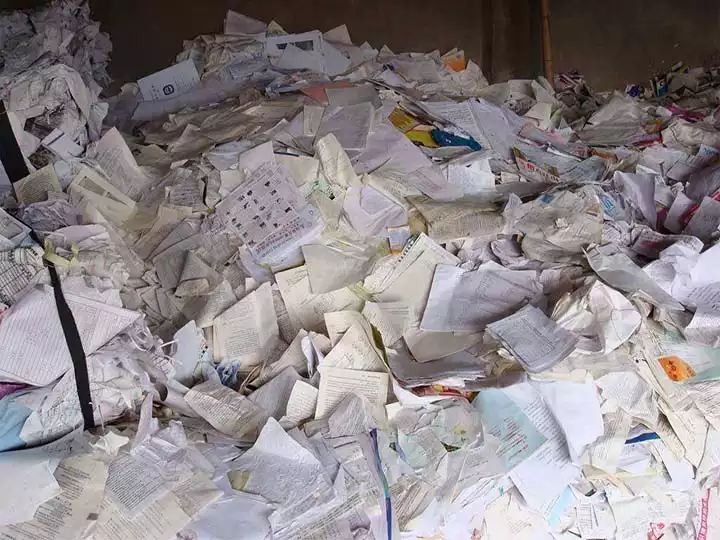

The main raw material of egg carton is waste paper, such as old newspapers, cardboard boxes and so on. These waste papers are recycled and crushed to form pulp.

Pulping

Waste paper is stirred by hydraulic pulper and mixed with appropriate amount of water to form uniform pulp. This process can add colors, etc. to enhance the beauty of the egg carton.

Forming

Through the pulp forming machine, the pulp is adsorbed onto the egg carton molds to form the basic shape of the egg carton.

Drying

After molding, the wet egg carton has high moisture content and needs to be dried by natural drying or hot air dryer. The metal dryer is the best choice for high output production, with fast drying speed and stable effect.

Pressing and packing

After high temperature pressing, the surface of the egg box is smoother and stronger, and finally it is stacked and packed, ready for sale or transportation.

Customer’s top concerns on egg carton production

When choosing egg carton production equipment and planning a factory, customers often focus on the following questions:

What is the output of the egg carton machine?

The output of our egg crate machine varies(1000-7000pcs/h) according to different models. Small egg carton machines are suitable for companies with small daily demand, while fully automated egg carton production lines are suitable for large-scale production.

What is the investment cost of the equipment?

The investment cost of egg carton production line depends on the production capacity and the degree of automation. Small line is relatively inexpensive and suitable for first-time entrepreneurs, while large fully automatic production lines have higher investment but lower long-term running costs and higher efficiency.

How to choose the right drying method?

Small-scale paper tray production can use natural drying methods, but this is greatly affected by the weather. For large-scale production, metal dryers are recommended for fast drying, energy savings, and environmental protection, which can ensure stable product quality.

Is the cost and supply of raw materials stable?

Waste paper, as the main raw material, is widely available and inexpensive, which is an important advantage for egg carton production. Customers can purchase waste paper nearby, which reduces transportation costs and ensures the continuity of production.

Do I need any special technical support during the production process?

Shuliy egg box molding machine is easy to operate and can be learned in a short period of time even without specialized technicians. We also provide installation training and after-sales support to ensure smooth production.

Advantages of choosing Shuliy egg carton machine

As a professional egg carton machine manufacturer, Shuliy is committed to providing customers with high-quality equipment and comprehensive services. By choosing Shuliy egg carton making machine, you will get the following advantages:

- Reliable quality of equipment: made of durable materials to ensure the stability and long life of the equipment.

- High degree of automation: fully automatic or semi-automatic production line can be selected according to the demand, which improves the production efficiency and reduces the labor cost.

- A variety of production options: whether small entrepreneurs or large factories, you can find the right production equipment.

- Perfect after-sales service: provide installation guidance, operation training and long-term technical support to ensure customers’ production without worry.

Contact us now!

If you are planning to invest in egg carton production, please feel free to contact us for a detailed equipment quotation and factory planning advice. We will provide you with a customized production solution to help you start your egg carton manufacturing business successfully! Act now to make your egg carton production more efficient and environmentally friendly!