Shuliy fully automatic waste tire recycling line is designed to process waste tires ranging from 900–1200mm in diameter into 10–16mm granules. These granules can be further ground into rubber powder(5-40 mesh) for high-value utilization. This tyre recycling machine line is highly efficient, automated, and low-labor, becoming an urgent need for many recyclers and investors. We offer two standardized configuration solutions tailored to different customer scales and requirements. Welcome to continue reading for more tire recycling solution details!

Two configurations of fully automatic waste tire recycling line

Configuration 1: Tire debeader + cutting machine process

This configuration process structure:

Wire Drawing Machine → Cutting Machine → Shredder → Rubber Powder Machine → Nylon Air Classifier → Rubber Powder Collection Conveyor System

This recycling line also utilizes conveyor belts, automatic storage systems, etc.

Suitable for processing:

- 900–1200mm truck tires, small construction tire sidewalls

- Customers requiring stable recycling volumes and clean steel wires

- Enterprises seeking higher rubber powder purity

Advantages of this 900-1200mm tire powder recycling line:

- First removing steel rims with a wire drawing machine, reducing blade wear.

- Quickly cutting tires into pieces with a cutter, enhancing shredding efficiency.

- Fully automated conveying + storage system, saving labor.

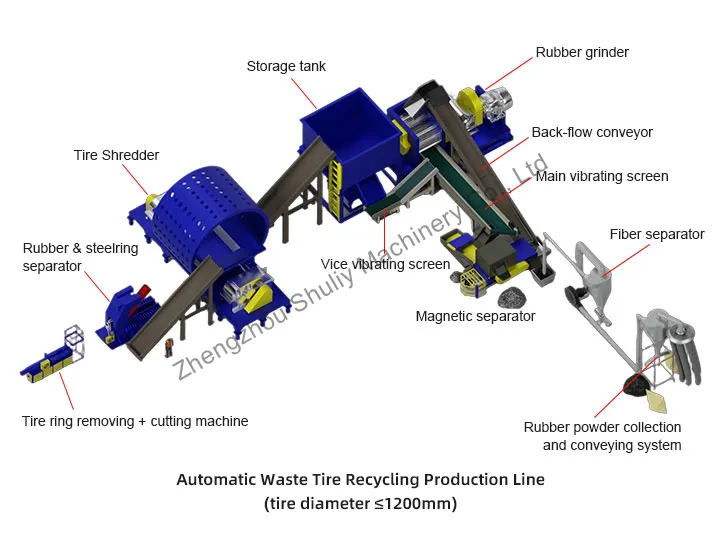

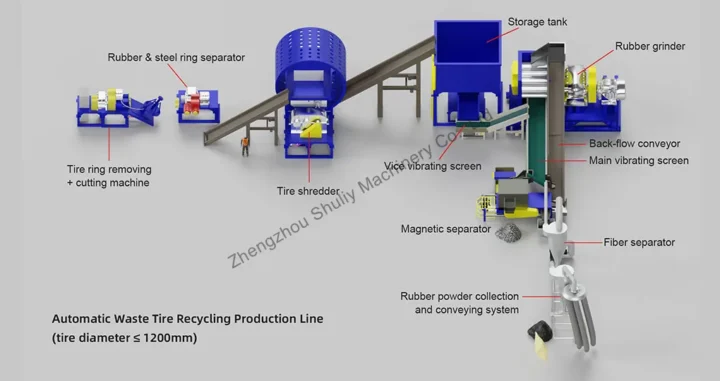

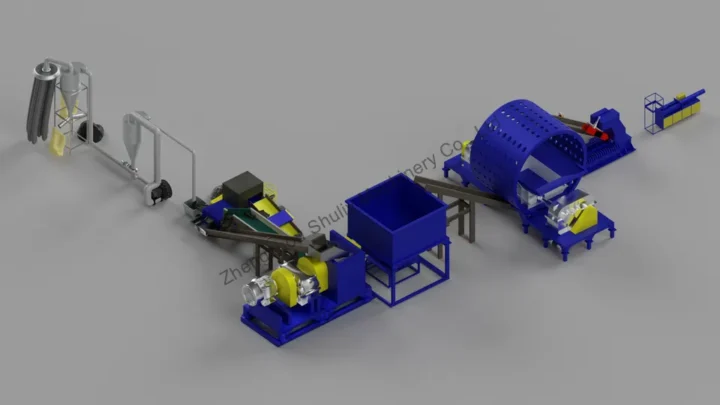

Configuration 2: Tire ring removing and cutting machine + steel ring separator process

This kind of waste tire recycling line structure process:

Integrated Ring Cutting and Severing Machine → Steel Ring Separator → Shredder → Rubber Powder Machine → Nylon Air Classifier → Rubber Powder Collection Conveyor System

The conveyor and storage bin are definitely required during the tyre powder manufacturing process.

Suitable for:

- Clients with limited space but seeking higher efficiency

- Users requiring simultaneous tire bead removal and cutting

- Fully automated factories aiming to minimize manual labor

Advantages of Shuliy tire recycling production line:

- Integrated machine completes rim cutting + block cutting in one pass, boosting efficiency by 40%.

- More thorough steel rim separation for easier subsequent shredding.

- Higher overall automation level across the line, reducing labor requirements

Advantages of Shuliy fully automatic tire recycling machine line

- Highly automated with minimal labor requirements

- The entire waste tire recycling line employs intelligent conveying systems and automated storage systems to achieve automatic material flow.

- Typically, only 2–3 workers are needed to operate the entire line, significantly reducing labor costs.

- Exceptional production capacity

- Depending on configuration:

- Output ranges from 800kg/h to 5000kg/h.

- Suitable for small workshops to large-scale commercial recycling enterprises.

- Depending on configuration:

- High rubber powder purity & adjustable particle size

- The nylon air separation system effectively separates fibers.

- The magnetic separation system further enhances steel wire removal.

- Final output: 10–16mm rubber pellets ready for grinding mills.

- Capable of producing:

- TDF fuel rubber

- Granular rubber

- 10–40 mesh rubber powder

- Capable of producing:

- High equipment durability and low maintenance costs

- In this rubber powder machine line, tire shredder blades are crafted from Cr12MoV alloy steel.

- Critical components reinforced for high-intensity operations.

- Modular design facilitates easy replacement and maintenance.

- Customizable voltage and factory layout

- Support 380V/400V/415V/220V, 50/60Hz configurations.

- 3D layout diagrams + process flow charts provided based on the customer site.

- Support OEM/ODE retrofits and production capacity upgrades.

- Extensive global case studies, proven reliability

- Shuliy tire recycling lines exported to:

- Australia, USA, Chile, Saudi Arabia, South Africa, India, Malaysia, Kenya, UAE, etc.

- Offer installation commissioning, operator training, and after-sales support.

- Shuliy tire recycling lines exported to:

Why choose Shuliy waste tire recycling line?

- Two proven configurations to meet diverse client needs

- Fully automated process, reducing labor by 40–60%

- High-efficiency shredding system + high-purity rubber powder output

- Durable equipment with extended blade lifespan

- Global case studies + professional after-sales team

- One-stop service for line design, production, shipping, and installation

What are the target customers to buy tyre recycling machine plant?

- Waste tire recycling plants

- Environmental recycling enterprises

- Government projects or tender projects

- Investors seeking to specialize in rubber powder, granulated rubber, or TDF

- Manufacturers of recycled rubber, pavement materials, or track materials

Contact us for a quote!

If you require:

✔ Free configuration solutions

✔ Complete line pricing

✔ Actual equipment operation videos

✔ Local customer case studies

✔ Factory layout diagrams

Feel free to contact us anytime. We will provide a comprehensive proposal about the waste tire recycling line as soon as possible.