Shuliy textile fiber cutting machine is specially designed for cutting various textile materials such as clothing, worn fabrics, glass fiber, aramid fiber, synthetic fiber, etc. into small pieces. It’s commonly used for recycling various waste textiles to make a profit.

This machine has a capacity of 500-3000kg per hour. Also, it has a cutting size of 5-300mm and a cutting thickness of 20-60mm.

Shuliy fabric cutting machine features highly efficient cutting, wide applications and cost-effectiveness. Also, it matches with the conveyor belt to feed or discharge the textile waste, which is more convenient.

Our waste cloth cutting machine is very popular in the world textile recycling industry. It has been exported to many countries, like Bangladesh, Mexico, Italy, etc. If you want to carry out fibre waste recycling, welcome to contact us. Our professional team will provide you with the best solution according to your needs.

Features of textile fiber chopping machine

- Capacity ranging from 500-3000kg/h. Our textile cutting machine can shred fabric of 500-3000kg per hour. Compared with the traditional way, it’s very efficient.

- Handle fabric, cloth, leather, waste yarn, cotton wool, etc. The fiber shredder machine can process a wide range of raw materials. In addition to those, there are chemical fiber, linen, clothing, non-woven fabrics, etc.

- Adjustable cutting size of 5-300mm and thickness of 20-60mm. Through using different blades, you can achieve it.

- Easy operation. You can use this machine by pressing the button on the machine side. It’s very easy.

- Take up less space. Shuliy designs this machine with compact structure to meet the market trend. The machine size is 1865*1120*1220mm, 3500*1200*1300mm, or 6000*1000*1100mm. It occupies less space in the waste textile processing plants.

- Factory direct sales. We manufacture and sell textile fiber cutters by ourselves. Thus our machine is cost-effective in the world market.

- Customizable plug and voltage. According to your needs, we can customize the plug and voltage to make them fit your use requirements.

Technical data of fiber waste cutting machine

| Model | Capacity | Power | Cutting size | Cutting thickness | Dimension |

| SL-800 | 500-800kg/h | 7.5kw | 5—300mm | 20mm | 1865*1120*1220mm |

| SL-1200 | 800-1200kg/h | 15kw | 5—150mm | 30mm | 3500*1200*1300mm |

| SL-1600 | 1000-3000kg/h | 18kw | 5—150mm | 30-60mm | 6000*1000*1100mm |

Here we list 3 models of fiber shredders for sale. Our textile waste cutting machine can handle 5-300mm fabrics with a thickness of 20-60mm.

When you choose a suitable fabric cutting machine, these parameters are for your reference. If you want professional suggestions, please tell us your requirements for the cut thickness and capacity. Our professional sales team will recommend a suitable one to you.

What materials can be chopped by textile fiber cutting machine?

Our waste cloth cutting machine has a wide range of applications. Below we will introduce what materials can be cut.

It can cut soft fiber, clothing offcuts, textile waste yarn, silk, waste clothes, chemical fiber, glass fiber, paper, hemp, fishing nets, sponges, fabrics, glass fiber, rock wool, leather, industrial silk, plastic film, non-woven fabrics, cotton wool, and others.

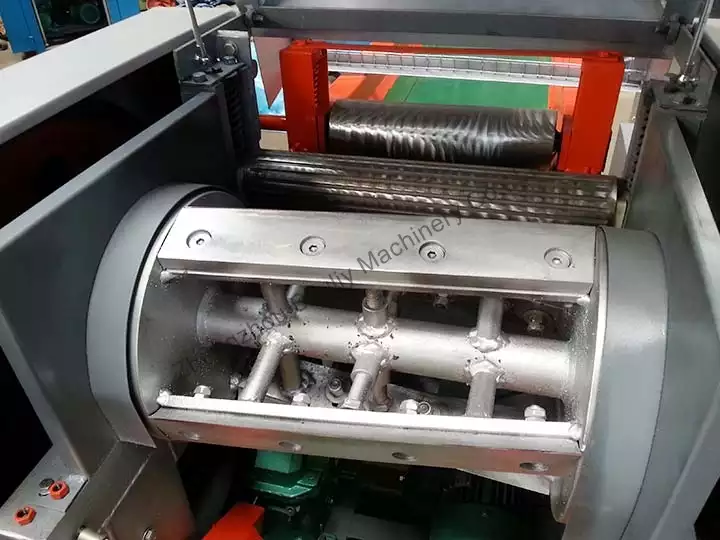

Structure of textile fiber cutting machine

The structure of a textile waste cutting machine consists of the main body, the tooling system, the control panel and the conveyor system.

- The body is usually constructed of sturdy metal with a stable base.

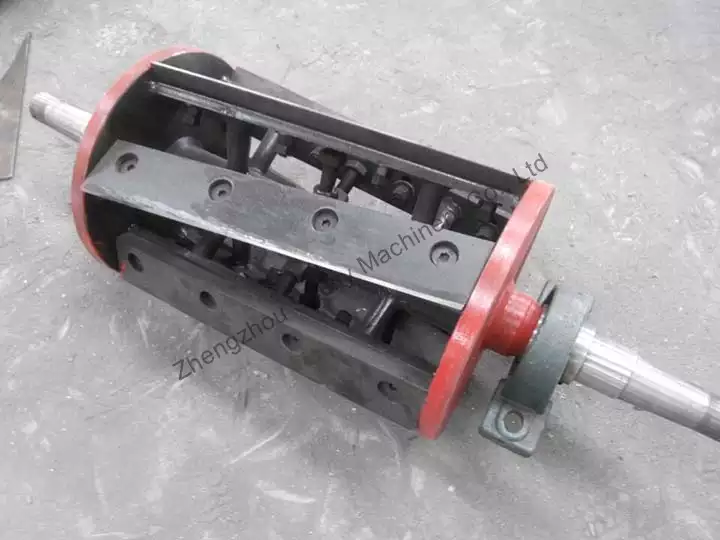

- The tooling system consists of rotating blades for cutting fibers.

- The control panel is used to set cutting parameters such as length and speed to ensure accurate cutting.

- A conveyor system feeds the fibers to be cut into the tool area for continuous cutting.

These components work in tandem to enable the textile fiber cutter to cut a wide range of fiber materials efficiently and accurately, increasing productivity.

Working principle of waste cloth cutting machine

The working principle of Shuliy fabric shredder is to mechanically cut waste fabrics into rags or strips of required sizes.

- Firstly, you can place the waste fabric in the cutting area and start the machine.

- The cutter system built into the textile waste cutter begins to rotate, cutting the fabric into the specified shape and size.

- Our waste fabric cutting machines also adopt automatic feeding. It can continuously feed the fabric into the cutting area for increased efficiency.

- Finally, the required fiber pieces are discharged from the machine outlet.

Our textile fiber cutting machine has adjustable cutting parameters to accommodate different types and thicknesses of fabric. If you want details, get in touch with us now for more information!

Fabric cutting machine package and delivery

The packaging and delivery of textile fiber cutting machines usually undergo a rigorous process to ensure the safety and integrity of the product.

- In terms of packaging, these machines are usually packed in sturdy wooden crates or steel frames to protect the machine from damage during transit.

- Cushioning materials, such as foam or airbags, are used internally to protect against shocks and impacts.

- Delivery is handled by a specialized logistics company that will ensure that the machine is safely delivered to the location specified by the customer.

- Before delivery, a final inspection and test of the machine is carried out to ensure that it is working correctly.

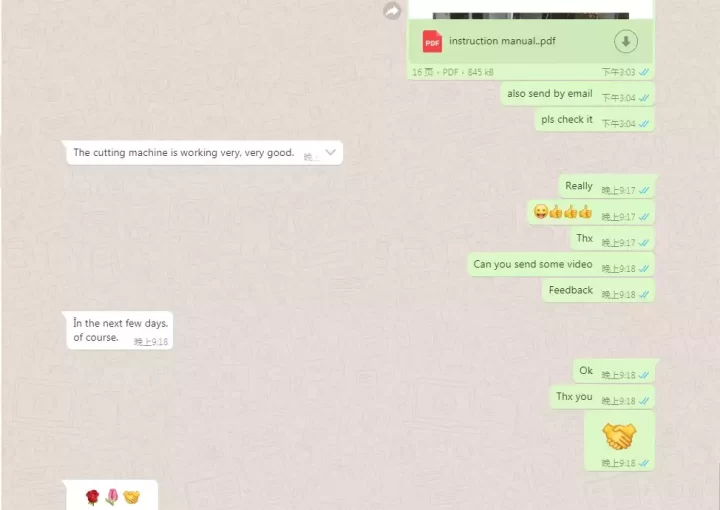

Customer feedback about textile fiber cutting machine

After you receive the textile cutting machine and use it for some time, you find that it is very useful and the effect is very good.

- Some customers praise the efficiency and precision of the textile waste cutting machine. They describe it as an indispensable tool in the textile waste recycling business.

- Some customers particularly highlight the versatility of the cutting machines. It can adapt to different types and sizes of fiber materials, increasing flexibility in production.

- In addition, customers find that the fiber cutter is easy to operate, reducing training costs.

There are some reviews about the textile fibre cutting machines for your reference.

Matched equipment with textile fiber cutting machine

For textile waste recycling, this machine always works with the cotton opener and fiber cleaning machine. This matched textile recycling machine line is fully automatic and highly efficient.

Do you know fiber cutting machine price?

Textile fiber cutting machine prices are often influenced by several factors including model, brand, configuration and competition between suppliers.

To obtain the most accurate pricing information, you can directly contact us for a detailed quote and product information.