Pillow making machine is manufacturing pillows automatically line, first cotton opening, then filling. It consists of cotton opener and pillow stuffing machine, mainly for various pillows, toys, and dolls production.

The whole configuration is usually a combination of opening, filling and sometimes weighing & pressing, in order to make the pillow more neat and beautiful. It features full automation, high efficiency and great performance.

When you want to make pillows, cushions and other filling products, please contact us for the best offer!

Types of polyester fiber opening and filling machines for sale

Our pillow making machine configurations are usually divided into two categories based on the type of filling machine: single-head filling and double-head filling.

Single-head cushion stuffing machine only handles one pillowcase at a time, while double-head automatic pillow filling machine has two filling heads and can handle two pillowcases at the same time, thus increasing productivity.

Both configurations have their own advantages and the choice depends on production needs and capacity requirements.

Fiber opening and filling machine- single head filling

This kind of pillow cotton filling machine typically has a single filler head for processing one pillowcase. This configuration is suitable for small or low-volume production environments because it can only process one pillow at a time.

However, with a smaller footprint and ease of operation and maintenance, a single-head filler may be an affordable option for small production shops or start-ups.

| Model | SL-3B | SL-3B-1 |

| Capacity(kg/h) | 120-150 | 120-150 |

| Voltage | 380V/50Hz | 380V/50Hz |

| Power(kw) | 5.75 | 6.5 |

| Dimensions(mm) | 3700*900*1200 | 4300*900*1800 |

| Weight(kg) | 470 | 800 |

As shown in the table above, these are our 2 hot selling models. If you want to start a new business or small-scale pillow production, the above models are your best choice.

Double-head quantitative filling machine

This double-head cotton filling machine, on the other hand, has two filling heads and can process two pillowcases at the same time, making it faster and suitable for mass production.

It increases productivity and reduces labour costs, but typically requires a larger workspace and more complex operation and maintenance. Double-head fillers are typically used in large textile mills and high-volume pillow lines to meet market demand.

| Model | SL-3B-4A | SL-3B-4B | SL-5C-2(Flattening platform) |

| Capacity(kg/h) | 120-150 | 120-150 | / |

| Air pressure(Mpa) | 0.6-0.8 | 0.6-0.8 | 0.6-0.8 |

| Voltage | 380V/50Hz | 380V/50Hz | 380V/50Hz |

| Power(kw) | 7.25 | 8.25 | 1.5 |

| Dimensions(mm) | 4600*1000*1200 | 5600*1000*2200 | 1100*900*1200 |

| Weight(kg) | 600 | 800 | 60 |

There is also flattening data shown above, as our equipment can be tapped after filling to make the pillow fill more evenly. The configuration is shown as below:

Working process of pillow making machine

Pillow filling line usually consists of two main parts: the opening machine and the filling machine, which work in a certain order. The following is a brief introduction to the pillow making line:

Cotton opening

Cotton opener is the first process of pillow filling plant, a similar function to the textile waste cutting machine.

It is mainly used to process raw filling materials such as cotton, polyester fibres, etc. in order to unravel, break up and comb the fibres.

The purpose of the opener is to remove impurities, short fibres and irregularities, as well as to disperse the fibres in order to obtain a more homogeneous filling material.

Pillow filling

Pillow stuffing machine is the second process of the filling line, immediately after the opening machine.

Its main function is to inject the filling material that has been processed by the pillowing machine into the pillowcase to create the pillow.

The filling machine is usually equipped with a precise control system that ensures that the quantity and density of the filling material meet the requirements for consistent pillow quality.

Applications of pillow making machine plant

The main application of this fiber opening and pillow filling machine is to manufacture various types of pillows, such as dolls, neck pillows, cuddle pillows, toys, etc.

It can handle different types of filling materials to meet the demand for different types and sizes of pillows in the market. Applications for this pillow making machine plant include bedding, home furnishings, hospitality, and other places where pillows are needed.

Main components of pillow making machine

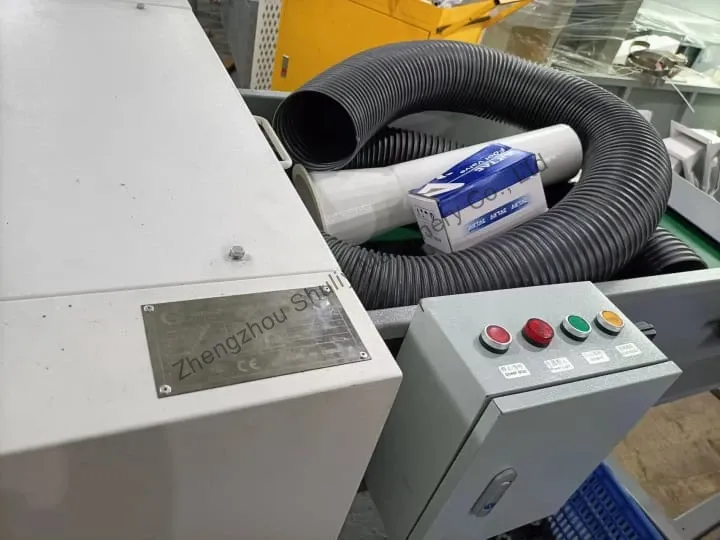

This combination mainly has an empty electrical cabinet, hoses, openers, fillers, etc. Sometimes weighing, tapping, etc. are added, depending on your needs.

How about the pillow making machine price?

The pillow making machine price varies depending on a number of factors, including model, specification, brand, performance, production capacity and region.

Typically, machines with higher specifications, well-known brands, advanced performance and greater production capacity are relatively more expensive.

In order to obtain accurate pricing information, it is recommended to contact Shuliy Machinery directly with detailed requirements so that we can provide you with a customized quote, as well as to consider the market competition and regional differences in order to make an informed purchasing decision.