EPS foam granulating line, also known as plastic foam recycling line is designed for foam material recycling, like EPE, EPS. It has a handling capacity of 150-300kg/h, but we offer customized service. So, we can customize it specifically for you or configure it flexibly for you if you want to process large volumes.

Also, for foam recycling, we have foam cold press, EPS foam heat melting machine for sale. If you have any need, come and contact us at any time!

How to granulate EPS foam and EPE foam into pellets?

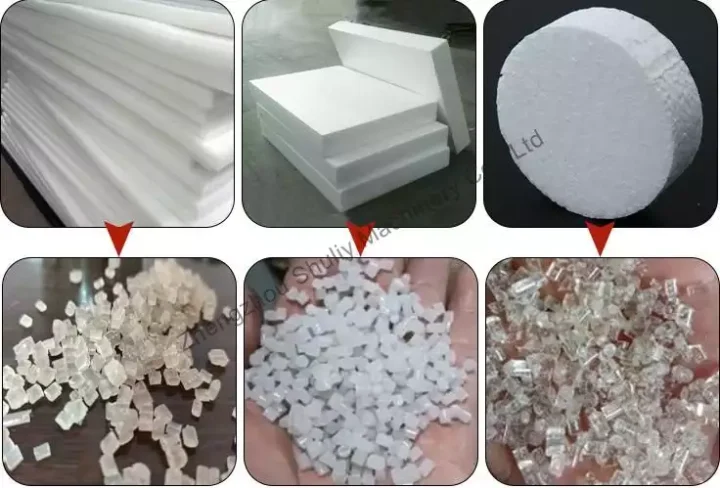

Together, the following steps complete the granulation process of EPS foam and EPE foam, converting waste foam into recycled pellets for effective recycling and reuse of resources. See detailed steps:

Foam preparation

Collect waste EPS foam and EPE foam to ensure that they do not carry too many additional impurities. Clean raw materials help to improve the granulation quality.

EPE EPS foam crushing

The raw material is fed into a crusher for initial crushing to break the waste foam into small pieces. This helps in the subsequent extrusion and pelletizing process.

Pelleting

The crushed foam material is moulded into granules through the foam granulator, so as to be more flexibly applied to the production of new foam products.

Cooling and cutting

Cool granulated foam particles and then cut them into required sizes to meet different production requirements.

Machine used in EPS foam granulating line

In the EPE EPS foam granulating line, the below machines are necessary to make foam pellets. Let’s together learn about it.

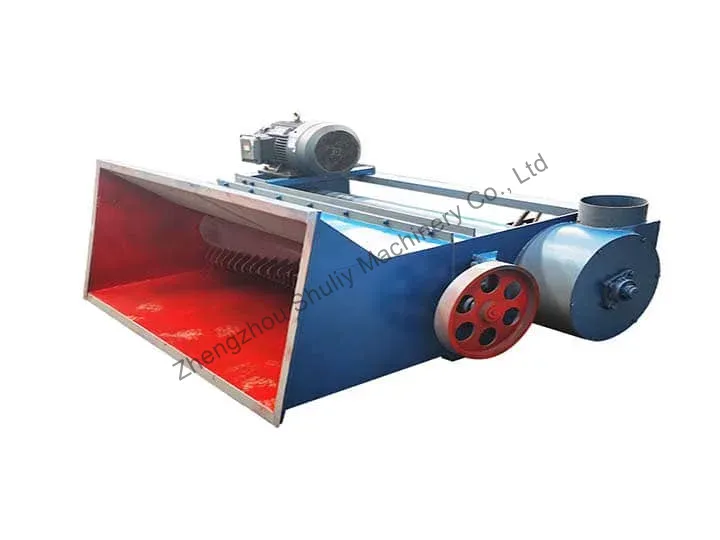

It is used for preliminary crushing of waste EPS foam, crushing large pieces of foam into small particles to prepare for the subsequent steps.

This is the key equipment of the whole EPS foam granulating line, used to extrude and form foam pellets. Through the extruder, the raw foam material is heated, melted and extruded through the die to form pellets of the required size and shape.

Cooling tank

The freshly extruded foam pellets have a certain temperature and need to be cooled to prevent sticking and deformation.

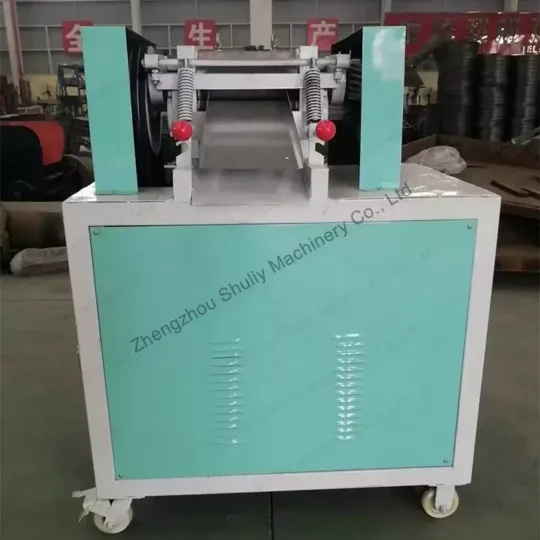

Pellet cutting machine

It’s used for the final cutting of the cooled foam pellets to meet product specifications and requirements. This ensures the consistency and quality of the granules.

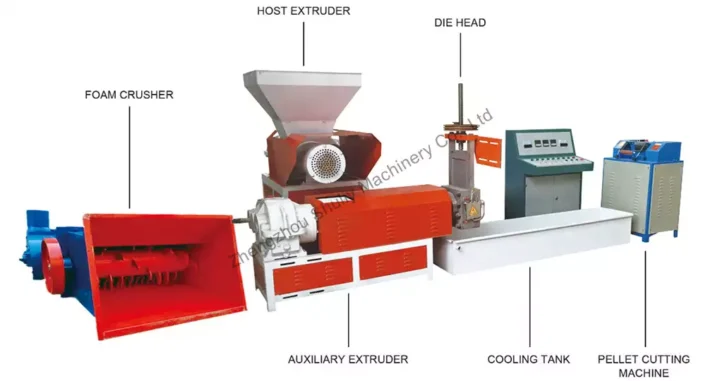

Components of EPS foam recycling and pelletizing machinery line

To be honest, the main structure for the EPS foam granulating line is very easy to understand. It consists of foam crusher, host extruder, auxiliary extruder, die head, cooling tank and pellet cutting machine.

This foam pelletizing line covers the main recycling machines handling EPE EPS foam. If you want to know more, please contact us at any time for more details!

Benefits of recycling EPE EPS foam

Why use EPS foam granulating line? Refer to the below advantages of foam recycling:

- Resource reuse: Recycling EPE EPS foams means efficient reuse of these materials, reducing the need for new raw materials. Through recycling, waste foam can be converted into useful recycled materials.

- Environmental reduction: Foam products are often made from petroleum-based materials, and recycling these materials helps to reduce dependence on finite fossil fuels, lowering the carbon footprint and mitigating climate change.

- Waste minimization: Foam products take up a lot of volume when they are discarded, but by recycling them, the amount of waste going to landfills can be effectively reduced, easing pressure on landfill sites.

- Energy savings: The manufacture of new foam products by EPS foam granulating line requires a large amount of energy, but recycling reduces energy consumption and lowers the environmental impact of the production process.

How to find a reliable EPS foam granulating line machinery manufacturer?

When choosing a manufacturer of EPE Styrofoam pelletizing machine, there are several key factors to consider to ensure you find a reliable partner:

- Reputation: Check out a manufacturer’s reputation, and obtain it through customer reviews and the like. Reliable manufacturers usually have a good reputation, such as Shuliy Machinery.

- Product quality: Find out in detail about the quality of the manufacturer’s products, such as parameters, machine materials, durability, etc. Our foam recycling machine at Shuliy is made from high-quality materials, resulting in a high-quality end product with good performance and a long service life.

- After-sales service: Pay attention to the after-sales service provided by the manufacturer, including maintenance, training, technical support and so on. As a responsible manufacturer, we will provide all-around after-sales support to ensure that you get timely help in the process of using the EPS foam granulating line.

- Customization: If your needs are more specific, choosing a manufacturer with customization capability will be more advantageous. We’ll be able to provide customized solutions based on your actual needs.

When looking for a plastic foam pelletizing line manufacturer, consider the above factors and choose a reputable manufacturer that matches your needs and will provide strong support for your production.

Get in touch with us to start foam recycling!

If you have waste foam materials to dispose of or have any questions about foam recycling lines, please feel free to contact us. We offer a full range of foam recycling solutions to ensure that waste foam is processed efficiently and environmentally friendly, and converted into valuable recycled materials.

Through cooperation, we are contributing to environmental protection together and opening a new chapter of sustainable development!