A textile factory in Croatia is facing a large number of fibre waste disposal problems, in order to achieve the goal of resource recycling and environmental protection, they decided to establish their own fibre waste recycling line. They chose Shuliy’s waste cloth cutting machine among many other machines, mainly based on the following considerations:

- Efficient cutting performance: With its excellent cutting performance and handling capacity, our fibre cutter is able to quickly cut all types of fibre waste into sizes suitable for reprocessing.

- Stability and durability: Shuliy waste cloth cutting machine uses high-quality materials and precision manufacturing process, to ensure that the equipment in high-load working conditions can still maintain stable operation and long life.

- Energy saving and environmental protection: Our fabric waste cutting machine design focuses on energy saving and environmental protection, reducing energy consumption and noise pollution, in line with the sustainable development strategy of the factory.

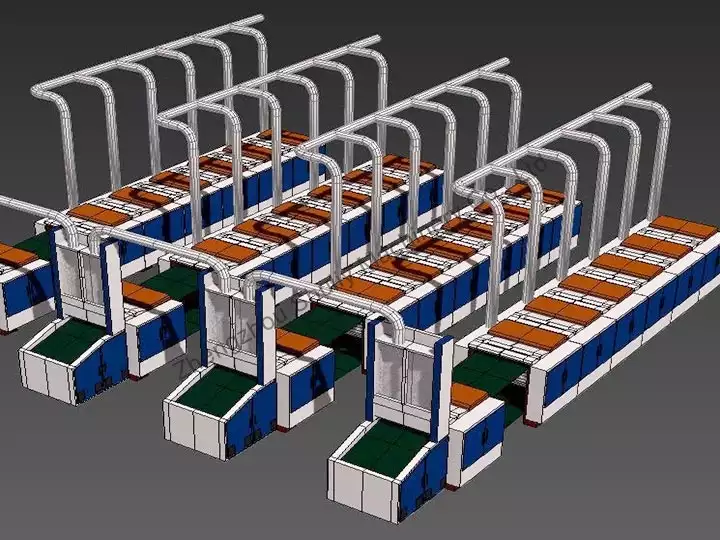

Equipment configuration and line construction

In the configuration of fibre waste recycling line, Croatian customers fully consider the efficiency and effectiveness of the entire production process, the following is how they combine with the Shuliy waste cloth cutting machine for equipment configuration:

Scrap pre-processing

First, the scrap screening and cleaning equipment is used to remove impurities and dust from the fibre scrap, improving the quality of subsequent processing.

Fibre cutting

Next, the pre-treated fibre scrap is precisely cut using a fabric chopping machine to ensure that the regenerated fibres are of the right length and shape for reprocessing.

Opening and cleaning

Further process fibre segments with opener and multi-roller cleaner for good quality textile products.

Waste cloth cutting machine operation and results in Croatia

The Croatian customer’s plant has achieved significant results since the start of operation of the fibre waste recycling line equipped with Shuliy waste cotton recycling machine:

- Improving resource utilization: Through the efficient fibre cutting and recycling process, the plant has successfully transformed discarded fibre waste into valuable renewable resources and improved resource utilization.

- Reducing environmental pollution: The operation of the textile waste recycling line has reduced the discharge of waste from the plant, reducing the impact on the environment and complying with local environmental regulations.